Biodegradable composite modified film bag particle material and preparation method thereof

A technology of composite modification and biodegradation, which is applied in the field of composite modified film/bag particle materials and its preparation, can solve the problems that degradable film materials or particle materials cannot meet the performance at the same time, and achieve good biodegradability, good resistance Water-based, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

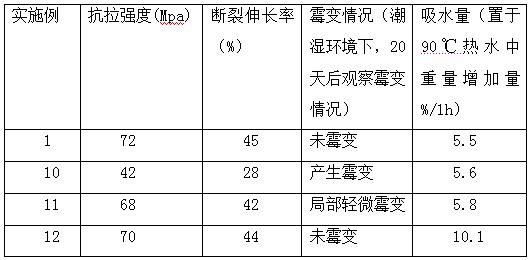

Examples

Embodiment 1

[0134] A biodegradable composite modified film / bag particle material, made of the following raw materials in parts by weight: 80 parts of oxidized modified high amylose corn starch, 6.5 parts of 1-ethyl-3 methylimidazole acetate, porol 3.5 parts of sham, 4 parts of corn distiller's grain concentrated dry powder, 4 parts of coconut shell powder, 3 parts of combination modifier, 2.4 parts of poly 3-hydroxybutyrate (PHB), poly(3-hydroxybutyrate-co- 3-hydroxyhexanoate) PHBHHx 5.6-parts, polybutylene adipate terephthalate (PBAT) 12 parts, BASF's epoxy-functional ADR chain extender 1 part, maleic anhydride 0.7 parts, polyoxygen 0.8 parts of ethylene (PEO), 4.5 parts of modified nano-carbon fibers, 20 parts of nano-calcium carbonate, and 10 parts of nano-zinc oxide; its preparation method comprises the following steps:

[0135] ① Weighing according to the weight ratio: 80 parts of oxidized modified high-amylose corn starch, 6.5 parts of 1-ethyl-3 methylimidazole acetate, and 3.5 part...

Embodiment 2

[0141] A biodegradable composite modified film / bag particle material, made of the following raw materials in parts by weight: 80 parts of oxidized modified high-amylose wheat starch, 5 parts of 1-ethyl-3 methylimidazole acetate, epoxy 5 parts of soybean oil, 5 parts of betel nut shell powder, 3 parts of concentrated dry wheat distiller's grain powder, 3 parts of combination modifier, 2.4 parts of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) PHBV, poly( 3-hydroxybutyrate-co-4-hydroxybutyrate) P34HB 5.6 parts, polybutylene adipate terephthalate (PBAT) 12 parts, BASF's epoxy functionalized ADR chain extender 1 part, 0.7 part of maleic anhydride, 0.8 part of polyoxyethylene (PEO), 5 parts of modified nano-carbon fibers, 18 parts of nano-calcium carbonate, 12 parts of nano-zinc oxide; its preparation method comprises the following steps:

[0142] ① Weighing according to the proportion by weight: 80 parts of oxidized modified high-amylose wheat starch, 5 parts of 1-ethyl-3 methylimi...

Embodiment 3

[0149] A biodegradable composite modified film / bag particle material, made of the following raw materials in parts by weight: 80 parts of oxidized modified high linear potato starch, 6 parts of lecithin, 4 parts of poloxamer, concentrated dry powder of sugarcane distiller's grains 4 parts, olive stone powder 4 parts, combined modifier 3 parts, poly(3-hydroxybutyrate-co-4-hydroxybutyrate) P34HB 2.4 parts, poly(3-hydroxybutyrate-co-3 -Hydroxycaproic acid ester) 5.6 parts of PHBHHx, 12 parts of polybutylene adipate terephthalate (PBAT), 1 part of BASF's epoxy functionalized ADR chain extender, 0.6 parts of maleic anhydride, polyoxyethylene ( 0.9 part of PEO), 6 parts of modified nano-carbon fiber, 19.5 parts of nano-calcium carbonate, 10 parts of nano-zinc oxide, 0.5 part of multi-walled carbon nanotube; its preparation method comprises the following steps:

[0150] ① Weigh according to the weight ratio: 80 parts of oxidized modified high linear potato starch, 6 parts of lecithin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com