Nitrogen and sulfur co-doped carbon quantum dot as well as preparation method and application thereof

A technology of nitrogen-sulfur co-doping and carbon quantum dots, applied in chemical instruments and methods, measuring devices, nanotechnology for materials and surface science, etc., can solve complex sample preparation and processing processes, expensive large-scale instruments and equipment, Unable to achieve rapid detection and other problems, to achieve the effect of simple and easy-to-control preparation method, significant reproducibility and stability, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of nitrogen-sulfur co-doped carbon quantum dots, the method comprising the following steps:

[0045] (1) Ammonium citrate and sodium thiosulfate are added to water, and ultrasonically mixed to obtain a mixed solution; the mass ratio of ammonium citrate to sodium thiosulfate is (0.45-0.75):(0.30-0.50).

[0046] (2) Put the mixed solution in a reaction kettle, and react at a constant temperature; the temperature of the constant temperature reaction is 140-180° C., and the time is 4-6 hours.

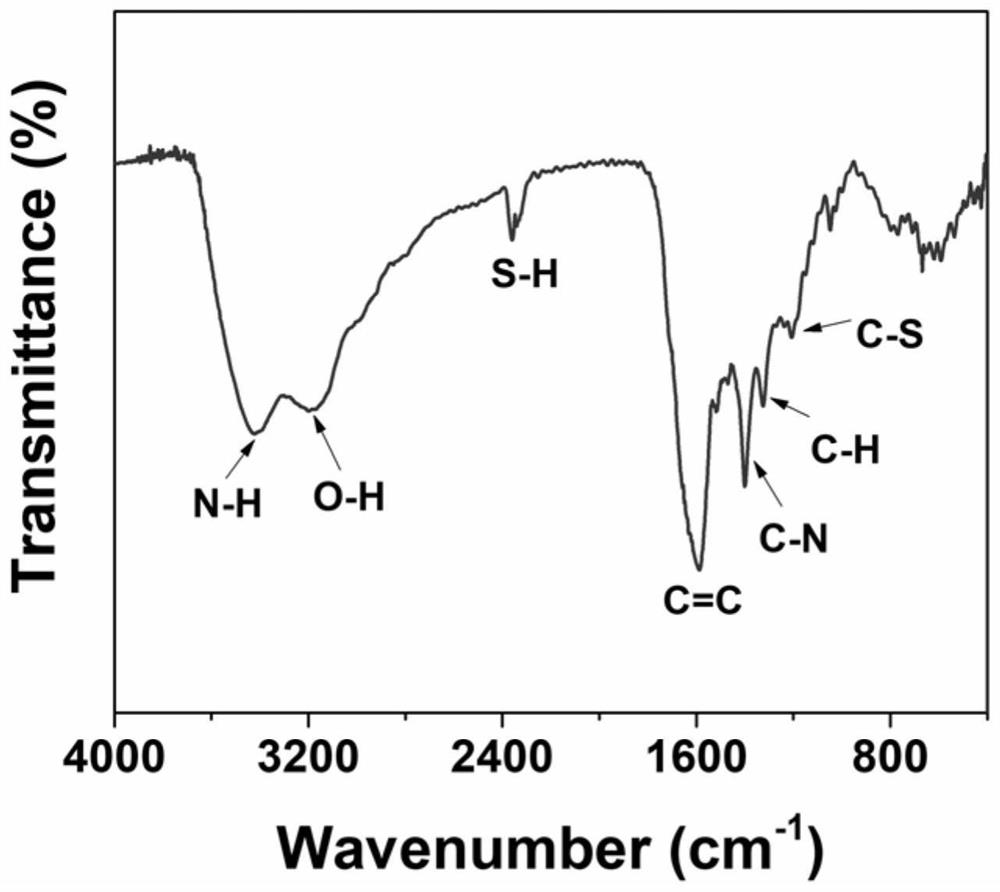

[0047] (3) After the reaction is over, the reaction solution is naturally cooled to room temperature, and the reaction solution is poured into a dialysis bag for dialysis to obtain a pure aqueous solution of nitrogen-sulfur co-doped carbon quantum dots, which is then freeze-dried to obtain nitrogen-sulfur co-doped carbon quantum dots. Quantum dots, the size distribution of the carbon quantum dots is 1.5-5.0nm, and the surface is rich in -NH 2 , -OH and -SH funct...

Embodiment 1

[0053] A preparation method of nitrogen-sulfur co-doped carbon quantum dots, the method comprising the following steps:

[0054] (1) Dissolve 0.60 g of ammonium citrate and 0.40 g of sodium thiosulfate in 25 mL of deionized water, and ultrasonicate for 5 minutes to obtain a mixed solution;

[0055] (2) Place the mixed solution described in step (1) in a high-pressure reactor, and react at 160° C. for 5 hours;

[0056] (3) After the reaction in step (2) ends, the reaction solution is naturally cooled to room temperature, and the reaction solution is poured into a dialysis bag with a molecular weight cut-off of 100 Da, and dialyzed for 24 hours to obtain an aqueous solution of pure nitrogen-sulfur co-doped carbon quantum dots, Nitrogen-sulfur co-doped carbon quantum dots were obtained after freeze-drying.

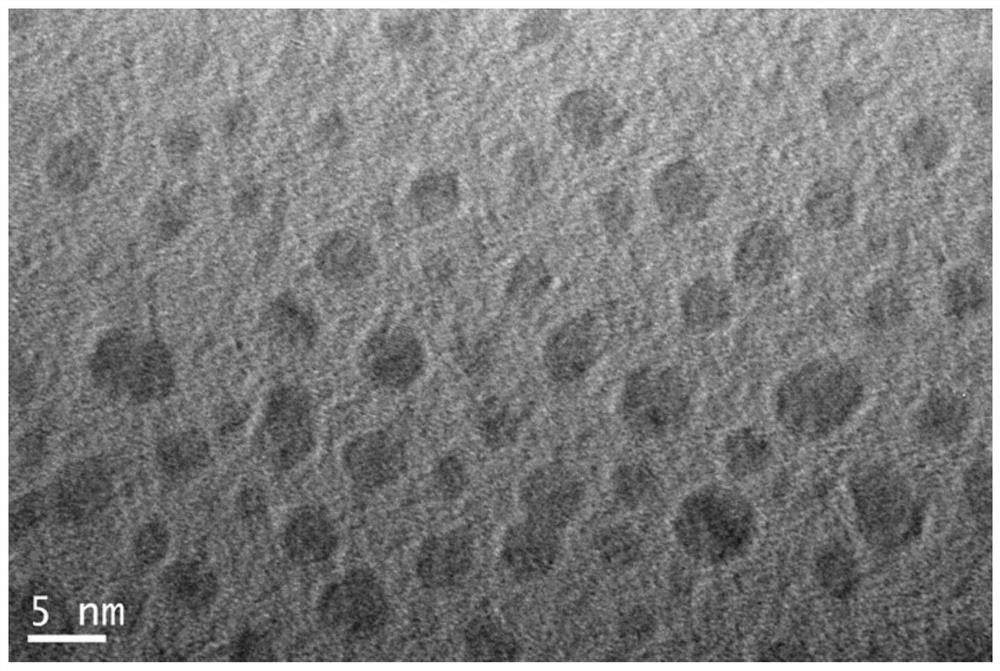

[0057] Depend on figure 1 It can be seen that the nitrogen-sulfur co-doped carbon quantum dots have good dispersion and narrow size distribution, with an average size of ab...

Embodiment 2

[0059] A preparation method of nitrogen-sulfur co-doped carbon quantum dots, the method comprising the following steps:

[0060] (1) Dissolve 0.45g of ammonium citrate and 0.30g of sodium thiosulfate in 25mL of deionized water, and ultrasonicate for 5min to obtain a mixed solution;

[0061] (2) Place the mixed solution described in step (1) in a high-pressure reactor, and react at 180° C. for 4 hours;

[0062] (3) After the reaction in step (2) ends, the reaction solution is naturally cooled to room temperature, and the reaction solution is poured into a dialysis bag with a molecular weight cut-off of 100 Da, and dialyzed for 24 hours to obtain an aqueous solution of pure nitrogen-sulfur co-doped carbon quantum dots, Nitrogen-sulfur co-doped carbon quantum dots were obtained after freeze-drying.

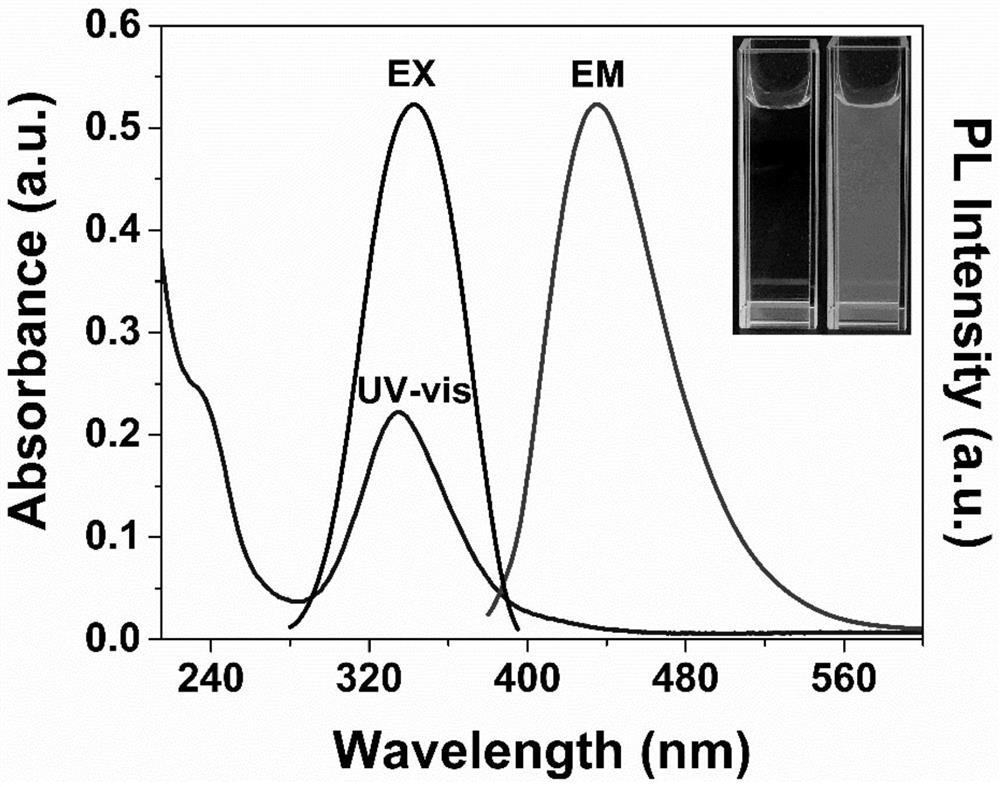

[0063] The nitrogen-sulfur co-doped carbon quantum dots have a size distribution of 1.5-5.0nm and abundant -NH on the surface 2 , -OH, -SH and other functional groups, the maximum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com