Single-component second-order reaction waterborne epoxy sealing emulsion for bridge deck concrete

A second-order reaction, water-based epoxy technology, applied in the field of coatings, can solve the problems of long solidification time of film-forming substances, interface incompatibility, cracking and peeling, etc., and achieve the effect of good construction, not easy to precipitate, and strong waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

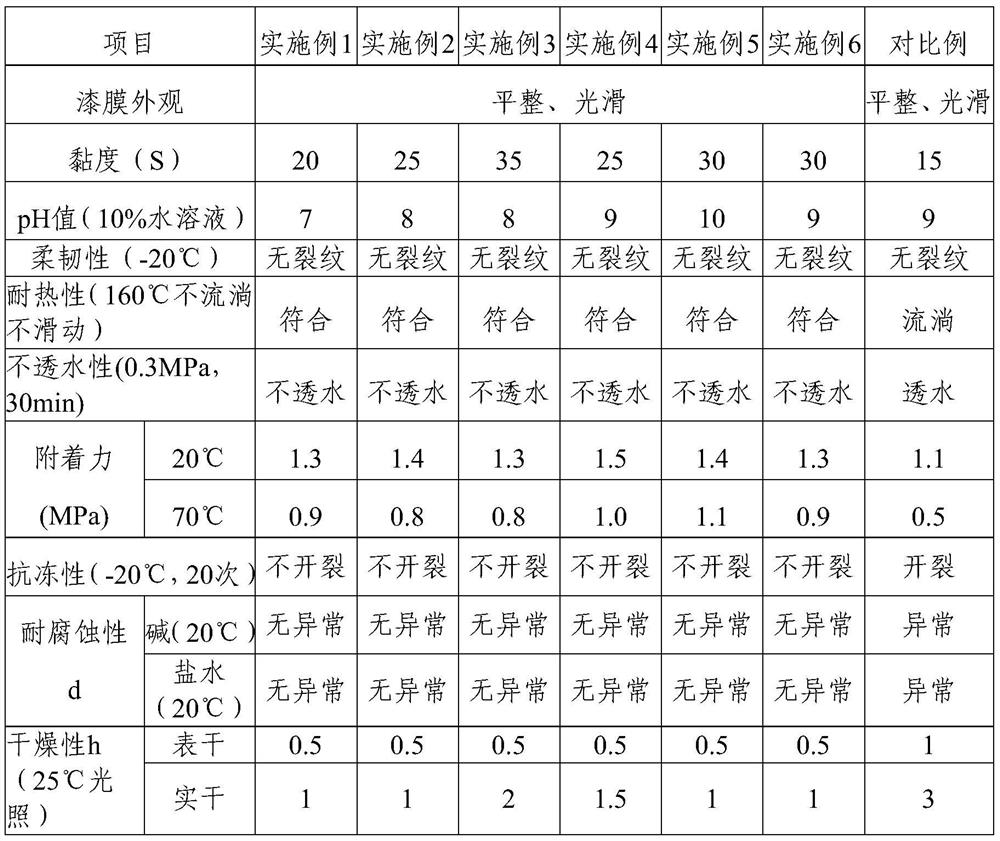

Examples

Embodiment 1

[0021] 2 parts of water-based amino mixed ether resin, 25 parts of E20 epoxy resin, 3 parts of E44 epoxy resin, 15 parts of polysiloxane modified epoxy resin, 1 part of buffer solution acetic acid, 10 parts of resin emulsifier dimer acid, curing Dicyandiamide 2 parts, rheological agent polyethylene wax 3 parts, toughening agent neopentyl glycol diglycidyl ether 5 parts, borane coupling agent 1 part, catalyst cyclodextrin 0.5 parts, film-forming aid propylene glycol 0.3 part of methyl ether, 0.2 part of BYK333 leveling agent, 0.2 part of TEGO-245 wetting agent, 0.1 part of defoamer, 13 parts of water.

Embodiment 2

[0023] 8 parts of water-based amino mixed ether resin, 30 parts of E20 epoxy resin, 8 parts of E44 epoxy resin, 20 parts of polysiloxane modified epoxy resin, 8 parts of buffer solution phosphoric acid, 15 parts of resin emulsifier dimer acid, curing 8 parts of dicyandiamide as agent, 3 parts of rheological agent polyamide wax, 10 parts of toughening agent 1,4-butanediol diglycidyl ether, 2 parts of borane coupling agent, 1 part of catalyst cyclodextrin, film-forming Additives: 0.5 parts of dipropylene glycol butyl ether, 0.3 parts of BYK333 leveling agent, 0.4 parts of TEGO-500 wetting agent, 0.5 parts of defoaming agent, and 27 parts of water.

Embodiment 3

[0025] 2 parts of water-based amino mixed ether resin, 30 parts of E20 epoxy resin, 3 parts of E44 epoxy resin, 20 parts of polysiloxane modified epoxy resin, 8 parts of buffer solution phosphoric acid, 15 parts of resin emulsifier quaternary ammonium salt, 8 parts of curing agent ketimine, 1 part of rheological agent polymerized urea, 10 parts of toughening agent 1,6-hexanediol diglycidyl ether, 2 parts of titanate coupling agent, 1 part of catalyst crown ether, film forming Additives Dipropylene glycol butyl ether 0.5 parts, BYK333 leveling agent 0.2 parts, BYK346 wetting agent 0.4 parts, defoamer 0.5 parts, water 20 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com