Slow-release feed additive for pigs and poultry, and preparation method and application of slow-release feed additive

A feed additive and slow-release technology, which is applied in the field of slow-release feed additives and their preparation, can solve the problems of complex process, inability to achieve targeted slow-release, etc., and achieves simple process, enhanced immunity and disease resistance, Effects without any side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

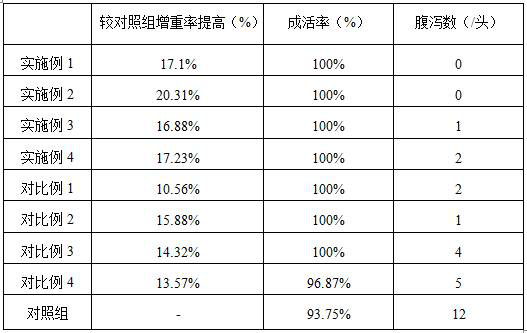

Examples

Embodiment 1

[0042] A method for preparing a slow-release feed additive for pigs and poultry, comprising preparing microencapsulated plant essential oil capsule core liquid, preparing microencapsulated plant essential oil coating liquid, preparing microencapsulated plant essential oil, preparing mixed acid, preparing Feed additives.

[0043] In the preparation of the microencapsulated plant essential oil capsule core liquid, the cinnamaldehyde, carvacrol and thymol are uniformly mixed according to the mass ratio of 1:3:0.5 to obtain the microencapsulated plant essential oil capsule core liquid.

[0044]In the preparation of the microencapsulated plant essential oil coating solution, 16 parts by mass of polyacrylic resin No. 1 (methacrylic acid: polyethylacrylate = 1:1), 16 parts by mass of gum arabic, and 0.04 parts by mass of anti-adhesive Magnesium stearate, 4 parts by mass of talcum powder, 1 part by mass of plasticizer (glycerin: polyglycerol fatty acid ester = 2:1), 0.5 parts by mass ...

Embodiment 2

[0051] A method for preparing a slow-release feed additive for pigs and poultry, comprising preparing microencapsulated plant essential oil capsule core liquid, preparing microencapsulated plant essential oil coating liquid, preparing microencapsulated plant essential oil, preparing mixed acid, preparing Feed additives.

[0052] In the preparation of the microencapsulated plant essential oil capsule core liquid, the cinnamaldehyde, carvacrol and thymol are uniformly mixed according to the mass ratio of 2:2:0.5 to obtain the microencapsulated plant essential oil capsule core liquid.

[0053] In the preparation of the microencapsulated plant essential oil coating solution, 16 parts by mass of polyacrylic resin No. 1 (methacrylic acid: polyethylacrylate = 1:1), 16 parts by mass of gum arabic, and 0.04 parts by mass of anti-adhesive Magnesium stearate, 4 parts by mass of talc, 1.5 parts of plasticizer (glycerin: polyglycerol fatty acid ester = 2:1), 0.4 parts by mass of polyvinylp...

Embodiment 3

[0060] A method for preparing a slow-release feed additive for pigs and poultry, comprising preparing microencapsulated plant essential oil capsule core liquid, preparing microencapsulated plant essential oil coating liquid, preparing microencapsulated plant essential oil, preparing mixed acid, preparing Feed additives.

[0061] In the preparation of the microencapsulated plant essential oil capsule core liquid, the cinnamaldehyde, carvacrol and thymol are uniformly mixed according to the mass ratio of 3:1:0.5 to obtain the microencapsulated plant essential oil capsule core liquid.

[0062] In the preparation of the microencapsulated plant essential oil coating solution, 16 parts by mass of polyacrylic resin No. 1 (methacrylic acid: polyethylacrylate = 1:1), 16 parts by mass of gum arabic, and 0.04 parts by mass of anti-adhesive Magnesium stearate, 4 parts by mass of talcum powder, 1.25 parts by mass of plasticizer (glycerin: polyglycerol fatty acid ester = 2:1), 0.5 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss rate | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com