Anion exchange membrane with strong rigid structure and preparation method and application thereof

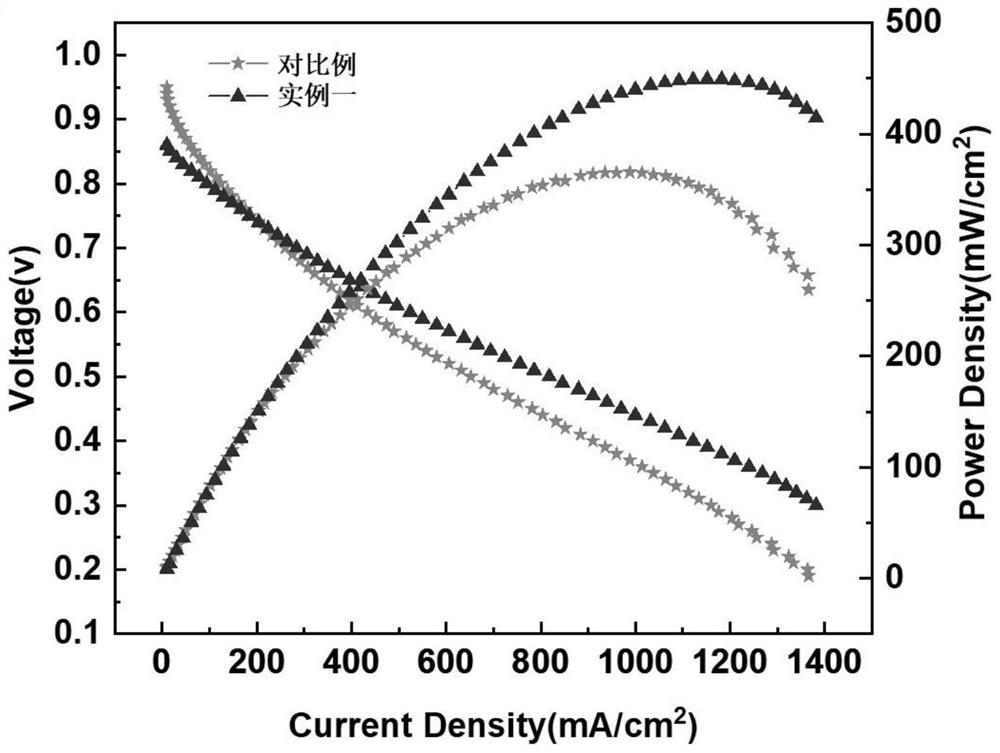

A technology of anion exchange membrane and rigid structure, which is applied in the field of anion exchange membrane with strong rigid structure and its preparation, which can solve the problems of limiting the performance and application of AEMs, the inability to make the membrane into ultra-thin layers, and insufficient rigidity, etc., and achieve excellent power density. and life, excellent life, and the effect of mild polymerization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

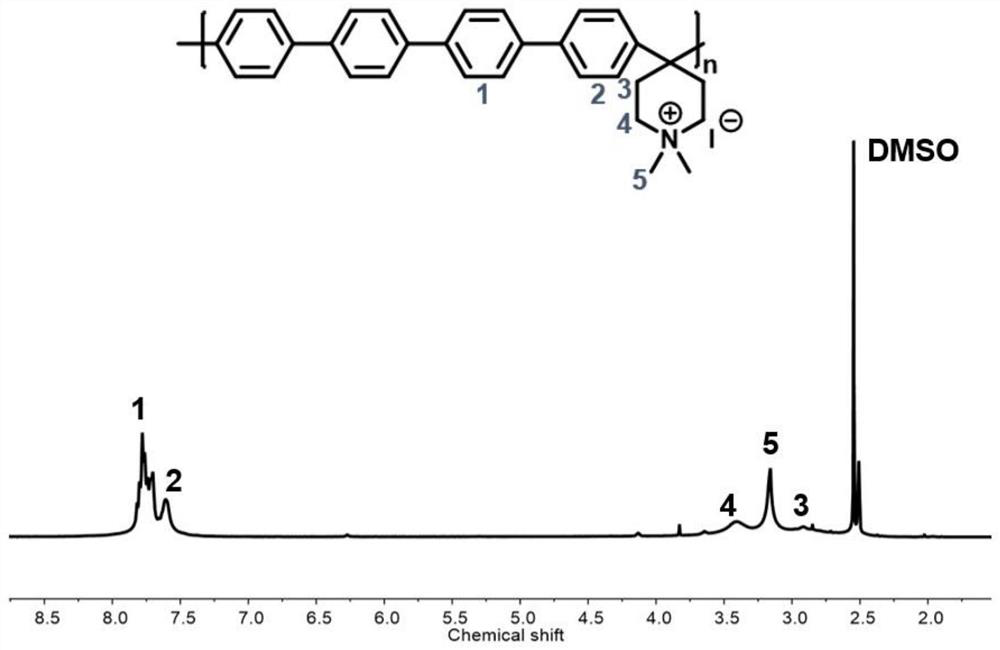

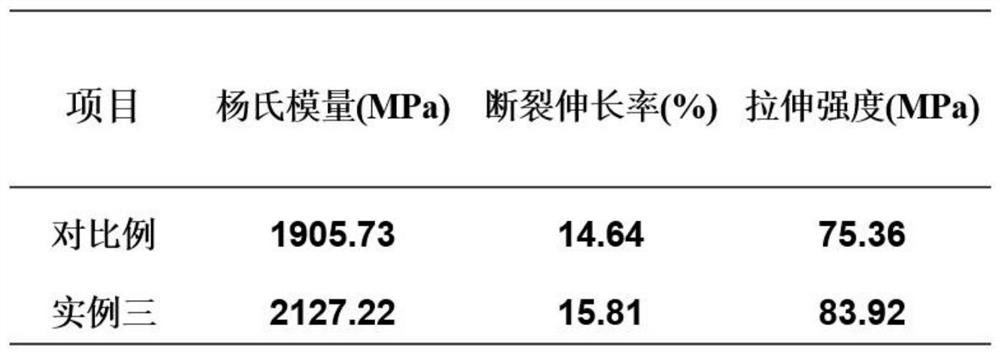

[0039] An anion exchange membrane with a strong rigid structure has a thickness of 4-100 μm, a Young's modulus of 2000-2200 MPa, a tensile strength of 80-100 MPa, and a copolymer comprising the following repeating structural units:

[0040]

[0041] where Ar is a divalent organic group containing an aromatic ring, R 1 and R 2 Represents the same or different substituents, n represents the degree of polymerization, which is a positive integer from 10 to 200, the weight average molecular weight is between 5000 and 800000, m is the molar percentage of the part containing p-quaterphenyl in the homopolymer, m Any number from 0 to 100.

[0042] The Ar is any one of the following groups:

[0043]

[0044]

[0045] The R 1 , R 2 Any one of the following groups:

[0046]

[0047] where X - on behalf of Br - , I - , Cl - , OH - 、HCO 3 - , and CO 3 2- , y=a positive integer between 1 and 10, R 3 , R 4 , R 5 , R 6 , R 7 are independently substituted by hydro...

example 2

[0060] A method for preparing an anion-exchange membrane containing a strong rigid structure, comprising the following steps:

[0061] (1) At room temperature, first dissolve p-quaterphenyl in dichloromethane, stir mechanically for 1 h, then add 7-bromo-1,1,1-trifluoro-2-heptanone monomer, and also dissolve in In the aforementioned solution, the aryl ketone molar ratio is 1:1.5, and the solution concentration is controlled at 20wt%;

[0062] (2) Add trifluoromethanesulfonic acid (TFSA) and trifluoroacetic acid (TFA) dropwise to the solution in step (1) at 0°C. The polymerization was initiated at -15°C, and then reacted at room temperature for 24h. After the reaction is completed, the solution is poured into methanol or ethanol to obtain a fibrous polymer. After several precipitation washes, wash with 1M potassium carbonate solution at 50°C to remove excess acid in the solution, filter and polymerize the obtained fibrous solid The product was boiled with water, filtered, and ...

example 3

[0072] At room temperature, first dissolve p-quaterphenyl in dichloromethane, stir mechanically for 0.5h, then add N-butyl-4-piperidone monomer, and dissolve in the aforementioned solution as well. The molar ratio of aryl ketone is 1:2, the solution concentration is controlled at 20wt%; the rest of the experimental steps and application steps are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com