Method for carrying out spark plasma diffusion bonding on silicon carbide ceramics by adopting refractory high-entropy alloy interlayer

A technology of discharge plasma and silicon carbide ceramics, which is applied in the direction of welding equipment, electric heating devices, welding media, etc., can solve the problems of weakening the strength of joints and reducing the reliability of joints in service, and achieves the relief of residual stress, high engineering practical value, and improvement of joints. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

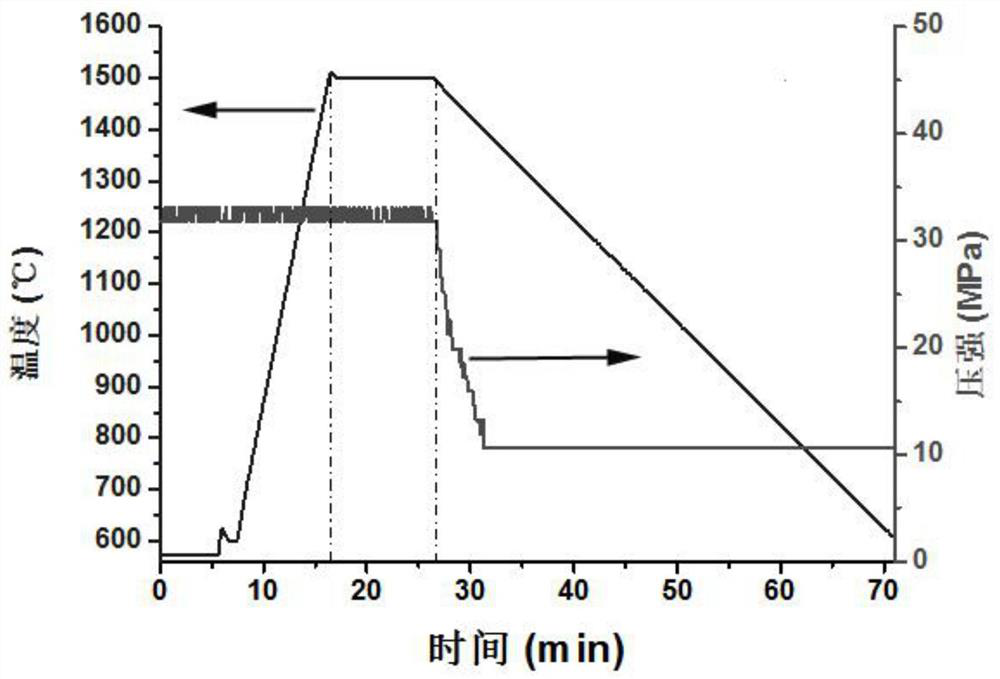

[0036] In this embodiment, a method of using refractory high-entropy alloy interlayer discharge plasma diffusion to connect silicon carbide ceramics is as follows:

[0037] 1. Preparation of refractory high-entropy alloy

[0038] Preparation before smelting: Weigh the raw materials by molar ratio, 14.2 at.% of tantalum particles (Ta) with a purity of 99.95%, 28.6 at.% of crystalline hafnium particles (Hf) with a purity of ≥99.95%, and 28.6 at.% of crystalline zirconium particles with a purity of ≥99.95% ( Zr) 28.6at.% and titanium particles (Ti) 28.6at.% with a purity of 99.99%, a total of 30g;

[0039] Sample loading and atmosphere purification: Put the weighed metal raw materials into the water-cooled crucible of the vacuum melting furnace in order of melting point from low to high, close the furnace door, and vacuumize. When the vacuum degree reaches 3 to 5×10 -3 Pa filled with high-purity argon to 0.05MPa;

[0040] Alloy smelting: hang the arc gun at 1-3mm directly above...

Embodiment 2

[0052] In this embodiment, a method of using refractory high-entropy alloy interlayer discharge plasma diffusion to connect silicon carbide ceramics is as follows:

[0053] 1. Preparation of refractory high-entropy alloy

[0054] Preparation before smelting: Weigh the raw materials by molar ratio, 14.2 at.% of tantalum particles (Ta) with a purity of 99.95%, 28.6 at.% of crystalline hafnium particles (Hf) with a purity of ≥99.95%, and 28.6 at.% of crystalline zirconium particles with a purity of ≥99.95% ( Zr) 28.6at.% and titanium particles (Ti) 28.6at.% with a purity of 99.99%, a total of 30g;

[0055] Sample loading and atmosphere purification: Put the weighed metal raw materials into the water-cooled crucible of the vacuum melting furnace in order of melting point from low to high, close the furnace door, and vacuumize. When the vacuum degree reaches 3 to 5×10 -3 Pa filled with high-purity argon to 0.05MPa;

[0056] Alloy smelting: hang the arc gun at 1-3mm directly above...

Embodiment 3

[0067] In this embodiment, a method of using refractory high-entropy alloy interlayer discharge plasma diffusion to connect silicon carbide ceramics is as follows:

[0068] 1. Preparation of refractory high-entropy alloy

[0069] Preparation before smelting: Weigh the raw materials by molar ratio, 14.2 at.% of tantalum particles (Ta) with a purity of 99.95%, 28.6 at.% of crystalline hafnium particles (Hf) with a purity of ≥99.95%, and 28.6 at.% of crystalline zirconium particles with a purity of ≥99.95% ( Zr) 28.6at.% and titanium particles (Ti) 28.6at.% with a purity of 99.99%, a total of 30g;

[0070] Sample loading and atmosphere purification: Put the weighed metal raw materials into the water-cooled crucible of the vacuum melting furnace in order of melting point from low to high, close the furnace door, and vacuumize. When the vacuum degree reaches 3 to 5×10 -3 Pa filled with high-purity argon to 0.05MPa;

[0071] Alloy smelting: hang the arc gun at 1-3mm directly above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com