Temperature-sensitive controlled-release nano pesticide vesicle as well as preparation method and application thereof

A nano-pesticide and vesicle technology, applied in the fields of botanical equipment and methods, applications, biocides, etc., can solve the problems of polluting food pesticides, residues, serious environmental problems, etc., to improve the effective utilization rate, suitable for industrial production, and cheap raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing temperature-sensitive controlled-release nano-pesticide vesicles, comprising the following steps:

[0022] (1) Suzuki reaction occurs between bromotriphenylethylene and 4-hydroxyphenylboronic acid pinacol ester to obtain 4-(1,2,2-triphenylvinyl)phenol.

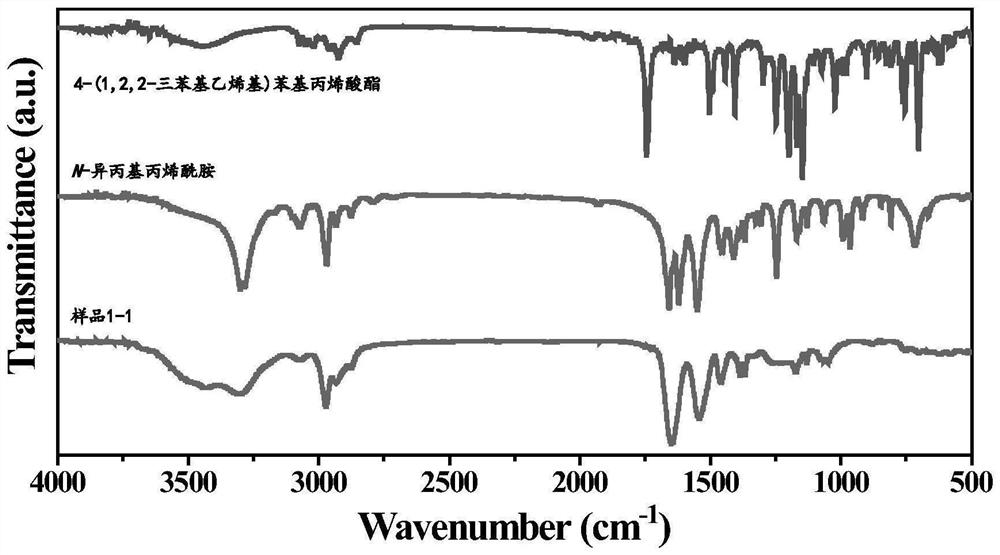

[0023] (2) Substituting the 4-(1,2,2-triphenylvinyl)phenol with acryloyl chloride to obtain 4-(1,2,2-triphenylvinyl)phenyl acrylate .

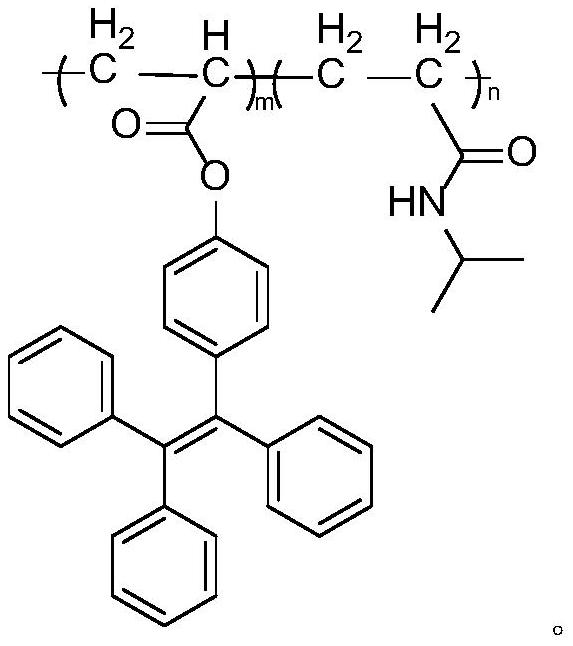

[0024] (3) The 4-(1,2,2-triphenylvinyl)phenyl acrylate and N-isopropylacrylamide undergo a reversible addition-fragmentation chain transfer polymerization reaction under the action of an initiator, A thermosensitive polymer is obtained.

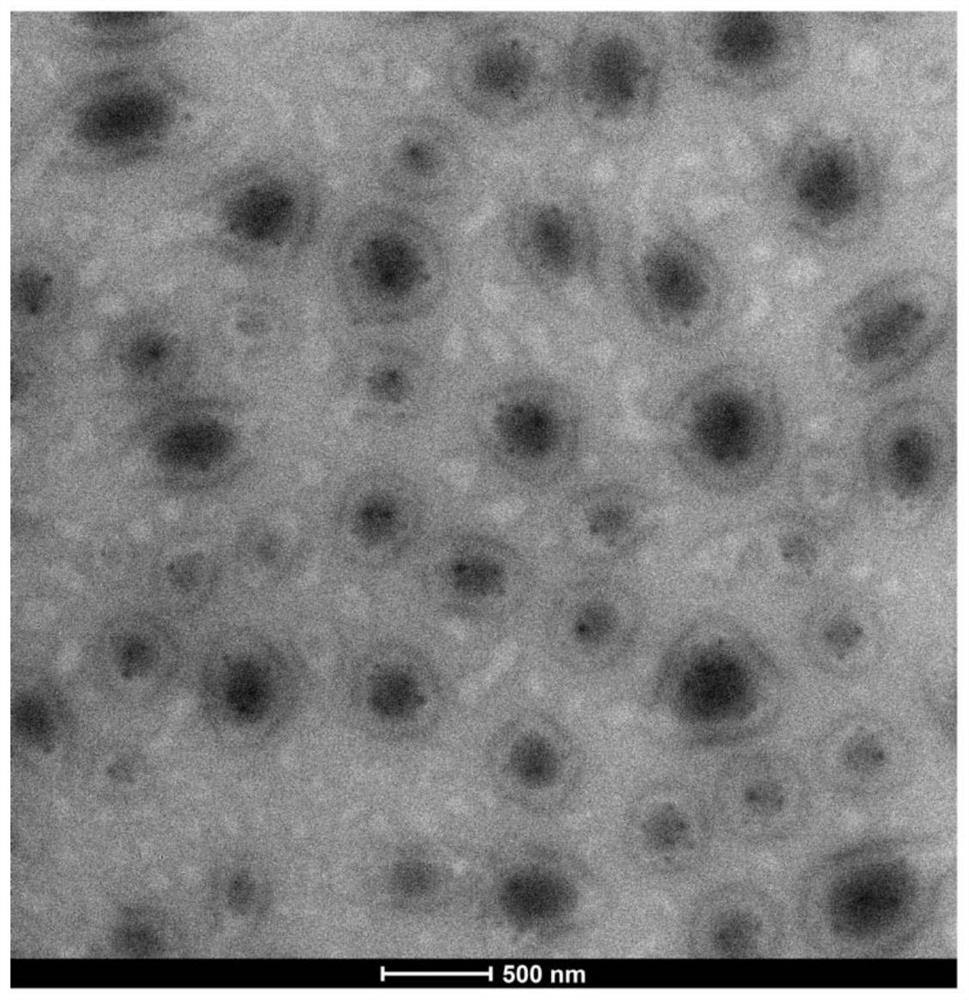

[0025] (4) The temperature-sensitive polymer and thiamethoxam are self-assembled to prepare temperature-sensitive controlled-release nanopesticide vesicles.

[0026] In the invention, bromotriphenylethylene, 4-hydroxyphenylboronic acid pinacol ester and catalyst are mixed to undergo Suzuki reaction to ob...

Embodiment 1

[0037] The preparation method of 4-(1,2,2-triphenylvinyl)phenol is:

[0038] Into a 250 mL dry single-necked round bottom flask, bromotriphenylethylene (2.0 g), 4-hydroxyphenylboronic acid pinacol ester (1.4 g), tetrakis(triphenyl)phosphine palladium (0.5 g) and potassium carbonate were successively added (3.7g), after nitrogen replacement, 1,4-dioxane (90mL) and distilled water (30mL) were added in sequence. The round bottom flask was placed at 100°C for 16h. After the reaction was completed and cooled to room temperature, the reaction solution was extracted with ethyl acetate, washed three times with saturated aqueous sodium chloride solution, and the organic phase was collected. The organic phase was dried over anhydrous sodium sulfate, filtered, and ethyl acetate was distilled off under reduced pressure to obtain a crude product. The crude product was separated and purified through a silica gel column using petroleum ether and ethyl acetate (volume ratio 60:1) as the elu...

Embodiment 2

[0041] The preparation method of 4-(1,2,2-triphenylethenyl) phenyl acrylate is:

[0042] 4-(1,2,2-Triphenylethenyl)phenol (1 g) and dry dichloromethane (30 mL) were successively added into a dry 50 mL double-necked round bottom flask and fully dissolved. While stirring, the temperature of the reaction solution was lowered to 0°C. Subsequently, triethylamine (0.6 g) was added into the round bottom flask, and the temperature of the system was continued to be maintained at 0°C. Finally, acryloyl chloride (0.4 g) was slowly added dropwise into the round bottom flask, and reacted at 0° C. for 4 h. After the reaction is complete, a small amount of distilled water is added to the round bottom flask to quench unreacted acryloyl chloride. The resulting reaction solution was left standing to separate layers, washed 3 times with saturated sodium chloride solution, and the organic phase was collected. The organic phase was dried over anhydrous sodium sulfate, filtered, and dichlorometh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com