Polyimide nanofiber membrane coated with cerium dioxide nanolayer on surface and preparation method of polyimide nanofiber membrane

A technology of nanofiber membrane and cerium oxide, which is applied in fiber type, fiber treatment, textile and paper making, etc. It can solve the problems of poor electrolyte wettability, high temperature, and low ion conductivity of batteries, and meets the requirements of process equipment and is easy to meet. Excellent high temperature resistance, the effect of uniform fiber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

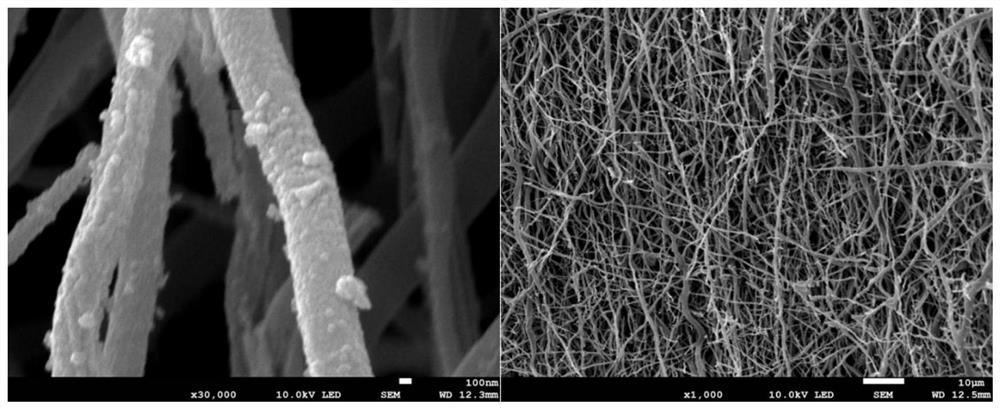

[0035] Prepare the PMDA / ODA system polyamic acid nanofiber membrane, obtain the polyimide nanofiber membrane after thermal imidization, first place it in 0.1mol / L potassium hydroxide solution for etching, add 7ml of glacial acetic acid, drop 10 drops Dilute ammonia water, then place in 1mol / L ceria precursor solution, add 5ml hydrogen peroxide solution, and finally undergo heat treatment to obtain polyimide / ceria composite nanofiber membrane. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N - in dimethylformamide (DMF) solvent, mechanically stirred, after ODA is all dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining the polyamic acid solution with moderate viscosity, after mechanically stirring for 2h, put The polyamic acid solution is put into a 20ml syringe, and the polyamic acid fiber film is prepared by electrospinning te...

Embodiment 2

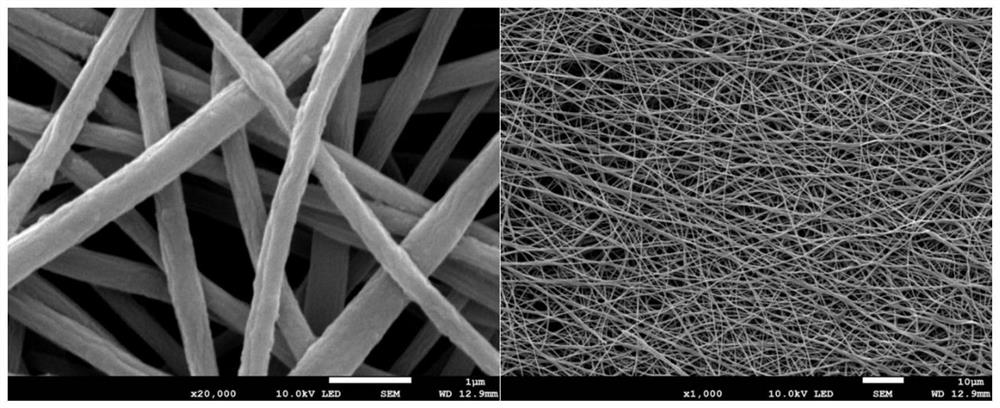

[0039] Prepare the PMDA / ODA system polyamic acid nanofiber membrane, obtain the polyimide nanofiber membrane after thermal imidization, first place it in 0.1mol / L potassium hydroxide solution for etching, add 7ml of glacial acetic acid, drop 10 drops Dilute ammonia water, then place in 1mol / L ceria precursor solution, add 5ml hydrogen peroxide solution, and finally undergo heat treatment to obtain polyimide / ceria composite nanofiber membrane. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N - in dimethylformamide (DMF) solvent, mechanically stirred, after ODA is all dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining the polyamic acid solution with moderate viscosity, after mechanically stirring for 2h, put The polyamic acid solution is put into a 20ml syringe, and the polyamic acid fiber film is prepared by electrospinning te...

Embodiment 3

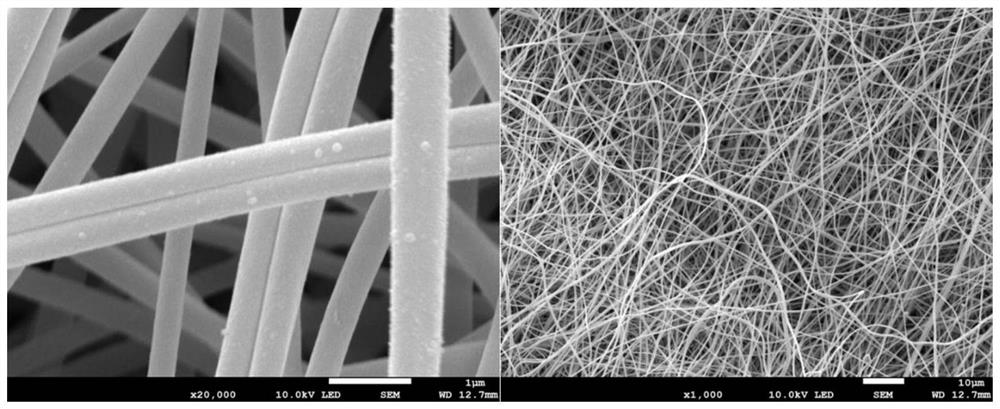

[0043] Prepare the PMDA / ODA system polyamic acid nanofiber membrane, obtain the polyimide nanofiber membrane after thermal imidization, first place it in 0.1mol / L potassium hydroxide solution for etching, add 7ml of glacial acetic acid, drop 10 drops Dilute ammonia water, then place in 1mol / L ceria precursor solution, add 5ml hydrogen peroxide solution, and finally undergo heat treatment to obtain polyimide / ceria composite nanofiber membrane. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N - in dimethylformamide (DMF) solvent, mechanically stirred, after ODA is all dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining the polyamic acid solution with moderate viscosity, after mechanically stirring for 2h, put The polyamic acid solution is put into a 20ml syringe, and the polyamic acid fiber film is prepared by electrospinning te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com