Preparation method of anhydrous magnesium chloride

A technology of anhydrous magnesium chloride and magnesium chloride, applied in the direction of magnesium chloride, chemical instruments and methods, magnesium halide, etc., can solve the problems that chlorine cannot be recycled, doubtful about safety, difficult to electrolyze raw materials, etc., and achieve low production cost, high quality, Product quality is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Most of the existing technological routes for preparing anhydrous magnesium chloride are researched around the problem of magnesium chloride dehydration itself, and in essence they all directly remove water molecules from magnesium chloride. Only the magnesium chloride double salt and complex decomposition dehydration method is to convert magnesium chloride into a coordination compound first, and then carry out high-temperature deamination. Inventor explores the preparation process of anhydrous magnesium chloride, finds that can react in anhydrous organic solvent by anhydrous magnesium formate or magnesium chloride hexaammoniate and hydrogen chloride gas, generates anhydrous magnesium chloride and formic acid, removes anhydrous organic solvent and Formic acid, or remove ammonium chloride, can obtain high-quality anhydrous magnesium chloride, and prepare anhydrous magnesium chloride compared with directly removing the crystal water in the magnesium chloride with crystal w...

Embodiment 1

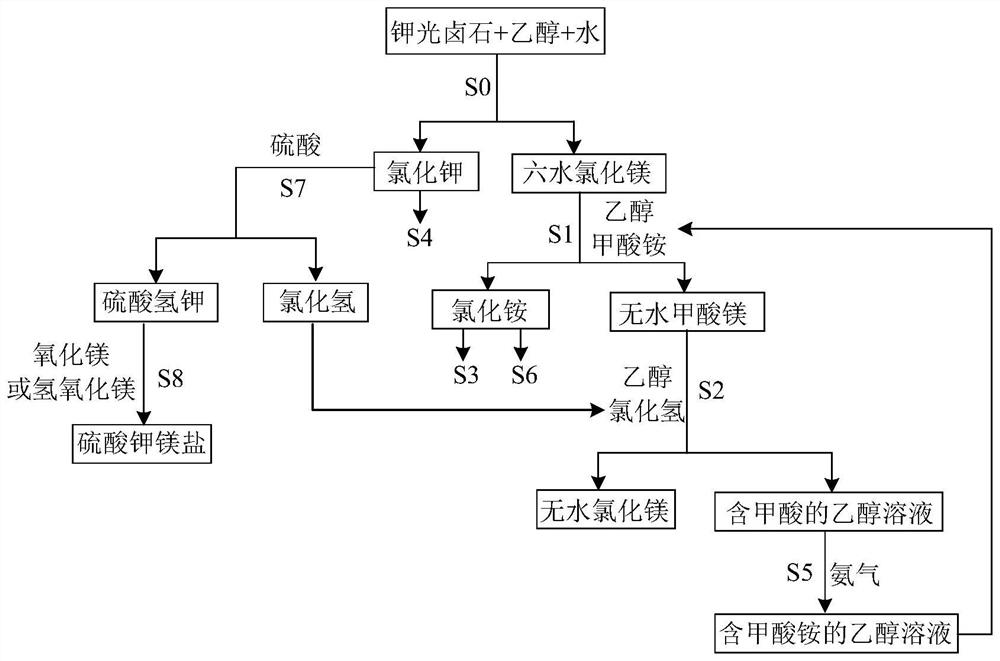

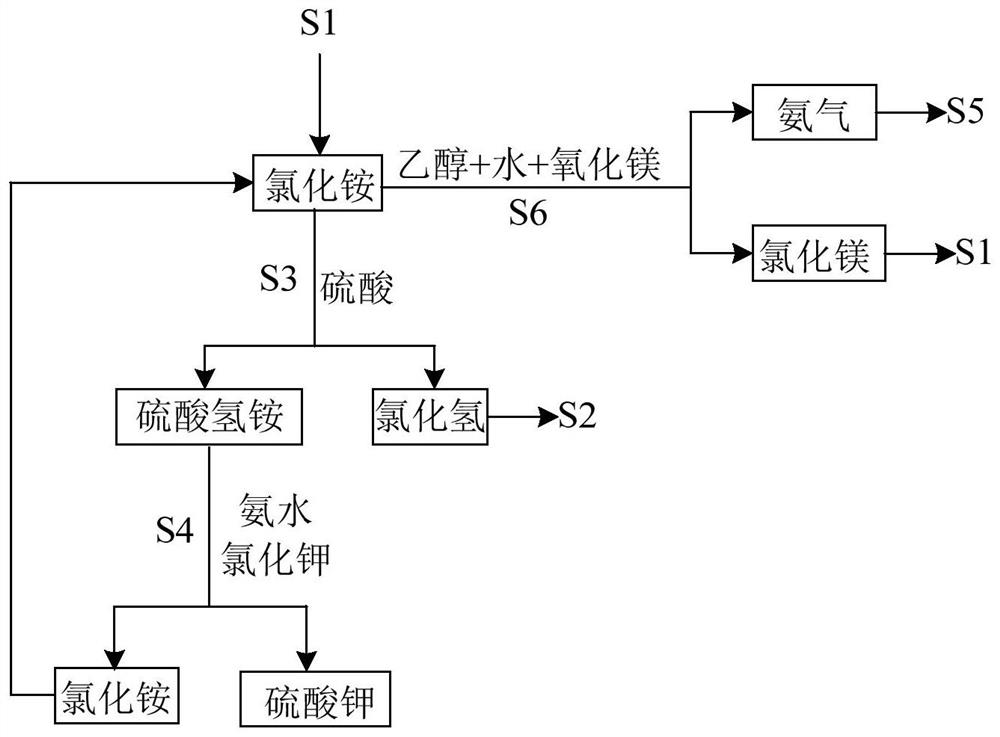

[0048] Such as figure 1 and 2 Shown, with potassium carnallite (KCl MgCl 2 ·6H 2 O) be initial raw material, the preparation method of anhydrous magnesium chloride comprises the steps:

[0049] S0, potassium carnallite is ground into fine powder, after passing through a 100-mesh vibrating sieve, it is separated into potassium chloride (crystal precipitation) and magnesium chloride hexahydrate (dissolved in ethanol) in an ethanol-water solvent, and potassium chloride is removed by filtration , to obtain magnesium chloride hexahydrate; wherein, the removed potassium chloride has a purity>99%, step S4 can be carried out, and ammonium chloride and potassium sulfate can be reacted in step S4 to generate ammonium chloride and potassium sulfate, step S7 can also be carried out, and it can also be used as a product to the outside world Sold, and magnesium chloride hexahydrate carries out step S1;

[0050] S1, magnesium chloride hexahydrate is metathesis-reacted with ammonium forma...

Embodiment 2

[0064]The dried magnesium chloride hexaammoniate powder is put into 1L of anhydrous methanol, reacts with anhydrous hydrogen chloride in a closed container at 0-30°C and 0-3Mpa pressure to synthesize anhydrous magnesium chloride, and obtains by-product ammonium chloride (ammonium chloride micro Soluble in methanol, most of it precipitates out). After the ammonium chloride is removed by filtration, the solvent is distilled off under reduced pressure to obtain anhydrous magnesium chloride, further vacuum-dried under the protection of nitrogen, the solvent is fully removed, and then the temperature is raised to above 340°C to fully volatilize the residual ammonium chloride, namely About 95g of high-purity anhydrous magnesium chloride can be obtained, with a purity of >99.5%. Among them, after the filtered ammonium chloride is dried under negative pressure to remove the residual solvent, about 320 g is recovered in the form of by-products, which can be directly sold or recycled as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com