Photosensitizer and preparation method thereof

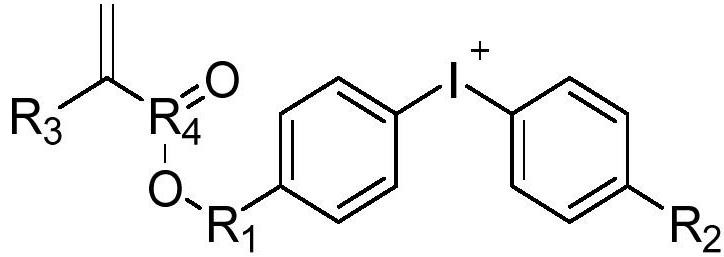

A photosensitizer and carbon number technology, applied in the preparation of sulfonates, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of weak performance of photosensitizers, inability to disperse uniformly, etc., and achieve simple steps and good appearance. and line width roughness, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

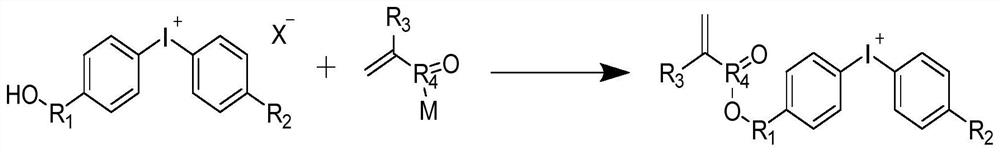

Method used

Image

Examples

Embodiment 1

[0040] Provided in this example is (4-(methacryloyloxy)phenyl)(p-tolyl)iodonium as a photosensitizer and its preparation method. In the preparation process of this implementation, 34.66g of 4-hydroxyl, 4-methyldiphenyliodonium chloride salt was added to the reaction flask, 150ml of dichloromethane was added, dissolved, and 11.5g of triethylamine solution was added dropwise. The reaction flask was stirred at room temperature for 0.5 h under nitrogen protection, and then cooled to -5 °C. In another reaction bottle, pre-mix 11.7 g of methacryloyl chloride and dissolve in 30 ml of dichloromethane, slowly control the dropping speed, add the mixed solution of methacryloyl chloride, and control the temperature at -5°C. After the dropwise addition of the methacryloyl chloride mixture was completed, the mixture was stirred at -5°C for 1 h. After stirring at -5°C for 1h, the temperature was naturally raised to 25°C, and then stirred for 2h. The mixture was filtered, the filter cake wa...

Embodiment 2

[0045] In the present embodiment, the preparation process of the photosensitizer is as follows: add 28.9g 4-hydroxyl, 4-tert-butyldiphenyliodonium chloride salt in the reaction flask, add 150ml of dichloromethane, dissolve it, add dropwise 11.5 g triethylamine solution. Stir at room temperature for 0.5 h under nitrogen protection, then cool to -5°C. In another reaction bottle, 11.7 g of methacryloyl chloride was pre-mixed and dissolved in 30 ml of methylene chloride. Slowly control the dropping rate, add the methacryloyl chloride mixture, and control the temperature at -5°C. After the dropwise addition of the methacryloyl chloride mixture was completed, the mixture was stirred at -5°C for 1 h. Stir at -5 °C for 1 h, then naturally warm up to 25 °C, and stir for 2 h. After filtering, the filter cake was washed with 30 ml of dichloromethane, and the filtrate was washed twice with 10 ml of pure water. Concentrate the filtrate and control the temperature at 35°C. 39.1 g of (4...

Embodiment 3

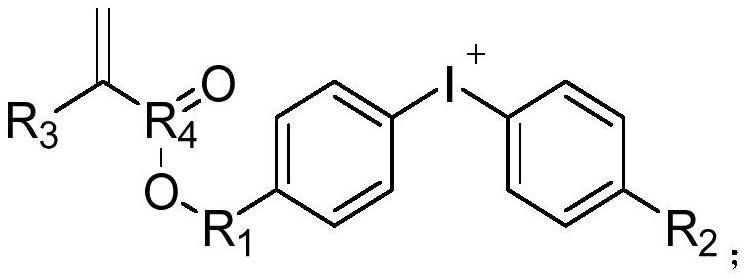

[0049]In this example, the preparation process of the photosensitizer is as follows: add 42.9g (4-((methacryloyloxy)methyl)phenyl)(p-tolyl)iodonium into the flask, add 200g purified Mixture of water and 100ml methanol, dissolve clear. Add 30 g of methanol aqueous solution of 1,1,2,2,3,3-hexafluoropropane-1,3-disulfonylimide salt into another reaction bottle, and it is in a clear state. As the addition proceeded, a white solid precipitated out. Stir overnight at room temperature. Desolvation, add 250ml of dichloromethane, stir, wash with 100ml of purified water*3 times, and desolventization to obtain 63.8g of the target product (4-((methacryloxy)methyl)phenyl)(p-tolyl) The yield of iodonium 1,1,2,2,3,3-hexafluoropropane-1,3-disulfonylimide salt was 93.2%.

[0050] Its reaction formula is:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com