Strontium titanate modified nickel cobalt lithium manganate positive electrode material and lithium ion battery containing same

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of positive electrodes, secondary batteries, battery electrodes, etc., can solve problems such as damage to electronic conduction paths, increased expansion of binders, and deterioration of cycle performance, so as to reduce production cost, reduce material internal stress, and improve the effect of production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

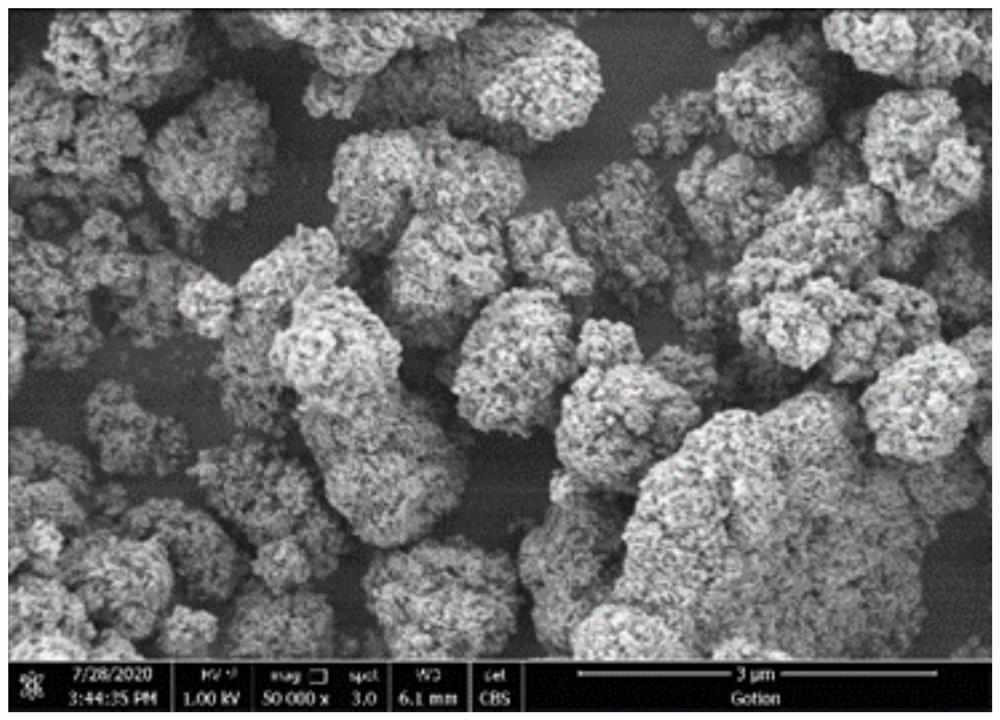

[0043] S1. According to the molar ratio of nickel, cobalt, and manganese elements = 7:1:2, mix soluble nickel sulfate, cobalt sulfate, and manganese sulfate with water, stir until completely dissolved, and obtain a mixture with a total concentration of metal ions of 1.0mol / L Solution A, then mixed solution A and concentration are 3.5mol / L sodium citrate complexing agent, concentration is 3.5mol / L sodium hydroxide solution precipitating agent, add in the reactor under nitrogen protection gas, adjust complexing agent and The flow rate of the precipitating agent is such that the pH in the reactor is maintained at 11.1-11.5 and the temperature is controlled at 50-55°C. The reaction is stirred for 8 hours and then aged for 10 hours. The nickel-cobalt-manganese precursor C is obtained after solid-liquid separation, washing and drying: Ni 0.7 co 0.1 mn 0.2 (OH) 2 .

[0044] S2, according to the general chemical formula Sr 0.98 TiO 3 : The stoichiometric ratio of each element in...

Embodiment 2

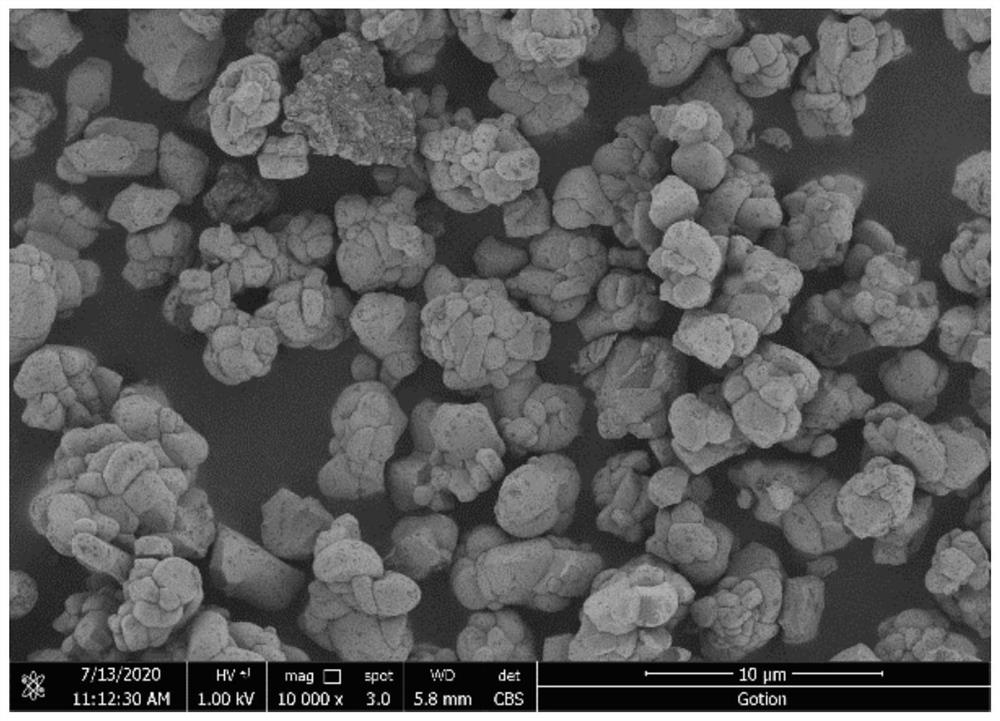

[0049] S1. According to the molar ratio of nickel, cobalt, and manganese elements = 6:2:2, mix soluble nickel sulfate, cobalt sulfate, and manganese sulfate with water, stir until completely dissolved, and obtain a mixture with a total concentration of metal ions of 1.5mol / L Solution A, then mixed solution A and concentration are 7.0mol / L sodium gluconate complexing agent, concentration is 7.0mol / L potassium hydroxide solution precipitating agent, add in the reactor under nitrogen protection gas, adjust complexing agent and The flow rate of the precipitating agent keeps the pH in the reactor at 10.2-11.4 and the temperature is controlled at 40-45°C. Stir the reaction for 36 hours and then continue aging for 36 hours. After solid-liquid separation, washing and drying, the nickel-cobalt-manganese precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 .

[0050] S2, according to the general chemical formula Sr 0.99 TiO 3 : The stoichiometric ratio of each element in 0.01La. Take chemically ...

Embodiment 3

[0054] S1. According to the molar ratio of nickel, cobalt, and manganese elements = 7:1:2, mix soluble nickel nitrate, cobalt nitrate, and manganese nitrate with water, stir until completely dissolved, and obtain a mixture with a total concentration of metal ions of 4.0mol / L Solution A, then the mixed solution A and the concentration of 3.5mol / L hydrazine hydrate complexing agent, the concentration of 3.5mol / L lithium hydroxide solution precipitation agent, add in the reaction kettle under the nitrogen protection gas, adjust the complexing agent and precipitation The flow rate of the agent is used to maintain the pH in the reactor at 11.8-12.0 and control the temperature at 60-70°C. Stir the reaction for 8 hours and then continue to age for 8 hours. After solid-liquid separation, washing and drying, the nickel-cobalt-manganese precursor Ni 0.7 co 0.1 mn 0.2 (OH) 2 .

[0055] S2, according to the general chemical formula Sr 0.98 TiO 3 : The stoichiometric ratio of each ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com