All-solid-state lithium ion battery composite positive electrode diaphragm and manufacturing method thereof

A lithium-ion battery and cathode film technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as reducing the cycle stability of all-solid-state lithium-ion batteries, reducing material capacity, lithium-nickel mixed discharge, etc., to achieve Avoid the effects of low battery capacity retention, inhibit particle breakage, and inhibit phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention provides a method for preparing a full solid-state lithium ion battery composite positive electrode diaphragm, comprising the steps of:

[0057] Includes the following steps:

[0058] S1, prepare non-cobalt high nickel lithium ion positive active materials;

[0059] S2, the cobalt-free high nickel lithium ion positive electrode active material is mixed with solid electrolyte, conductive agent, and adhesive to obtain a positive electrode diaphragm material;

[0060] S3, the positive electrode diaphragm raw material is fully solid-state lithium ion battery composite positive electrode diaphragm;

[0061] The addition ratio of the cobalt-free high nickel lithium ion positive electrode active material and solid electrolyte is (7 to 9): (1 to 2).

[0062] The preparation method of a fully solid-state lithium ion battery composite positive electrode diaphragm provided by the present invention is prepared from the solid electrolyte, the conductive agent, and t...

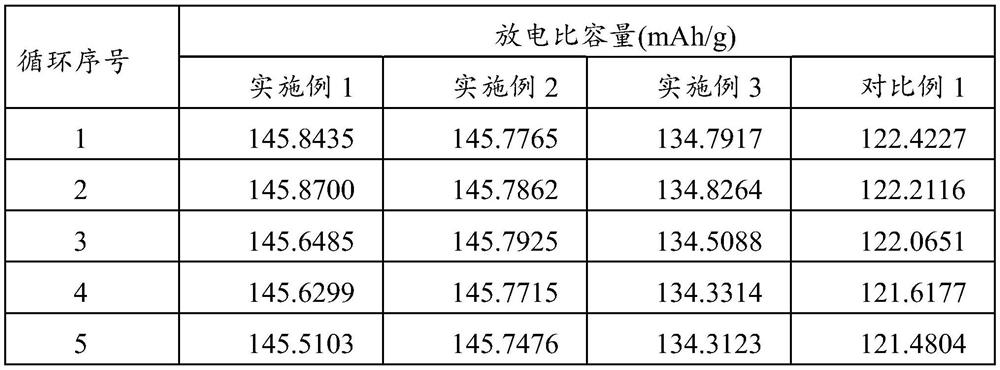

Embodiment 1

[0110] A preparation method of a full solid state lithium ion battery composite positive electrode diaphragm, including the following steps:

[0111] S1, preparing a cobalt-free high nickel lithium ion positive electrode active material;

[0112] (1), in accordance with molar ratio 9: 1, hexahydrate sulfate and a hydrosulfate sulfate, and dissolved in 500 ml of deionized water to dissolve the first solution.

[0113] (2), a 0.7 mol of sodium hydroxide and 0.7 mol of ammonia water were added, and the second solution A and the second solution B for dissolving 500 ml of deionized water were added.

[0114] (3) 500 ml of deionized water was added to the co-precipitated reactor, the circulating water heating system was opened, and the reaction kettle temperature was raised to 55 ° C, and the mixture was stirred with 600 revolutions, and the stirring process passed into an inert atmosphere.

[0115] (4), the first solution and the second solution A, and the second solution B were added ...

Embodiment 2

[0121] A preparation method of a full solid state lithium ion battery composite positive electrode diaphragm, including the following steps:

[0122] S1, preparing a cobalt-free high nickel lithium ion positive electrode active material;

[0123] A. It is called nickel oxy hydroxide and aluminum nitrate. The aluminum nitrate is dissolved in 50 mL deionized water, then citric acid and ammonia water, adjusting pH> 7 to obtain a first mixture, and a nickel hydroxide is added to the first mixture for 3 h, and stirred at 80 ° C to evaporate. The first precursor.

[0124] B. Mix the first precursor and the lithium source compound in accordance with a molar ratio of 1: 1.01, the lithium source compound comprises 99 wt% lithium hydroxide and 1 wt% lithium nitrate, and 0.8% tantalum oxide, resulting Second mixed powder.

[0125] C. At an oxygen atmosphere, the second mixed powder was first touched to 550 ° C for 8 h, and then sintered at 750 ° C for 12 h.

[0126] S2, 80% by weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com