Method for coating surface of polyimide nanofiber membrane with boehmite ceramic layer

A nanofiber membrane and polyimide technology, applied in fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problem of limited improvement of ionic conductivity and thermal stability, increase of separator thickness and quality, decrease of battery energy density, etc. problems, achieve high wettability and thermal stability, reduce mass and thickness, and increase energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

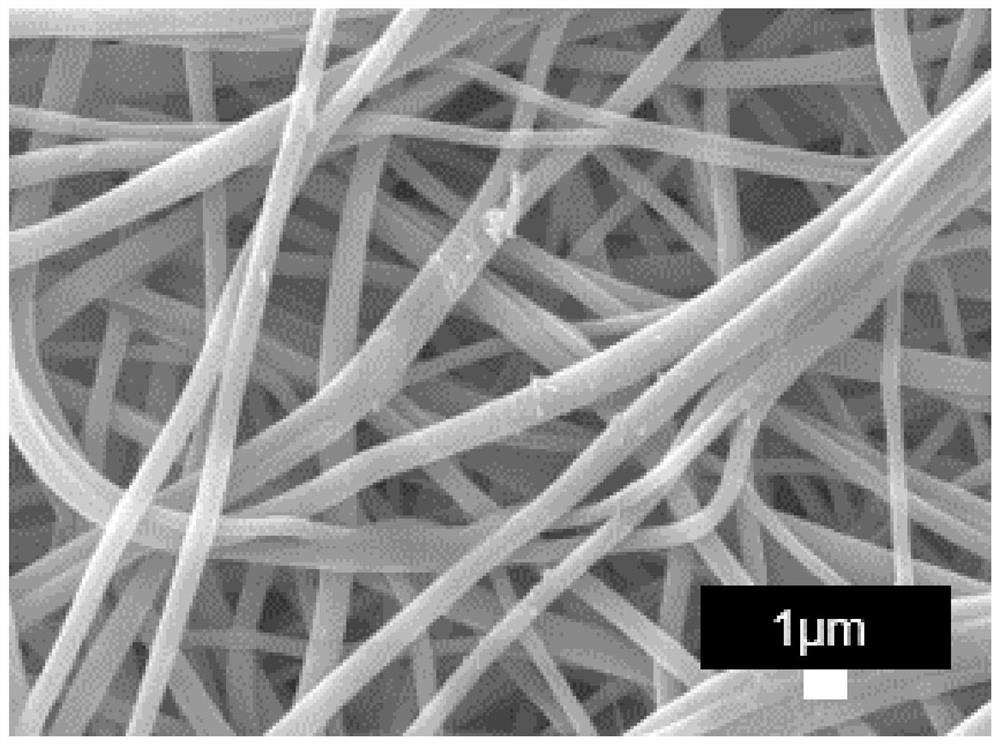

[0038] (1) Take 4.17g of anhydrous aluminum chloride and slowly add it into 80ml of deionized water to make it completely dissolved to make a 0.4mol / L anhydrous aluminum chloride solution; (2) Weigh the homobenzene with a molar ratio of 1:1 Tetraformic dianhydride (PMDA) 2.0g, 4,4'-diaminodiphenyl ether (ODA) 1.84g, all ODA dissolved in 30ml of N,N-dimethylformamide (DMF) solvent, mechanically stirred After the ODA is completely dissolved in DMF, add PMDA in batches under the condition of an ice-water bath to obtain a polyamic acid solution with a moderate viscosity, then mechanically stir for 2 hours to homogenize, and finally put the polyamic acid solution into a 20ml syringe , using electrospinning technology to prepare polyamic acid nanofiber membranes, the specific parameters of the electrospinning process are spinning voltage: 17kV; spinning temperature: room temperature; spinning humidity: 30%; diameter of syringe needle: No. 12; receiving roller Speed: 400rpm; Receivin...

Embodiment 2

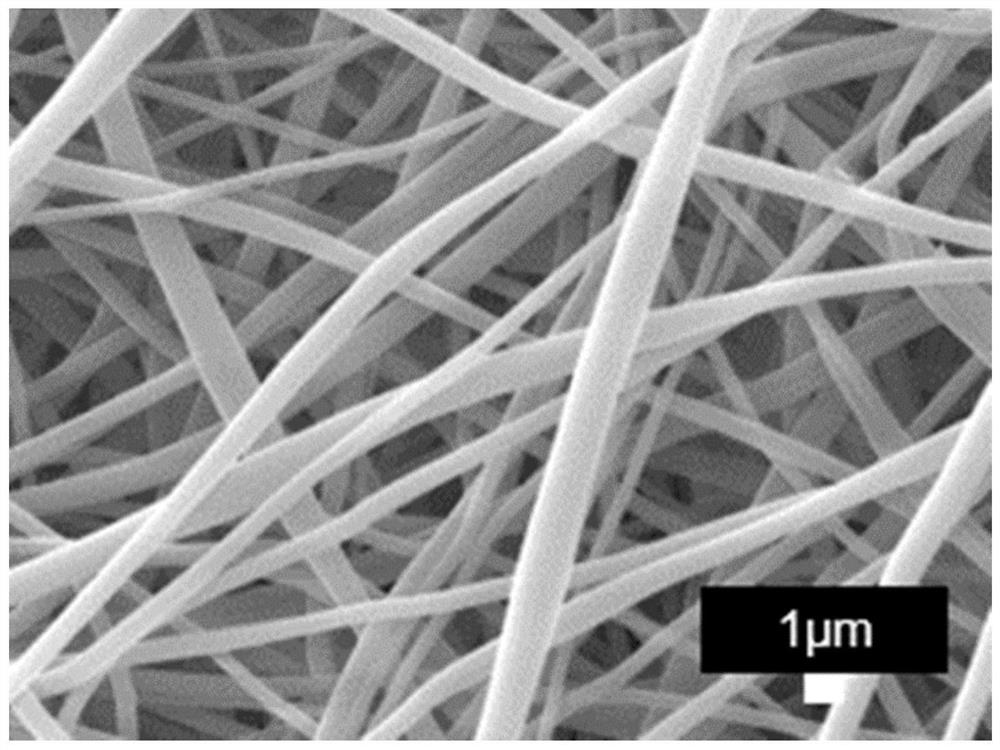

[0040] (1) Take 4.17g of anhydrous aluminum chloride and slowly add it into 80ml of deionized water to make it completely dissolved to make a 0.4mol / L anhydrous aluminum chloride solution; (2) Weigh the homobenzene with a molar ratio of 1:1 Tetraformic dianhydride (PMDA) 2.0g, 4,4'-diaminodiphenyl ether (ODA) 1.84g, all ODA dissolved in 30ml of N,N-dimethylformamide (DMF) solvent, mechanically stirred After the ODA is completely dissolved in DMF, add PMDA in batches under the condition of an ice-water bath to obtain a polyamic acid solution with a moderate viscosity, then mechanically stir for 2 hours to homogenize, and finally put the polyamic acid solution into a 20ml syringe , using electrospinning technology to prepare polyamic acid nanofiber membranes, the specific parameters of the electrospinning process are spinning voltage: 17kV; spinning temperature: room temperature; spinning humidity: 30%; diameter of syringe needle: No. 12; receiving roller Speed: 400rpm; Receivin...

Embodiment 3

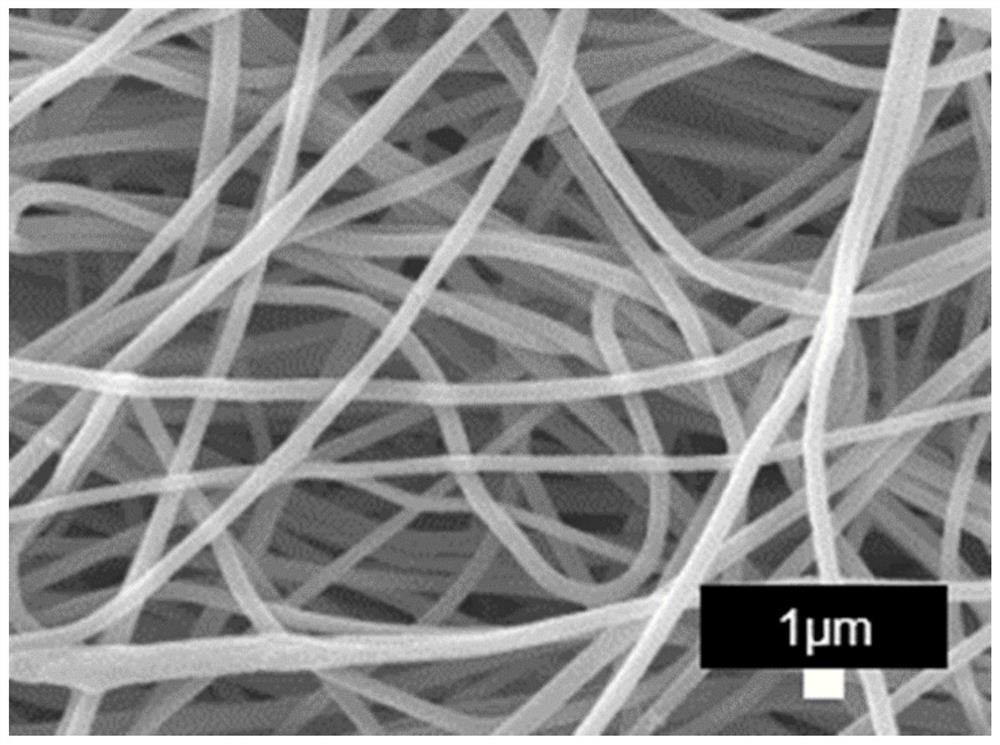

[0042] (1) Take 4.17g of anhydrous aluminum chloride and slowly add it into 80ml of deionized water to make it completely dissolved to make a 0.4mol / L anhydrous aluminum chloride solution; (2) Weigh the homobenzene with a molar ratio of 1:1 Tetraformic dianhydride (PMDA) 2.0g, 4,4'-diaminodiphenyl ether (ODA) 1.84g, all ODA dissolved in 30ml of N,N-dimethylformamide (DMF) solvent, mechanically stirred After the ODA is completely dissolved in DMF, add PMDA in batches under the condition of an ice-water bath to obtain a polyamic acid solution with a moderate viscosity, then mechanically stir for 2 hours to homogenize, and finally put the polyamic acid solution into a 20ml syringe , using electrospinning technology to prepare polyamic acid nanofiber membranes, the specific parameters of the electrospinning process are spinning voltage: 17kV; spinning temperature: room temperature; spinning humidity: 30%; diameter of syringe needle: No. 12; receiving roller Speed: 400rpm; Receivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com