Core-shell type molecular sieve containing phosphorus and metal and synthesis method thereof

A synthesis method and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, molecular cracking to hydrocarbons, etc., can solve problems such as inability to obtain application effects, and achieve low coke selectivity, high heavy oil conversion activity, and high propylene yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

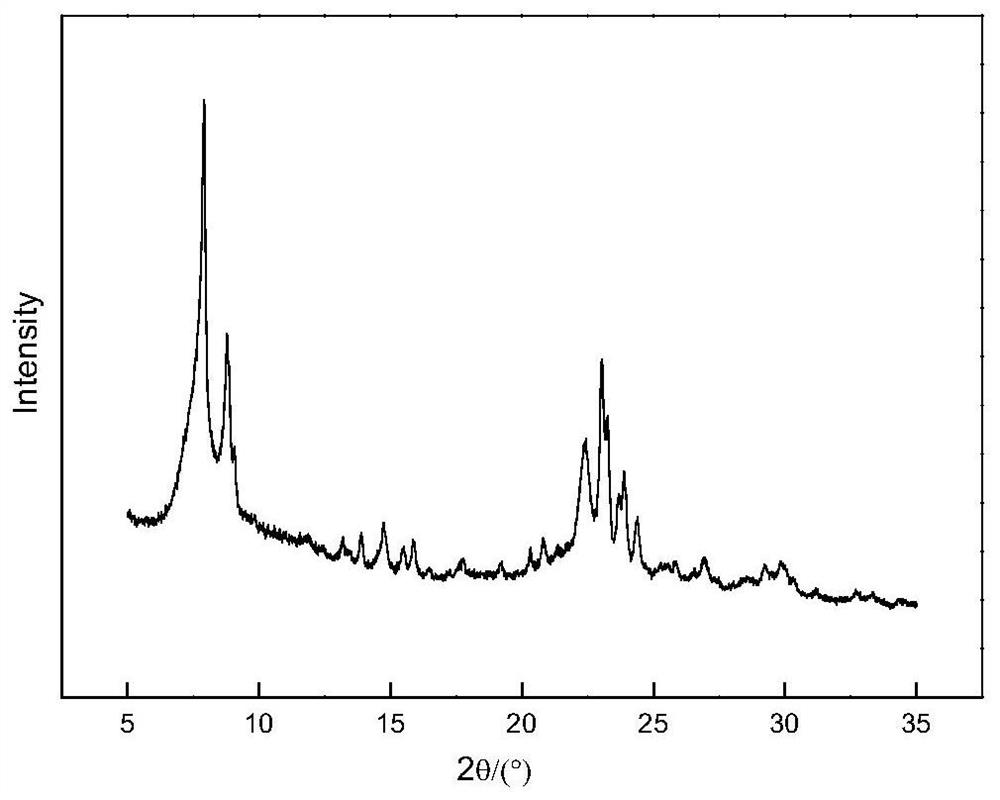

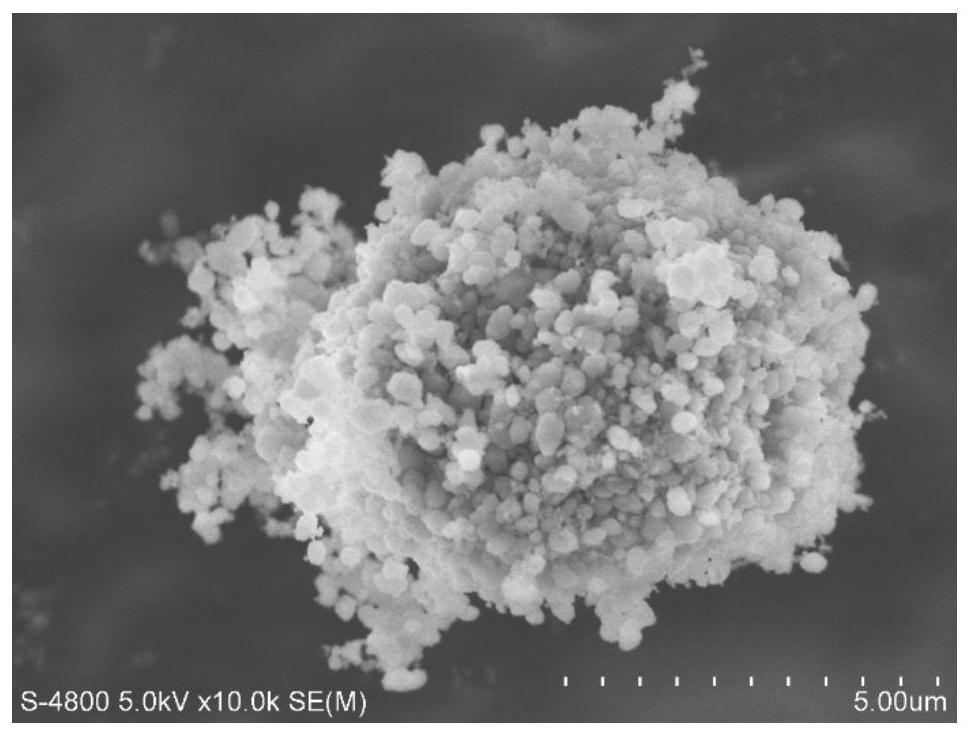

Image

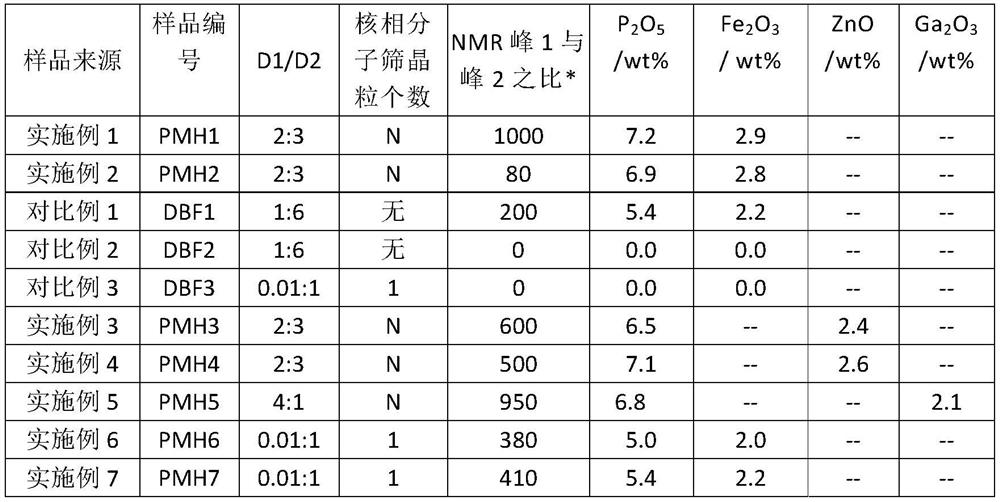

Examples

preparation example Construction

[0061] According to the synthesis method of the phosphorus-containing and metal-containing core-shell molecular sieve provided by the present invention, preferably, the synthesis method of the hydrogen-type core-shell molecular sieve comprises the following steps:

[0062] (A) making ZSM-5 molecular sieve (raw material) contact with surfactant solution to obtain ZSM-5 molecular sieve I;

[0063] (B) make ZSM-5 molecular sieve I contact with the slurry containing β molecular sieve, obtain the ZSM-5 molecular sieve containing β molecular sieve and denote as ZSM-5 molecular sieve II;

[0064] (C) form a mixture of silicon source, aluminum source, template agent (represented by R), and deionized water, and crystallize at 50°C-300°C for 4-100h to perform the first crystallization to obtain synthetic solution III;

[0065] (D) Mix the ZSM-5 molecular sieve II with the synthetic liquid III for the second crystallization, the crystallization temperature of the second crystallization i...

Embodiment approach

[0067] According to the synthesis method of phosphorus-containing and metal-containing core-shell molecular sieves provided by the present invention, the method of contacting described in step (A), an embodiment, includes: adding ZSM-5 molecular sieve (raw material) to surface active Treat in the surfactant solution for at least 0.5 hours such as 0.5-48h, obtain ZSM-5 molecular sieve I after filtering and drying; wherein the weight percent concentration of the surfactant in the surfactant solution is 0.05%-50%, preferably 0.1% -30% eg 0.1%-5%.

[0068] According to the method for synthesizing a phosphorus- and metal-containing core-shell molecular sieve provided by the present invention, in one embodiment, the surfactant solution further contains a salt, and the salt is used to separate or disperse the surfactant For example, the salt is one or more of sodium chloride, potassium chloride, ammonium chloride, ammonium nitrate; the concentration of the salt in the surfactant solu...

Embodiment 1

[0094] (1) At room temperature (25°C), the ZSM-5 molecular sieve (H-type ZSM-5, silicon-aluminum ratio 30, average grain size 1.2 μm) used as the core phase is the average grain size of the grains agglomerated 15 μm, crystallinity 93.0%) 10.0 g was added to 100.0 g methyl methacrylate with a mass percentage of 0.2% in an aqueous solution containing methyl methacrylate and sodium chloride (sodium chloride mass concentration 5.0%) and stirred for 1 h, Filter and dry under air atmosphere at 50°C to obtain ZSM-5 molecular sieve I;

[0095] (2) ZSM-5 molecular sieve I is dropped into beta molecular sieve suspension liquid (the suspension liquid that H beta molecular sieve and water form, and beta molecular sieve weight percent concentration is 0.3% by weight in suspension liquid; Beta molecular sieve average grain size is 200nm , the silicon-aluminum ratio is 30, the crystallinity is 89.0%, and the β molecular sieve particle is a single grain particle), the mass ratio of the ZSM-5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com