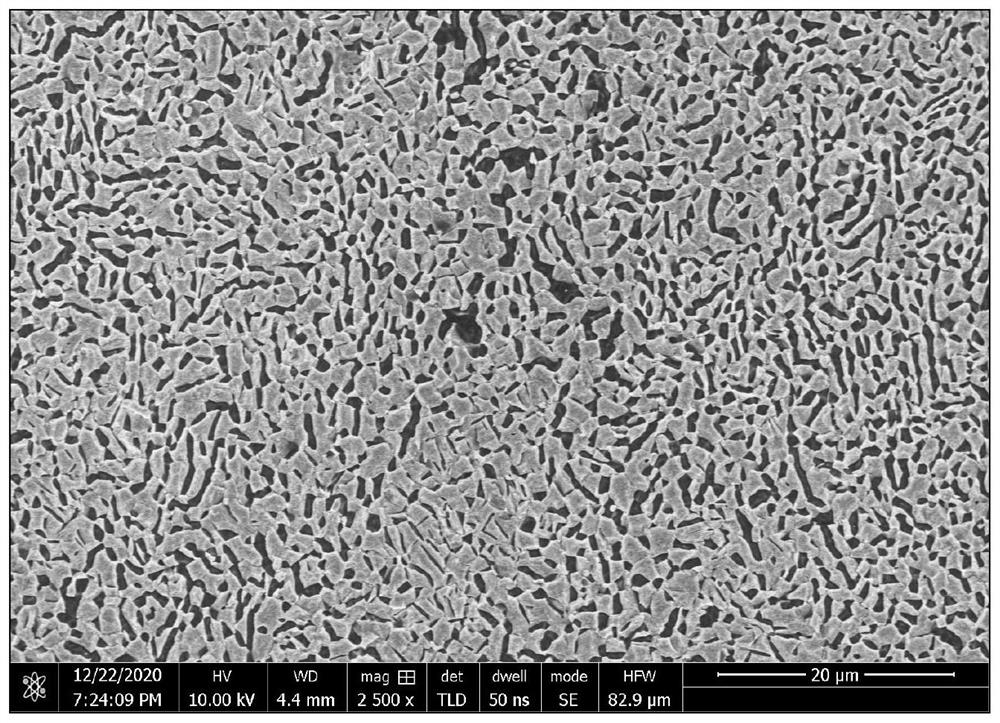

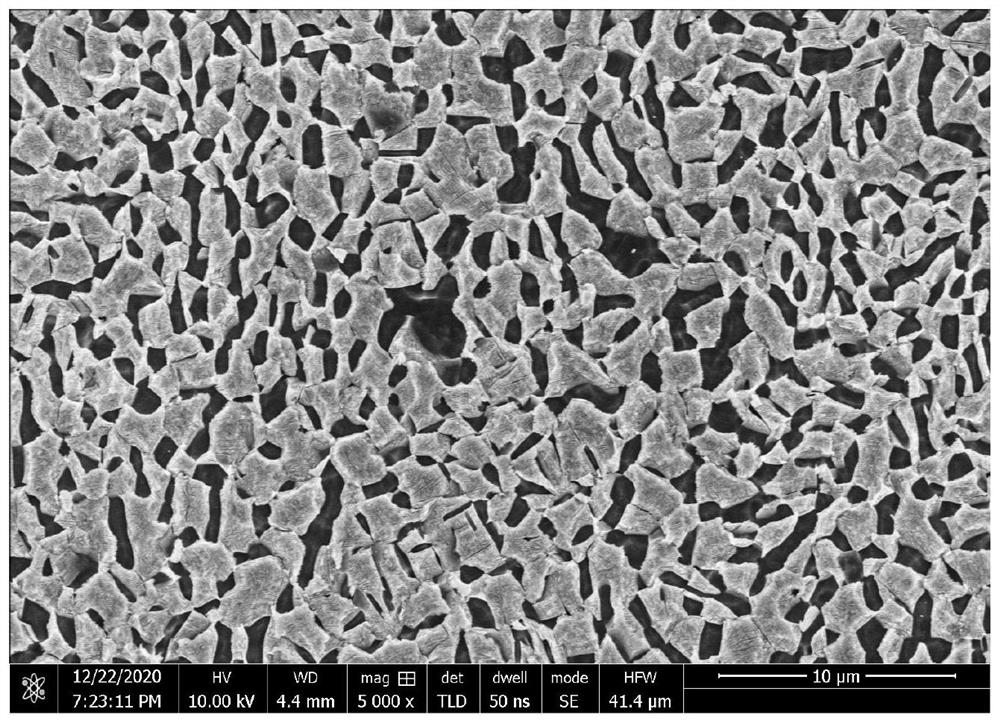

Method for constructing porous tantalum on surface of titanium-tantalum alloy by means of electrochemistry

A porous tantalum, electrochemical technology, applied in the field of biomedical materials, can solve the problems of lack of bone-promoting activity, stimulation of osteoblast proliferation and differentiation, lack of antibacterial ability, etc., to improve biocompatibility and biological activity, good The ability to induce bone regeneration and the effect of improving implant safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment includes the following steps:

[0053] Step 1, mixing concentrated nitric acid, hydrogen peroxide and water to obtain an electrolyte; the mass fraction of the concentrated nitric acid is 68%, and the mass fraction of the hydrogen peroxide is 30%; the volume fraction of the concentrated nitric acid in the electrolyte is 2 %, the volume fraction of hydrogen peroxide is 1%;

[0054] Step 2, polishing, cleaning and drying the titanium-tantalum alloy in sequence to obtain a sample; the titanium-tantalum alloy is a titanium-tantalum alloy sheet, and the mass fraction of tantalum in the titanium-tantalum alloy is 30%; the polishing is Carry out grinding treatment, the process of described grinding treatment is: carry out grinding treatment with 800#, 1000#, 1500# and 2000# sandpaper successively; The process of described cleaning is: successively in acetone, ethanol and deionized water ultrasonic cleaning; The drying conditions are: keep warm for 30 minutes at...

Embodiment 2

[0060] This embodiment includes the following steps:

[0061] Step 1, mixing concentrated nitric acid, hydrogen peroxide and water to obtain an electrolyte; the mass fraction of the concentrated nitric acid is 68%, and the mass fraction of the hydrogen peroxide is 30%; the volume fraction of the concentrated nitric acid in the electrolyte is 0.5% %, the volume fraction of hydrogen peroxide is 0.5%;

[0062] Step 2, polishing, cleaning and drying the titanium-tantalum alloy in sequence to obtain a sample; the titanium-tantalum alloy is a titanium-tantalum alloy sheet, and the mass fraction of tantalum in the titanium-tantalum alloy is 30%; the polishing is Carry out grinding treatment, the process of described grinding treatment is: carry out grinding treatment with 800#, 1000#, 1500# and 2000# sandpaper successively; The process of described cleaning is: successively in acetone, ethanol and deionized water ultrasonic cleaning; The drying conditions are: keep warm for 20 minut...

Embodiment 3

[0068] This embodiment includes the following steps:

[0069] Step 1, mixing concentrated nitric acid, hydrogen peroxide and water to obtain an electrolyte; the mass fraction of the concentrated nitric acid is 68%, and the mass fraction of the hydrogen peroxide is 30%; the volume fraction of the concentrated nitric acid in the electrolyte is 1 %, the volume fraction of hydrogen peroxide is 0.8%;

[0070] Step 2, polishing, cleaning and drying the titanium-tantalum alloy in sequence to obtain a sample; the titanium-tantalum alloy is a titanium-tantalum alloy sheet, and the mass fraction of tantalum in the titanium-tantalum alloy is 30%; the polishing is Carry out grinding treatment, the process of described grinding treatment is: carry out grinding treatment with 800#, 1000#, 1500# and 2000# sandpaper successively; The process of described cleaning is: successively in acetone, ethanol and deionized water ultrasonic cleaning; The drying conditions are: at 80°C, keep warm for 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com