Catalyst for selective catalytic reduction denitration and preparation method thereof

A technology of catalyst and reduction method, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of increased energy consumption, decreased catalyst activity, and decreased boiler efficiency, etc. problem, to achieve the effect of improving efficiency, efficient adsorption, and enhancing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

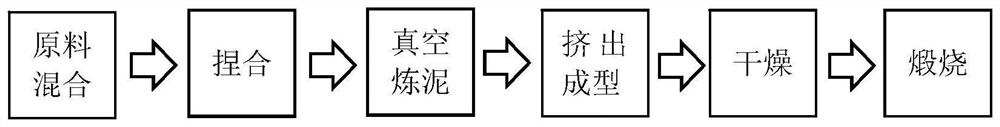

Method used

Image

Examples

Embodiment 1

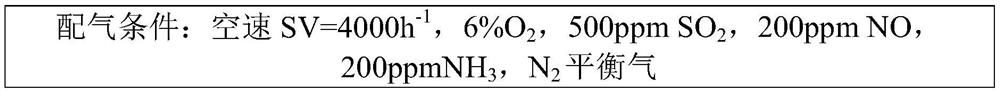

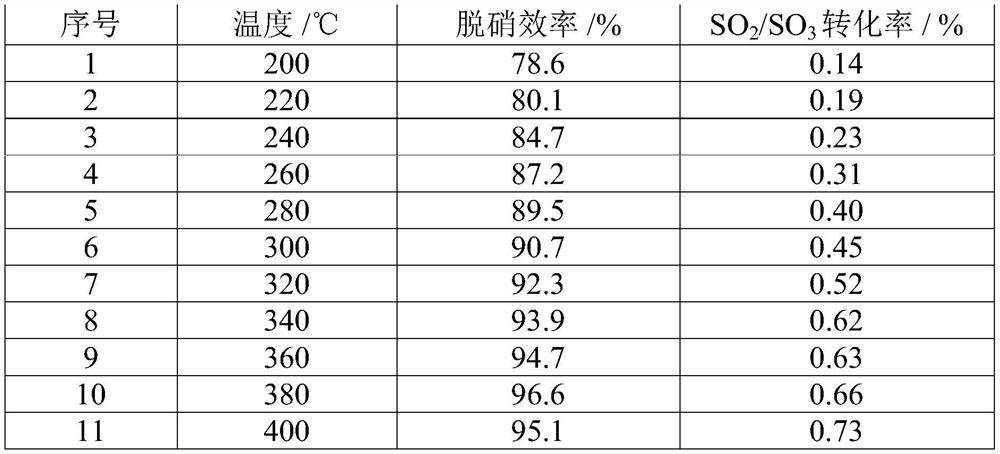

[0045] According to 1.5 parts of ammonium metavanadate, 17 parts of ammonium paratungstate, 1.3 parts of calcium silicate, 4.5 parts of barium sulfate, 15 parts of cerium carbonate, 20 parts of manganese carbonate, 145 parts of titanium dioxide, 8 parts of glass fiber, 1.5 parts of hardwood pulp, and 6 parts of ammonia water parts, 15 parts of acetic acid, 25 parts of oxalic acid, 1.3 parts of ethanolamine, 1.6 parts of lactic acid, 1.5 parts of carboxymethyl cellulose, 0.5 parts of stearic acid and 1.1 parts of ethylene oxide to prepare the honeycomb catalyst. The performance of the performance test on the bench is shown in Table 1, and Table 1 shows the performance test results of the modified catalyst prepared in Example 1 at different temperatures.

[0046] Table 1

[0047]

[0048]

[0049] It can be seen that the modified denitration catalyst has good denitration activity and low SO 2 / SO 3 Conversion rate, satisfying SO 2 / SO 3 The conversion rate is not highe...

Embodiment 2

[0051] A preparation method for selective catalytic reduction method denitration catalyst, comprising the following steps:

[0052] S1. Weigh 130 parts of titanium dioxide by weight, add 0.2 parts of stearic acid and 1.3 parts of lactic acid with a mass concentration of 50%, and knead for 30 minutes through a dry powder mixer, and stir and mix evenly to obtain a mixed raw material .

[0053] S2. Add 5 parts of ammonia water and deionized water with a mass concentration of 15% to the mixture obtained in S1, and add 5 parts of glass fiber and 1 part of hardwood pulp, and stir for about 80 minutes to obtain a uniform and stable mixture;

[0054] S3. Weigh 20 parts of oxalic acid and add it to deionized water to form a 2mol / L oxalic acid solution, heat the oxalic acid solution to 85°C, add 1 part of ammonium metavanadate, 15 parts of ammonium paratungstate and 1.2 parts of ethanolamine to the hot oxalic acid solution solution, keep the temperature of the solution at 85°C and stir...

Embodiment 3

[0061] A preparation method for selective catalytic reduction method denitration catalyst, comprising the following steps:

[0062] S1. Weigh 140 parts of titanium dioxide by weight, add 0.3 parts of stearic acid and 1.5 parts of lactic acid with a mass concentration of 50%, and knead for 40 minutes through a dry powder mixer, and stir and mix it evenly to obtain a mixed raw material .

[0063] S2. Add 5 parts of ammonia water and deionized water with a mass concentration of 15% to the mixture obtained in S1, and add 6 parts of glass fiber and 1.2 parts of hardwood pulp, and stir for 92 minutes to obtain a uniform and stable mixture;

[0064] S3. Weigh 21 parts of oxalic acid and add it to deionized water to form a 2mol / L oxalic acid solution, heat the oxalic acid solution to 86°C, add 1.5 parts of ammonium metavanadate, 17 parts of ammonium paratungstate and 1.3 parts of ethanolamine to the hot oxalic acid solution Solution, keep the temperature of the solution at 86°C and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com