Heteroatom in-situ doped porous carbon composite lithium negative electrode and preparation method and application thereof

An in-situ doping and heteroatom technology is applied in the field of porous carbon composite lithium anode and its preparation, which can solve the problems of inability to effectively improve lithium deposition-dissolution behavior and difficulty in improving battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] (1) Preparation of hypercrosslinked polymer precursor

[0039] Solvothermal method

[0040] Adding reaction monomers, cross-linking agents, and catalysts into the solvent to obtain a reaction mixture; transferring the reaction mixture to a reaction kettle, and reacting at 60-100° C. for 10-36 hours to obtain a reaction product; the reaction product is washed, Purify and vacuum dry to obtain a hypercrosslinked polymer precursor; the volume ratio of the reaction monomer to the crosslinking agent is 0.5:4-2:1.

[0041] Solution method

[0042] Add the reaction monomer into the solvent, then add the cross-linking agent in the protective atmosphere, then add the catalyst, and react under reflux at 60-100°C for 10-36 hours to obtain the reaction product; the reaction product is washed, purified and vacuum-dried, A hypercrosslinked polymer precursor is obtained; the molar ratio of the reactive monomer to the crosslinking agent is 0.5:4-2:1.

[0043] In this scheme, the cros...

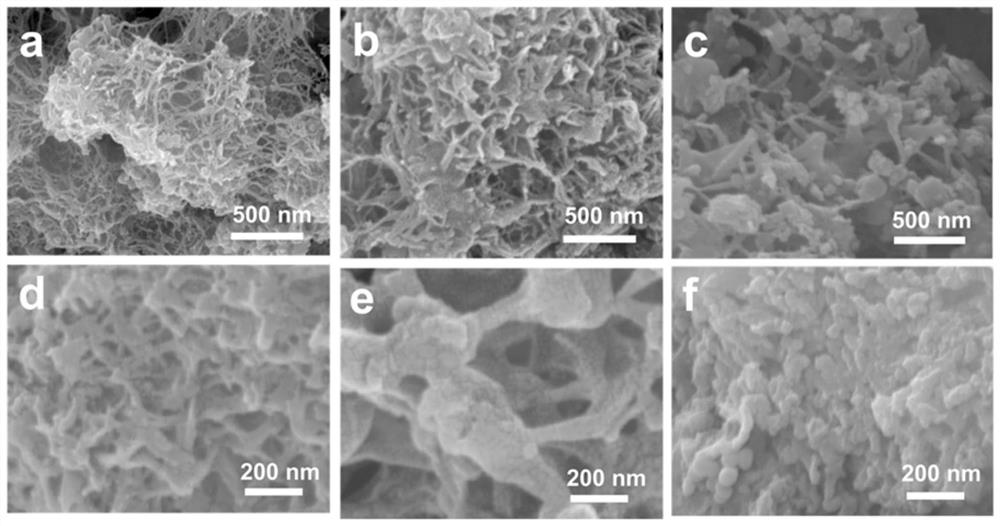

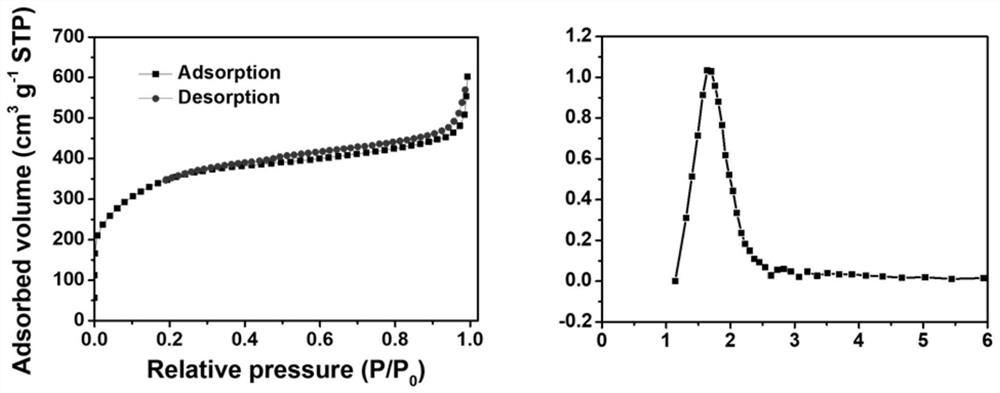

Embodiment 1

[0049] Embodiment 1 (solution method)

[0050] (1) Add 0.05mol of monomer aniline to 100mL 1,2-dichloroethane, 2 Add 0.1mol dimethoxyethane (FDA) under protection, stir well to make it evenly mixed;

[0051] (2) Add 0.1 mol ferric chloride, stir at 45°C for 5 hours for pre-polymerization, heat up to 80°C and reflux for 19 hours. The product was repeatedly washed with methanol and ultrapure water, purified by a Soxhlet extractor for 24 hours, and dried under vacuum at 70°C for 24 hours to obtain a hypercrosslinked polymer precursor, denoted as HCP-An;

[0052] (3) 1.0g precursor HCP-An and 4.0g KOH were mixed well, and 2 Under protection, the temperature was raised to 900°C at a rate of 5°C / min, kept for 2h, cooled to 30°C, washed thoroughly with 2M hydrochloric acid and ultrapure water respectively, and the final product was vacuum-dried at 50°C for 24h to obtain nitrogen-doped porous carbon NPC-An-900.

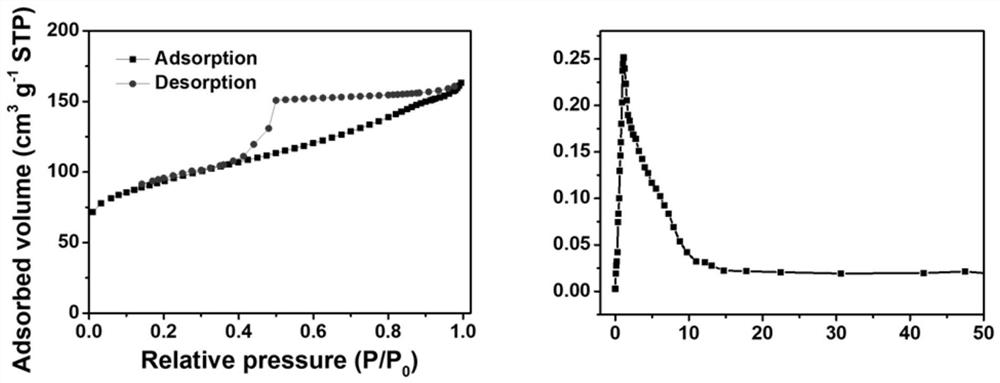

Embodiment 2

[0053] Embodiment 2 (solvothermal method)

[0054] (1) Add 1mL of pyrrole monomer to 30mL of solvent 1,2-dichloroethane, add 3mL of FDA for ultrasonic dispersion to mix evenly, then add 5g of ferric chloride, and mix well;

[0055] (2) Transfer the above solution to the polytetrafluoroethylene liner of the stainless steel reactor, and react at 90°C for 20h;

[0056] (3) Wash the product repeatedly with methanol and ultrapure water, purify it with a Soxhlet extractor for 24 hours, and dry it under vacuum at 70°C for 24 hours to obtain a hypercrosslinked polymer precursor, which can be recorded as HCP-Py;

[0057] (4) 1.0g of precursor HCP-Py and 4.0g of KOH were mixed well, raised to 900°C at a rate of 5°C / min under the protection of Ar, kept for 2h, cooled to 30°C, and then washed with 1.5M hydrochloric acid and ultrapure After fully washing with water, the final product was vacuum-dried at 70 °C for 24 h to obtain the oxygen-doped porous carbon NPC-Py-900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com