Preparation method of single-component early-strength quick-setting geopolymer

A geopolymer and one-component technology, which is applied in the field of preparation of one-component early-strength quick-setting geopolymers, can solve the problems of large differences in product performance of geopolymer materials, large differences in the ratio of silicon and aluminum elements, and Problems such as large differences in activity of mineral components, to achieve the effect of improving volume stability, increasing fineness and specific surface area, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

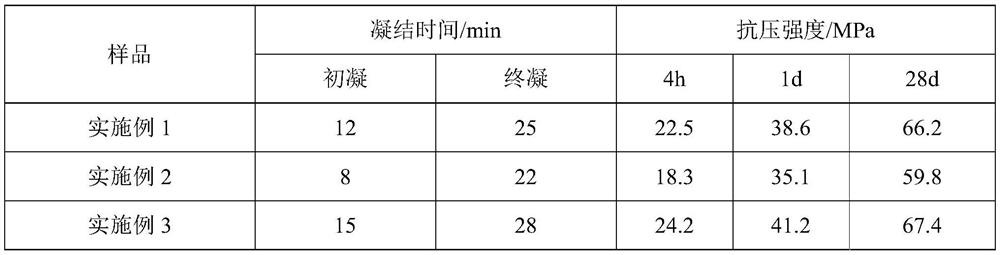

Embodiment 1

[0025] A single-component early-strength and quick-setting geopolymer material. The raw materials include the following components: 28 parts of red mud, 35 parts of blast furnace slag, 7 parts of anhydrite, 20 parts of solid activator, 8 parts of fly ash, and additives 2 servings.

[0026] The solid activator is a mixture of caustic alkali and sodium silicate in a weight ratio of 1:10, the admixture is 0.5 parts of polycarboxylate water reducer, and 1.5 parts of redispersible latex powder.

[0027] A preparation method of a one-component early-strength quick-setting geopolymer material, comprising the following steps:

[0028] 1) Put the dried red mud, blast furnace slag, and anhydrite into a rotary kiln for calcination, the calcination temperature is 800°C, the calcination time is 3h, and cool for later use;

[0029] 2) Preliminarily crush the cooled mixed material, add solid activator and fly ash, send it into the vertical mill, fully mix the material and grind it fully unt...

Embodiment 2

[0032] A single-component early-strength quick-setting geopolymer material. The raw materials include the following components: 25 parts of red mud, 40 parts of blast furnace slag, 7 parts of anhydrite, 18 parts of solid activator, 7.5 parts of fly ash, and additives 2.5 servings.

[0033] The solid activator is a mixture of caustic alkali and sodium silicate in a weight ratio of 1:10, and the admixtures are 0.5 parts of polycarboxylate superplasticizer and 1.5 parts of sodium bentonite.

[0034] A preparation method of a one-component early-strength quick-setting geopolymer material, comprising the following steps:

[0035] 1) Put the dried red mud, blast furnace slag, and anhydrite into a rotary kiln for calcination, the calcination temperature is 900°C, the calcination time is 2h, and cool down for later use;

[0036]2) Preliminarily crush the cooled mixed material, add solid activator and fly ash, send it into the vertical mill, fully mix the material and grind it fully u...

Embodiment 3

[0039] A single-component early-strength quick-setting geopolymer material. The raw materials include the following components: 30 parts of red mud, 38 parts of blast furnace slag, 5 parts of anhydrite, 16.5 parts of solid activator, 9.2 parts of fly ash, and additives 1.3 servings.

[0040] The solid activator is a mixture of caustic soda and sodium silicate in a weight ratio of 1:10, and the admixtures are 0.2 parts of polycarboxylate superplasticizer, 1 part of sodium bentonite, and 0.1 part of cellulose ether.

[0041] A preparation method of a one-component early-strength quick-setting geopolymer material, comprising the following steps:

[0042] 1) Put the dried red mud, blast furnace slag, and anhydrite into a rotary kiln for calcination, the calcination temperature is 1000°C, the calcination time is 1h, and it is cooled for later use;

[0043] 2) Preliminarily crush the cooled mixed material, add solid activator and fly ash, send it into the vertical mill, fully mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com