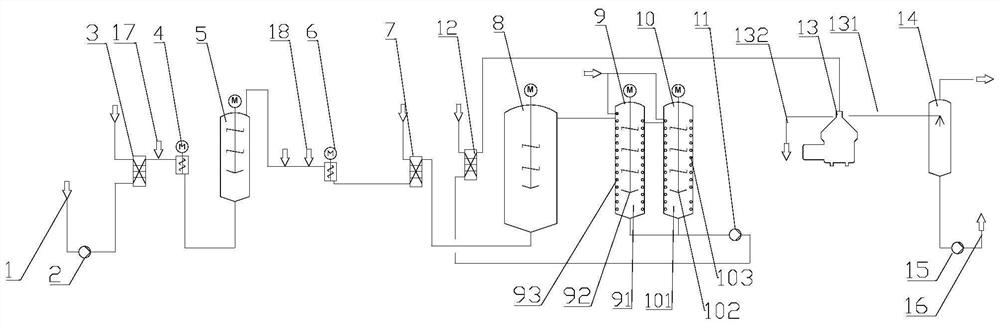

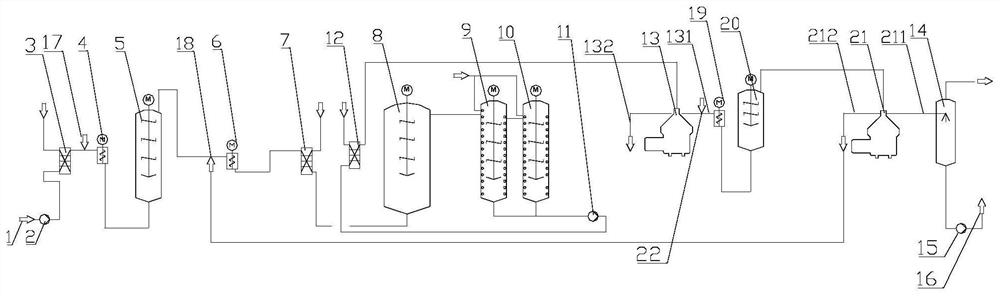

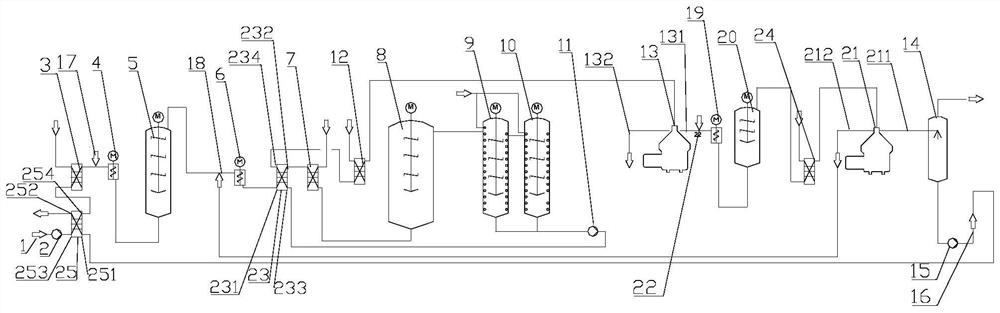

Combined degumming and dewaxing process and refining process of wax-containing edible vegetable oil

An edible vegetable oil, degumming and dewaxing technology, applied in the field of combined degumming and dewaxing process and refining process, can solve the problems of high wax viscosity, high consumption, low hardness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0192] Raw materials: leached bran oil (hair rice oil), acid value 11.2mgKOH / g, impurity content 10.3%, wax content: 3.2%; phosphorus content 540ppm, water content 0.131%; oryzanol 1.49%; VE and sterols: 2.43%

[0193] The crude bran oil at room temperature is passed into the crude oil inlet pipe, heated to 58°C by the first heater, and a 50wt% citric acid aqueous solution is added through the acid solution inlet until the citric acid accounts for 0.25% of the crude oil weight, and mixed by the first mixer Enter the acid reaction tank, the stirring speed is 60 rpm, and the reaction time is 30 minutes. After the reaction, the reaction rate of non-hydratable phospholipids into hydratable phospholipids is >99.5%; add hot water (75°C) from the first water inlet, and the amount of water added Soft water with 2.5 times the weight content of phospholipids is mixed by the second mixer, cooled to 25°C by the first cooler, and the water-oil mixture is passed into the hydration reaction t...

Embodiment 2

[0198] Raw materials: leached corn germ oil, acid value 5.8mgKOH / g, wax content: 380ppm; moisture content 0.75%, phosphorus content 320ppm; oryzanol 780ppm and VE sterol content higher than 14700ppm.

[0199] The raw corn germ oil at normal temperature is passed into the crude oil inlet pipe, heated to 65°C by the first heater, and the concentration of 50wt% citric acid aqueous solution is added through the acid solution inlet until the citric acid accounts for 0.18% of the crude oil weight, and then passed through the first mixer After mixing, enter the acid reaction tank, the stirring speed is 60 rpm, and the reaction time is 30 minutes. After the reaction, the reaction rate of non-hydratable phospholipids into hydratable phospholipids is >99.5%; add hot water (75 ° C) from the first water inlet, The amount of soft water added is 2.5 times the weight content of phospholipids, mixed by the second mixer, cooled to 25°C by the first cooler, and the water-oil mixture is passed in...

Embodiment 3

[0209] Raw materials: leached sunflower oil, acid value 2.5mgKOH / g, wax content: 900ppm; moisture content 0.75%, phosphorus content 850ppm.

[0210] The normal temperature crude sunflower oil is passed into the crude oil inlet pipe, heated to 60°C by the first heater, and the concentration of 50wt% citric acid aqueous solution is added through the acid liquid inlet until the citric acid accounts for 0.15% of the crude oil weight, and then passed through the first mixer After mixing, enter the acid reaction tank, the stirring speed is 60 rpm, and the reaction time is 30 minutes. After the reaction, the reaction rate of non-hydratable phospholipids into hydratable phospholipids is >99.5%; add hot water (75 ° C) from the first water inlet, The amount of soft water added is 2.2 times the weight content of phospholipids, mixed by the second mixer, cooled to 25°C by the first cooler, and the water-oil mixture is passed into the hydration reaction tank. The hydration reaction tank ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| smoke point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com