Preparation method and application of phosphorus-doped molybdenum disulfide/porous carbon composite material

A technology of molybdenum disulfide and composite materials, applied in chemical instruments and methods, chemical/physical processes, hybrid capacitor electrodes, etc., can solve the problems of potential safety hazards in phosphorus source raw materials, increased active surface area, and fewer catalytic active sites , to achieve excellent electrolytic water hydrogen evolution catalytic activity, low cost, and high synthesis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

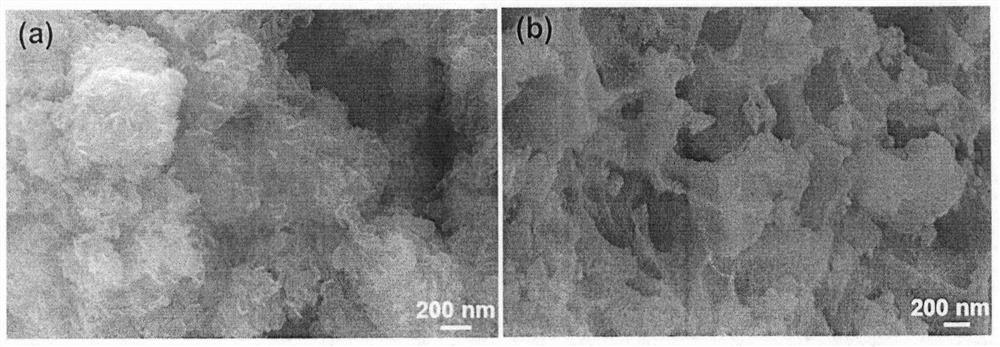

[0026] (1) Prepare porous carbon material with natural agar powder as carbon source and urea as nitrogen source; take 1g of agar powder, dissolve it in 20mL deionized water, heat it in a water bath at 90°C and keep stirring until it dissolves, then take Disperse 1g of potassium hydroxide and 1g of urea in the above solution, stir until dissolved; put it in an oven at 80°C for 7 hours; put the dried material in a tube furnace, 2 The temperature was raised to 750°C at a rate of 5°C / min in an atmosphere, kept for 2 hours and then slowly lowered to room temperature; the obtained powder was alternately washed several times with dilute hydrochloric acid and deionized water, and finally the carbon was dried at 100°C for 8 hours to prepare A nitrogen-doped porous carbon material was obtained; 6 mg of nitrogen-doped porous carbon material was stirred in 30 mL deionized water for 30 min; sodium molybdate and thioacetamide were dissolved in the above solution at a ratio of 1:6, and the mi...

Embodiment 2

[0034] (1) Prepare porous carbon material with natural agar powder as carbon source and urea as nitrogen source; take 1g of agar powder, dissolve it in 20mL deionized water, heat it in a water bath at 90°C and keep stirring until it dissolves, then take Disperse 1g of potassium hydroxide and 1g of urea in the above solution, stir until dissolved; put it in an oven at 80°C for 7 hours; put the dried material in a tube furnace, 2The temperature was raised to 750°C at a rate of 5°C / min in an atmosphere, kept for 2 hours and then slowly lowered to room temperature; the obtained powder was alternately washed several times with dilute hydrochloric acid and deionized water, and finally the carbon was dried at 100°C for 8 hours to prepare A nitrogen-doped porous carbon material was obtained; 6 mg of nitrogen-doped porous carbon material was stirred in 30 mL deionized water for 30 min; sodium molybdate and thioacetamide were dissolved in the above solution at a ratio of 1:6, and the mix...

Embodiment 3

[0037] (1) Prepare porous carbon material with natural agar powder as carbon source and urea as nitrogen source; take 1g of agar powder, dissolve it in 20mL deionized water, heat it in a water bath at 90°C and keep stirring until it dissolves, then take Disperse 1g of potassium hydroxide and 1g of urea in the above solution, stir until dissolved; put it in an oven at 80°C for 7 hours; put the dried material in a tube furnace, 2 The temperature was raised to 750°C at a rate of 5°C / min in an atmosphere, kept for 2 hours and then slowly lowered to room temperature; the obtained powder was alternately washed several times with dilute hydrochloric acid and deionized water, and finally the carbon was dried at 100°C for 8 hours to prepare A nitrogen-doped porous carbon material was obtained; 6 mg of nitrogen-doped porous carbon material was stirred in 30 mL deionized water for 30 min; sodium molybdate and thioacetamide were dissolved in the above solution at a ratio of 1:6, and the mi...

PUM

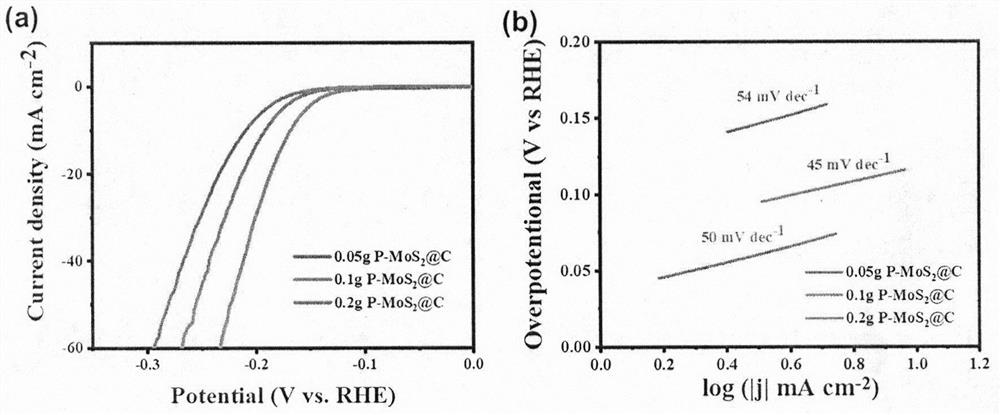

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com