Fluorine-containing copolymer antibacterial hemostatic material, preparation method and application thereof, and sanitary material

A technology of hemostatic material and copolymer, applied in application, drug delivery, pharmaceutical formulation, etc., can solve the problems of poor application performance of hemostatic material, reduce blood loss and bacterial adhesion, excellent antibacterial properties, and excellent clot self-separation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

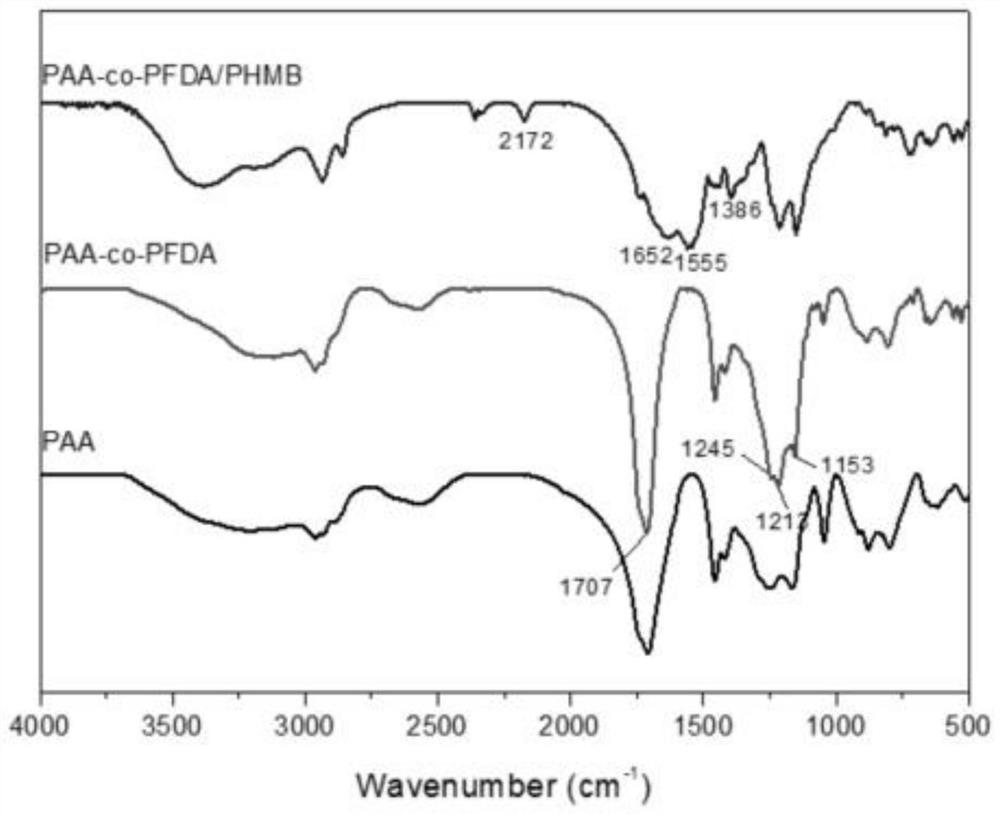

[0037] The invention provides a preparation method of a fluorine-containing copolymer antibacterial and hemostatic material, comprising the following steps:

[0038] S1. Under a protective gas, react the fluorine-containing acrylic monomer, the acrylic monomer and the initiator, and after the reaction, wash to obtain the fluorine-containing acrylic copolymer;

[0039] S2, reacting the fluorine-containing acrylic copolymer and the cross-linking agent, and drying to obtain a cross-linked fluorine-containing acrylic copolymer after the reaction;

[0040] S3. Add the cross-linked fluorine-containing acrylic copolymer into the antibacterial agent solution to react, and after the reaction, obtain the fluorine-containing copolymer antibacterial and hemostatic material through dialysis.

[0041] In the present invention, the fluorine-containing acrylate monomer is perfluoroalkyl acrylate, and the general formula of the perfluoroalkyl acrylate is CH 2 =CRCOO(CH 2 ) m C n f 2n+1 , ...

Embodiment 1

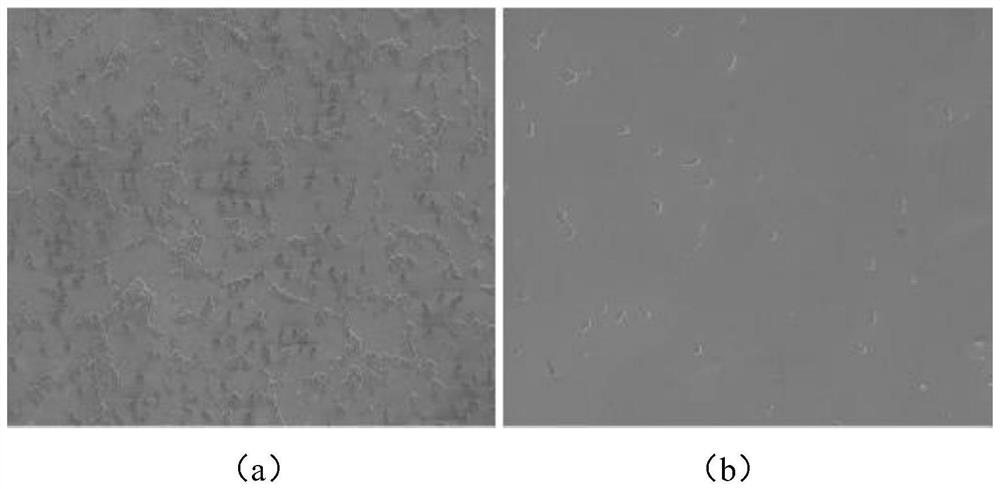

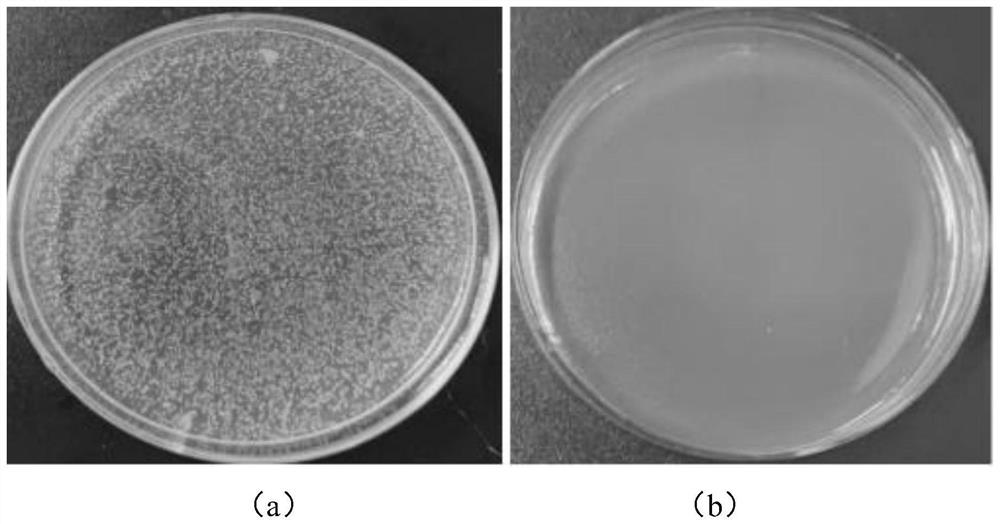

[0062] Dissolve 2-perfluorodecyl ethyl acrylate (PFDA), methacrylic acid and azobisisobutyronitrile at a molar ratio of 1:20:0.125 in tetrahydrofuran (the mass-volume ratio of 2-perfluorodecyl ethyl acrylate to tetrahydrofuran 1g: 17mL) and then added to the three-neck flask, under N 2 Under protection, heat up to 65°C, keep warm for 8 hours, and wash with n-hexane precipitation three times to obtain a fluorine-containing acrylic copolymer; then dissolve the fluorine-containing acrylic copolymer with ultrapure water, and add the carboxyl molar ratio to the acrylic monomer to be 0.05: 1 aziridine, stirred for 1 hour, put the solution in a dialysis bag to remove excess cross-linking agent, and dried the solution in a vacuum oven (65° C.) for 24 hours to obtain a cross-linked fluorine-containing acrylic copolymer; The cross-linked fluorine-containing acrylic copolymer dispersed in pure water was added to the mixed solution of polyhexanide hydrochloride (PHMB 20% solution) and amm...

Embodiment 2

[0069] Dissolve dodecafluoroheptyl methacrylate, acrylic acid and azobisisobutyronitrile at a molar ratio of 1:40:0.15 in tetrahydrofuran (the mass volume ratio of dodecafluoroheptyl methacrylate to tetrahydrofuran is 1g:18mL) and add to the three-necked bottle, in N 2 Under protection, raise the temperature to 75°C, keep it warm for 10 hours, and wash it four times with n-hexane precipitation to obtain the fluorine-containing acrylic copolymer; then dissolve the fluorine-containing acrylic copolymer with ultrapure water, and add the carboxyl molar ratio to the acrylic monomer to be 0.08 : 1 aziridine, after stirring for 1 hour, the solution was placed in a dialysis bag to remove excess cross-linking agent, and the solution was dried in a vacuum oven (70° C.) for 32 hours to obtain a cross-linked fluorine-containing acrylic copolymer; The cross-linked fluorine-containing acrylic copolymer dispersed in pure water was added to the mixed solution of polyhexanide hydrochloride (PH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com