Polyimide composite aerogel, preparation method and application of polyimide composite aerogel as solar evaporator

A composite aerogel, polyimide technology, applied in the direction of solar thermal power generation, solar collectors, solar collectors in specific environments, etc. Solar energy conversion efficiency and other issues, to achieve high-efficiency solar evaporation rate and purification capacity, excellent hydrophilic performance and high temperature resistance, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 1.35g of polyamic acid and 1.485ml of triethylamine into 54ml of deionized water. After stirring and dissolving completely, pour the solution into a mold, place it in a four-way freezer for 30 minutes, and then transfer it to a vacuum After being processed in a freeze dryer for 72 hours, the sample was taken out and placed in a tube furnace for imidization reaction under the protection of nitrogen. The imidization condition is to heat the sample from room temperature to 80°C, 150°C and 250°C in sections at a rate of 8°C / min, and keep warm for 1 hour in each section to obtain polyimide airgel.

Embodiment 2

[0029] Step 1: Dissolve 0.12 g of tris powder in 100 ml of deionized water and adjust the pH of the solution to 4.5 with dilute hydrochloric acid. Then the solution was transferred to a three-necked flask, and 0.5 g of hydroxylated boron nitride, 0.2 g of dopamine hydrochloride and 0.12 g of ammonium persulfate were added thereto according to the mass ratio. After the above mixed solution was uniformly stirred by ultrasonic, it was stirred and reacted in a water bath at 60°C for 10 hours, then filtered and washed with deionized water, and dried at 80°C for 10 hours to obtain dopamine-modified boron nitride.

[0030] Step 2: Add 1.08g of polyamic acid and 1.485ml of triethylamine to 54ml of dopamine-modified boron nitride dispersion with a concentration of 5mg / ml, wherein the mass of polyamic acid and dopamine-modified boron nitride The ratio is 80:20.

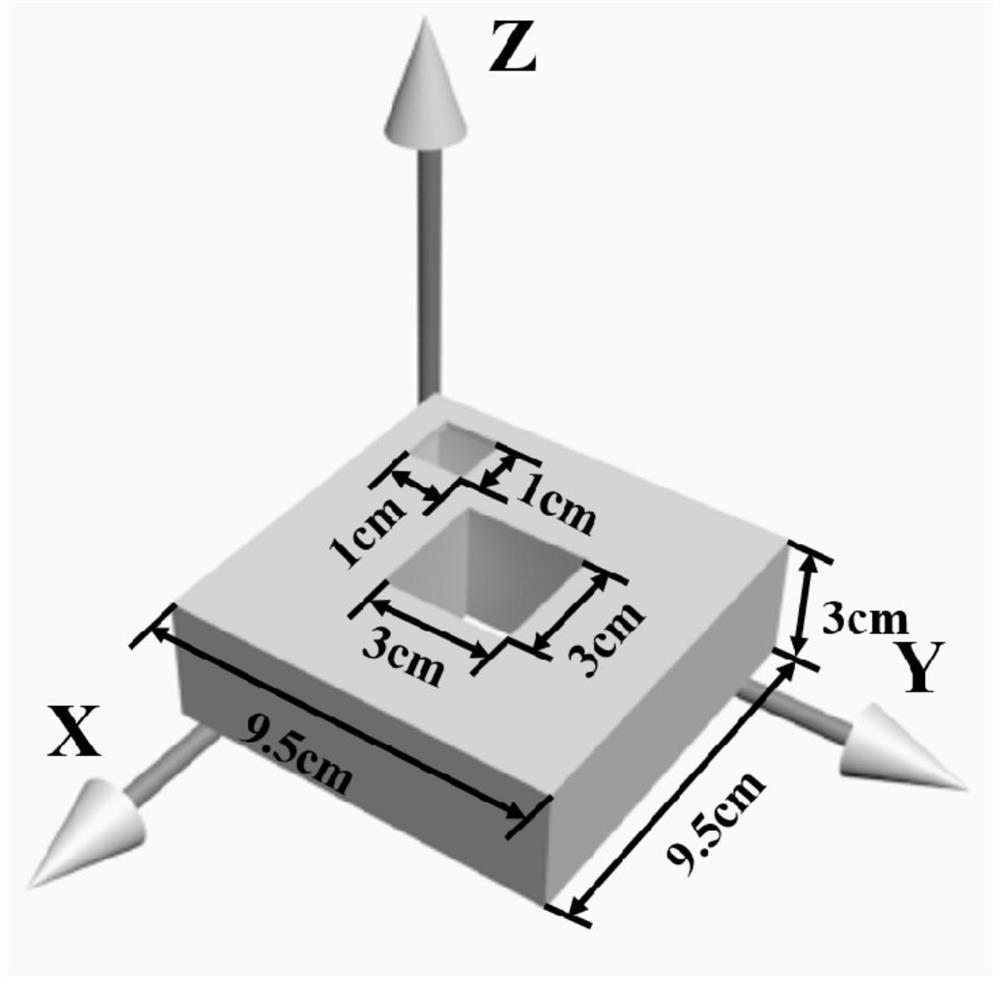

[0031] After stirring and dissolving completely, pour the solution into the mold, place it in a four-directional freezer for...

Embodiment 3

[0033] Step 1: Dissolve 0.12 g of tris powder in 100 ml of deionized water and adjust the pH of the solution to 4.5 with dilute hydrochloric acid. Then the solution was transferred to a three-necked flask, and 0.5 g of hydroxylated boron nitride, 0.2 g of dopamine hydrochloride and 0.12 g of ammonium persulfate were added thereto according to the mass ratio. After the above mixed solution was uniformly stirred by ultrasonic, it was stirred and reacted in a water bath at 60°C for 10 hours, then filtered and washed with deionized water, and dried at 80°C for 10 hours to obtain dopamine-modified boron nitride.

[0034] Step 2: Add 1.08g of polyamic acid into a beaker containing 40.5ml of dopamine-modified boron nitride dispersion with a concentration of 5mg / ml and 13.5ml of hydroxylated carbon nanotube dispersion with a concentration of 5mg / ml. And 1.485 ml of triethylamine was added thereto and stirred. Wherein, the mass ratio of polyamic acid, dopamine-modified boron nitride a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com