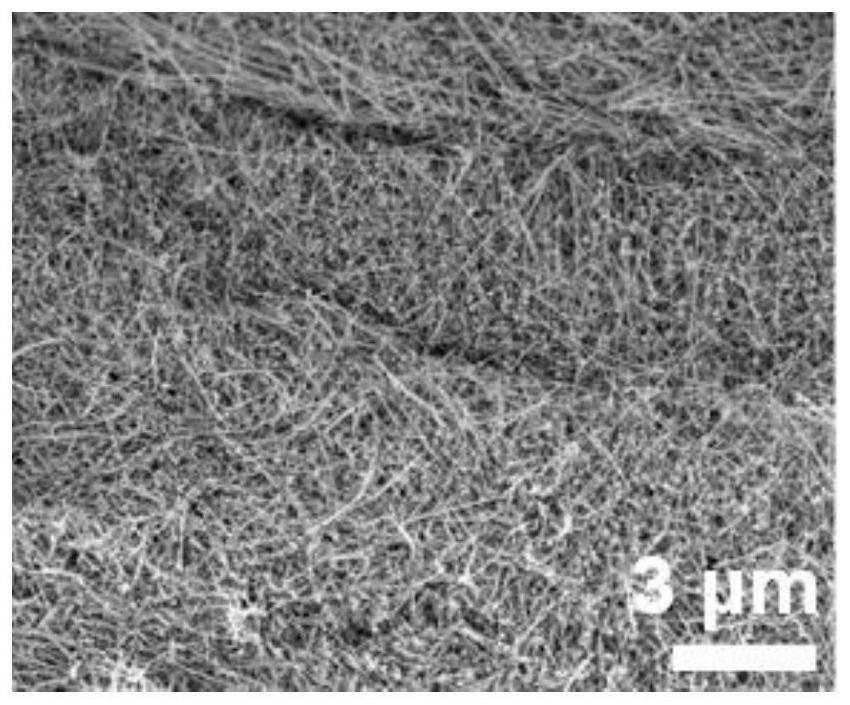

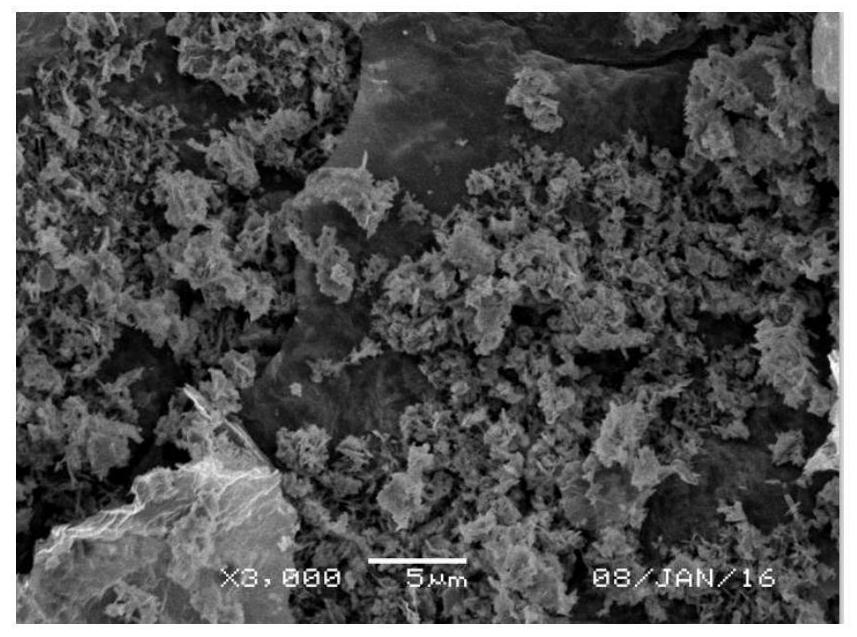

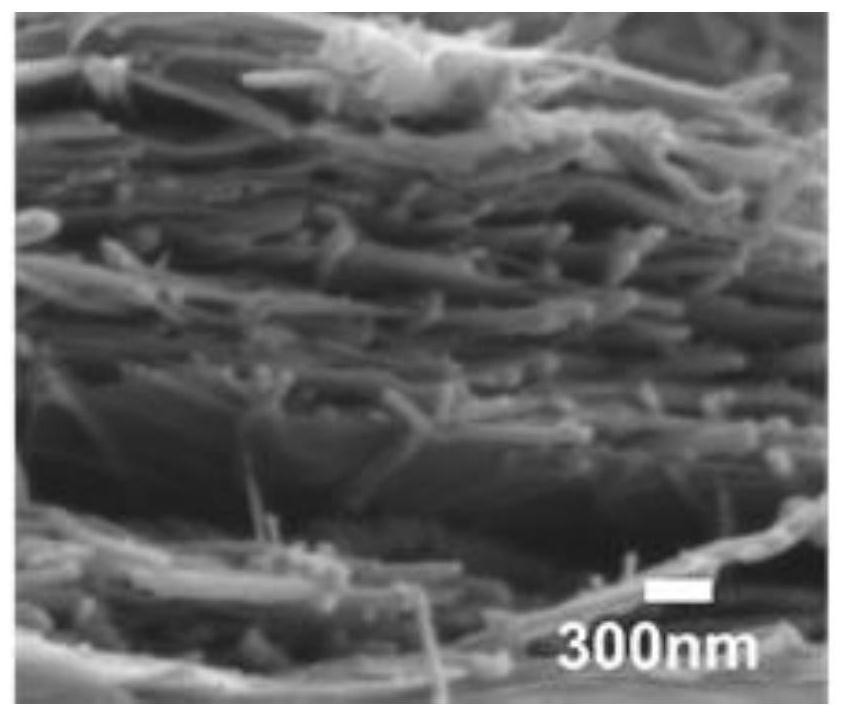

Graphene and nano-silver composite material and preparation method thereof

A composite material, graphene technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low conductivity and uncontrollable distribution of conductive nanocomposite fillers, prevent irreversible agglomeration, and facilitate flexibility. The effect of chemical and large printing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Step 1: Take 180ml of graphene oxide N,N-dimethylformamide (DMF) dispersion with a concentration of 10mg / ml and a sheet diameter of 45μm, then add 66ml of 25% hydrogen peroxide, and heat at 120°C , carry out secondary oxidation under reflux for 4h, and obtain carboxylated modified graphene oxide;

[0083] Step 2: Dissolve 0.6 g of S,S'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate (BDMAT) chain transfer agent in 10 ml of N,N-dimethylformaldehyde Amide (DMF) solution, then added to the first step reaction to generate hydroxylated modified graphene oxide solution, heated to 80 ° C and adjusted to a system pH of 3-4; then in an argon atmosphere, under the heating conditions reaction, to promote the esterification reaction between the carboxyl group on the BDMAT molecular chain and the hydroxyl group on the graphene sheet, grafting BDMAT on the surface of hydroxylated modified graphene oxide, realizing the grafting of BDMAT on the surface of graphene, and obtaining a gra...

Embodiment 2

[0090] Step 1: Take 200ml of graphene oxide aqueous solution with a concentration of 4mg / ml and a sheet diameter of 25μm, then add 100ml of a mixture of nitric acid and sulfuric acid with a volume ratio of 1:3, the mass fraction is 10%, and heat at 100°C , and reflux secondary oxidation for 6h to obtain carboxylated modified graphene oxide;

[0091] Step 2: Dissolve 8g of 4-cyanopentanoic acid dithiobenzoate chain transfer agent (CPADB) in 50ml of aqueous solution, then add the first step reaction to generate hydroxylated modified graphene oxide solution, heat to 80°C; then in an argon atmosphere, react under this heating condition to promote the esterification reaction between the carboxyl groups on CPADB and the hydroxyl groups on the graphene sheet, and graft CPADB on the surface of hydroxylated modified graphene oxide, thereby achieving 4 - Cyanovaleric acid dithiobenzoate shields the hydroxyl group on the surface of graphene oxide to obtain graphene oxide chain transfer a...

Embodiment 3

[0097] Step 1: Take 300ml of graphene oxide aqueous solution with a concentration of 6mg / ml and a sheet diameter of 10μm, then add 150ml of 54g of potassium ferrate solution with a mass fraction of 10%, and carry out reflux secondary oxidation for 6h under heating conditions at 100°C , to obtain carboxylated modified graphene oxide;

[0098] Step 2: Dissolve 0.8g of 4-cyano-4-(ethylsulfanylthiocarbonyl)sulfanylvaleric acid chain transfer agent in 50ml of aqueous solution, and then add the first step to generate carboxylation modification Graphene oxide solution, heated to 80 ° C; then in an argon atmosphere, react under this heating condition to promote the carboxyl group on the 4-cyano-4-(ethylsulfanylthiocarbonyl)sulfanylvaleric acid and The hydroxyl group on the graphene sheet undergoes an esterification reaction, and 4-cyano-4-(ethylsulfanylthiocarbonyl)sulfanylvaleric acid is grafted on the surface of the hydroxylated modified graphene oxide, thereby realizing the 4- The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com