Garbage pyrolysis waste gas purification system and process

A waste gas purification system and garbage technology, applied in incinerators, lighting and heating equipment, combustion product treatment, etc., can solve the problem of failure to effectively utilize the calorific value of flue gas, difficulty in meeting the requirements of environmental friendliness, and complicated treatment processes, etc. problem, to achieve the effects of lower gas temperature, good sulfur resistance, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

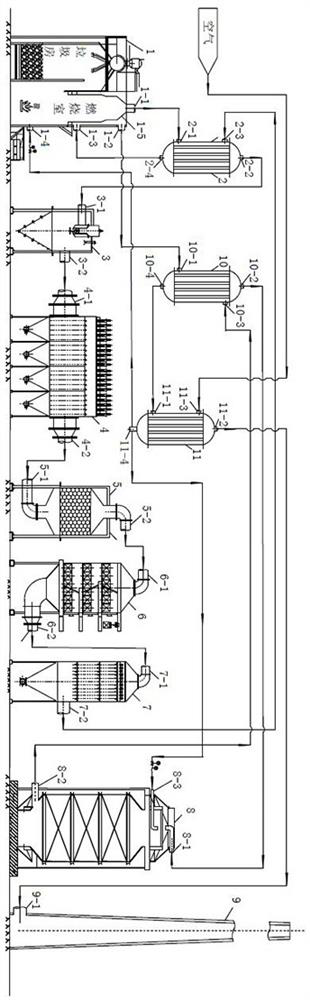

Image

Examples

Embodiment 1

[0043] The temperature in the combustion chamber of the waste combustion chamber 1 is 700℃, the temperature of the flue gas at the outlet is 180℃, and the flow rate of the flue gas is 1000m 3 / h, the flue gas enters the heat exchanger I for heat exchange and cooling, and the temperature is lowered to 122 °C; then the flue gas passes through the cyclone dust collector 3, the electrostatic collection and dust removal composite tar removal device 4, the activated carbon adsorption tower 5, and the dry desulfurization reactor 6. The dry dechlorination reactor 7 is processed to obtain a low-temperature preliminary purified gas, and the gas temperature is 60 °C;

[0044] Wherein, the desulfurizing agent used in the dry desulfurization reactor 6 is a mixture of 27.5g calcium oxide, 5g iron oxide, 7.5g calcium carbonate, 5g carbon slag, 2.5g cement and 8.3g silica sol (wherein SiO 2 30 wt.%) in a polyethylene beaker, grinding and mixing, and then dropwise add 30 mL of deionized water ...

Embodiment 2

[0049] The temperature in the combustion chamber of the waste combustion chamber 1 is 700℃, the temperature of the flue gas at the outlet is 183℃, and the flow rate of the flue gas is 1500m 3 / h, the flue gas enters the heat exchanger I for heat exchange and cooling, and the temperature is lowered to 128 °C; then the flue gas passes through the cyclone dust collector 3, the electrostatic collection and dust removal composite tar removal device 4, the activated carbon adsorption tower 5, and the dry desulfurization reactor 6. The dry dechlorination reactor 7 is processed to obtain a low-temperature preliminary purified gas, and the gas temperature is 62 °C;

[0050] Wherein, the desulfurizing agent used in the dry desulfurization reactor 6 is a mixture of 27.5g calcium oxide, 5g iron oxide, 7.5g calcium carbonate, 5g carbon slag, 2.5g cement and 8.3g silica sol (wherein SiO 2 30 wt.%) in a polyethylene beaker, grinding and mixing, and then dropwise add 30 mL of deionized water ...

Embodiment 3

[0055] The combustion chamber temperature of waste combustion chamber 1 is 700°C, the outlet flue gas temperature is 185°C, and the flue gas flow rate is 2000m 3 / h, the flue gas enters the heat exchanger I for heat exchange and cooling, and the temperature is lowered to 130 °C; then the flue gas passes through the cyclone dust collector 3, the electrostatic collection and dust removal combined tar removal device 4, the activated carbon adsorption tower 5, and the dry desulfurization reactor 6. The dry dechlorination reactor 7 is processed to obtain a low-temperature preliminary purified gas, and the gas temperature is 65 °C;

[0056] Wherein, the desulfurizing agent used in the dry desulfurization reactor 6 is a mixture of 28.5g calcium oxide, 2.5g magnesium oxide, 5g iron oxide, 1.5g manganese oxide, 7.5g calcium carbonate, 2.5g cement and 8.3g silica sol (wherein SiO 2 30 wt.%) in a polyethylene beaker, grinding and mixing, and then dropwise add 30 mL of deionized water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com