Method for simultaneously determining vitamins K1 and K2 in milk powder and application

A vitamin and milk powder technology, applied in the field of analytical chemistry, can solve the problems of incomplete impurity removal, low measurement results, late peak time, etc., and achieve the effects of ensuring accuracy and reproducibility, simplifying operation steps, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Preparation of the sample solution to be tested:

[0083] Weigh 1g of milk powder sample, ①enzyme hydrolysis: add 10mL water, a certain amount of lipase aqueous solution, vortex for 2-3min, place in a constant temperature water bath at 37±2°C for 2-3 hours;

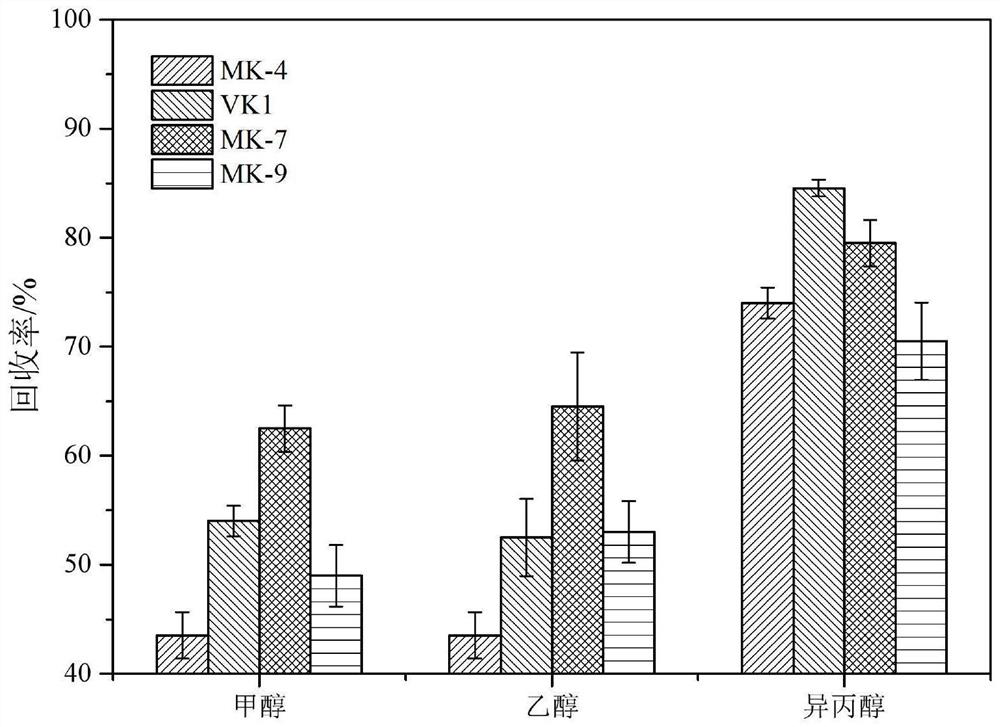

[0084] ②Constant volume: Add 10mL of anhydrous isopropanol and 1mL of 5mol / L KOH aqueous solution (or 1.2mL of 14.65mol / L phosphoric acid) to the sample enzymatic hydrolysis solution, dilute to 25mL with 50wt.% isopropanol aqueous solution, and take 2mL Pass through a 0.45 μm filter membrane and wait for analysis on the machine.

Embodiment 1

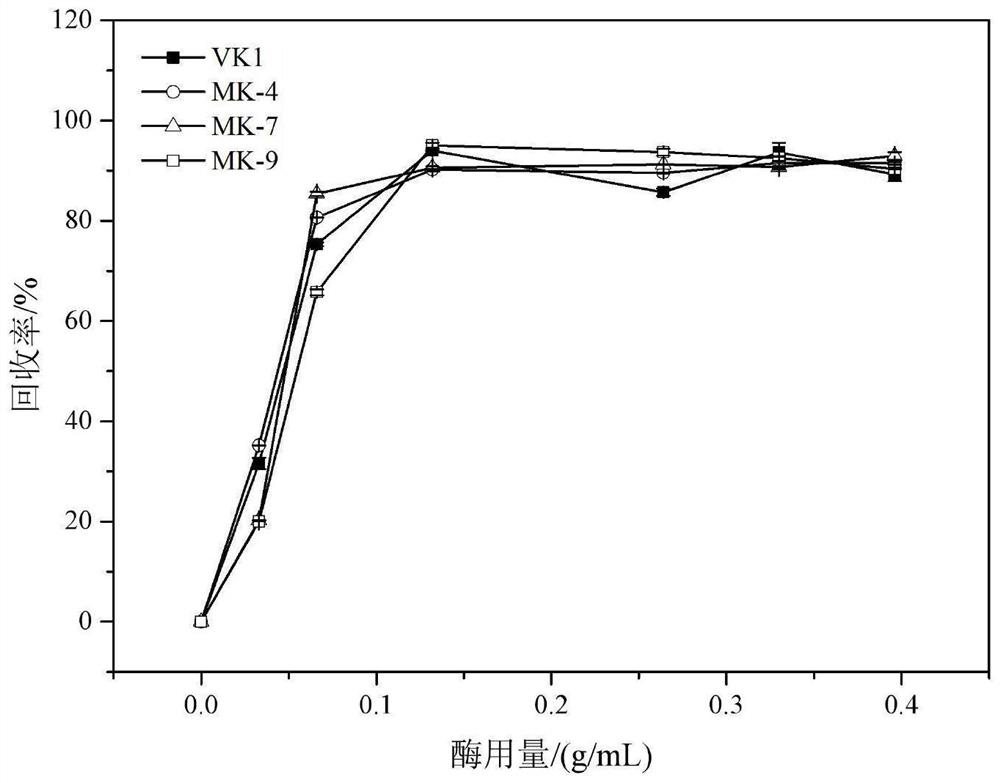

[0087] This embodiment has measured lipase adding concentration to vitamin K 1 with K 2 The influence of extraction recovery rate, the specific process is: prepare lipase aqueous solutions with different concentrations of 0-0.40g / mL, dissolve lipase at 30°C for 15 minutes, and wait for no particles at the bottom, add 3mL to the sample to be tested, and enzymatically hydrolyze overnight, and the vitamin K in the sample solution after overnight enzymatic digestion 1 and vitamin K 2 content was tested.

[0088] figure 1 is the concentration of lipase added to vitamin K 1 and vitamin K 2 The influence diagram of extraction recovery rate, as shown in the figure, under enzymatic hydrolysis conditions, when the concentration of lipase added is 0.13g / mL~0.16g / mL, vitamin K 1 and vitamin K 2 The recovery rate is the highest; when the concentration of lipase added is lower than 0.13g / mL, the fat of milk powder is not completely enzymatically hydrolyzed, which affects the release ...

Embodiment 2

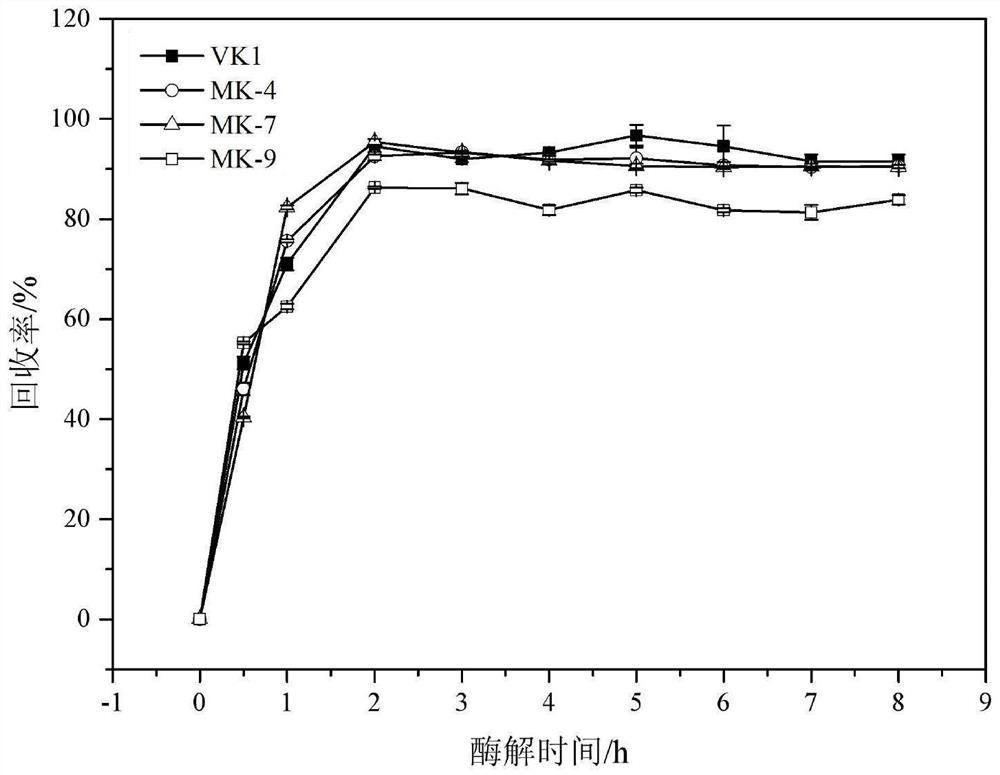

[0090] This embodiment has measured the effect of lipase enzymolysis time on vitamin K 1 with K 2 The influence of extraction recovery rate, the specific process is: add 3mL of 0.13g / mL lipase solution to the sample solution, and observe the influence of milk powder enzymatic hydrolysis time on the recovery rate of four kinds of vitamin K. Select the range of 1h ~ 8h to measure the recovery rate of vitamin K.

[0091] Such as figure 2 As shown, the recovery rate of vitamin K gradually increased from enzymatic hydrolysis for 0h to 2h; the recovery rate of vitamin K was the highest after enzymatic hydrolysis for 2h to 3h; and unstable. Experiments show that the enzymatic hydrolysis time of lipase is too short and the enzymatic hydrolysis is incomplete, which will affect the subsequent vitamin K 1 and vitamin K 2 It was determined that the extraction efficiency tended to be stable when the enzymolysis time was more than 2 hours. If the enzymatic hydrolysis time exceeds 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com