Polyether-ether-ketone hollow fiber membrane as well as preparation method and membrane absorption application thereof

A polyetheretherketone and fiber membrane technology, which is applied in the field of polyetheretherketone hollow fiber hydrophobic membrane for membrane absorption and its preparation, can solve the problem of difficult hydrophobic modification of polyetheretherketone hollow fiber membrane, membrane hydrophobicity and osmotic pressure Insufficient, poor hydrophobic stability and other problems, to achieve the effect of stable membrane structure, avoiding agglomeration and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

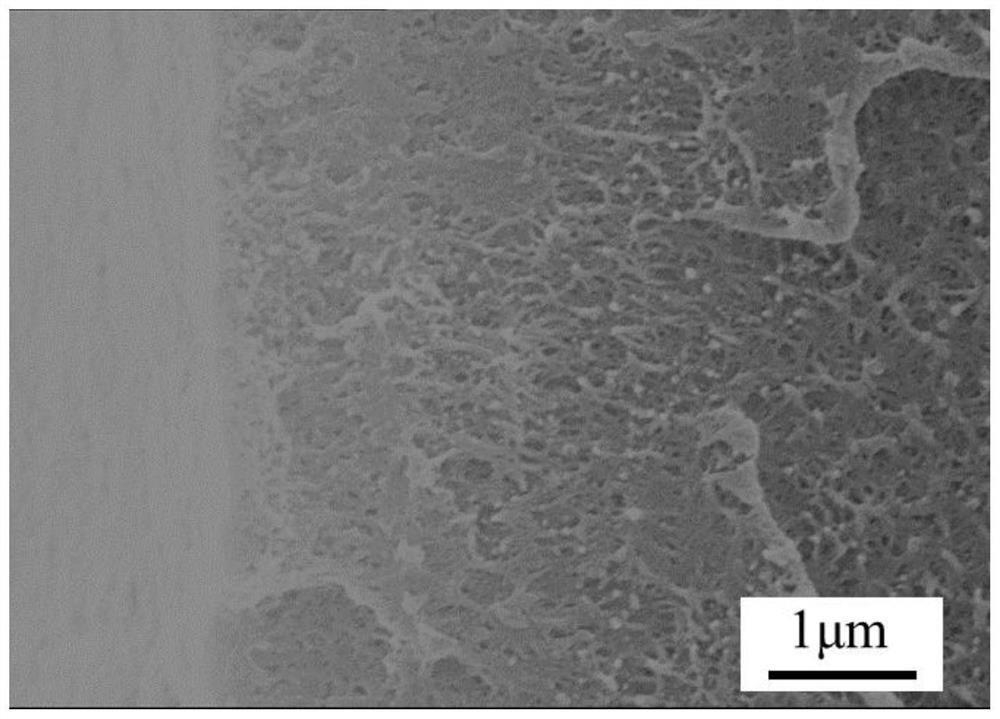

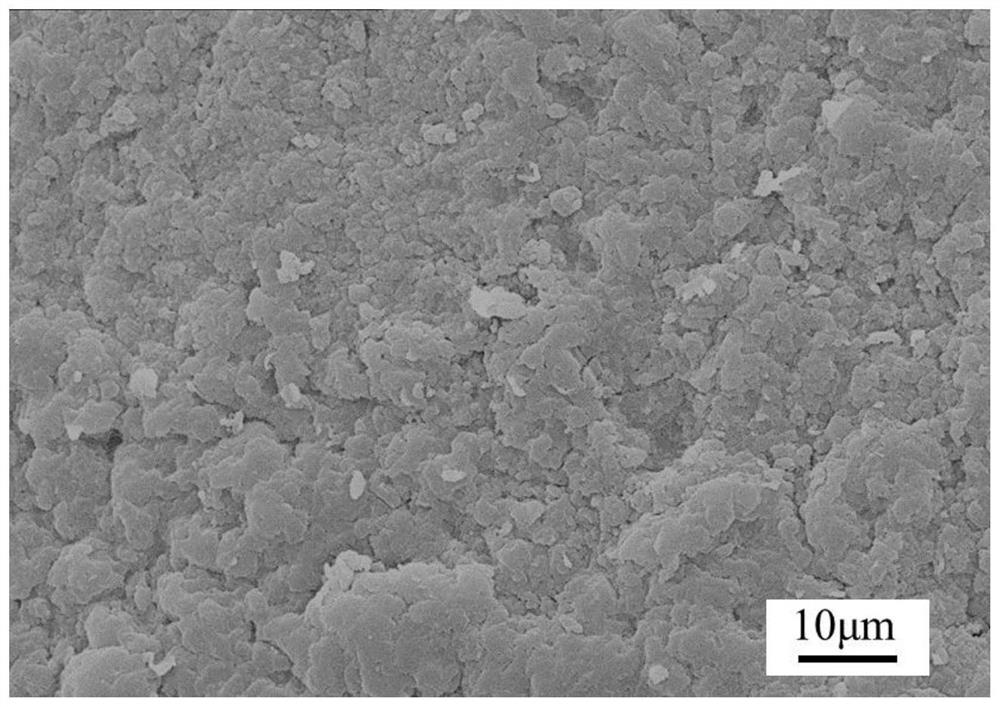

[0029] Step 1. Heat 10 wt% diphenyl sulfone to 180°C to melt, add 5 wt% tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer micropowder, mix and stir evenly at high speed, add 45 wt% PEEK resin, heat up to 340°C, Fully swell and mix evenly, after cooling, pulverize and grind to obtain uniform particles, mix it with 40 wt% polyetherimide porogen through a high-speed mixer; co-extrude through a high-temperature and corrosion-resistant screw extruder Uniform spinning pellets can be obtained after discharging and pelletizing;

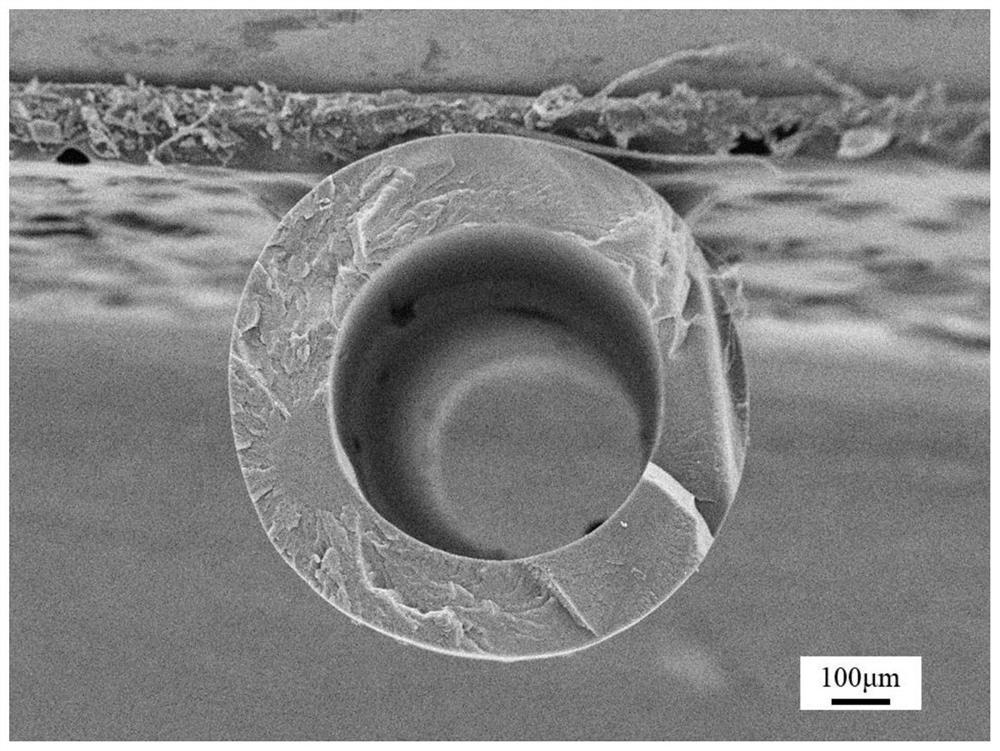

[0030] Step 2. The spinning pellets obtained in step 1 are fully melted at 340°C through a screw extruder, quantitatively extruded through a hollow spinning assembly, the screw speed is 8 r / min, 100°C nitrogen gas is introduced into the assembly, and the spinning melt After the body is solidified in the air bath, the primary hollow fiber membrane is obtained after being cooled and solidified in the coagulation bath. Cut 100 cm membrane filaments and h...

Embodiment 2

[0033] Step 1. Heat 10 wt% diphenyl sulfone to 180°C to melt, add 5 wt% polytetrafluoroethylene micropowder, mix and stir evenly at high speed, add 50 wt% PEEK resin, heat up to 330°C, fully swell and mix evenly, cool and pulverize Grind to obtain uniform particles, which are fully mixed with 35 wt% polyetherimide porogen through a high-speed mixer; blended and extruded through a high-temperature and corrosion-resistant screw extruder, and pelletized to obtain uniform spinning silk pellets;

[0034]Step 2. The spinning pellets obtained in Step 1 are fully melted at 340°C through a screw extruder, and quantitatively extruded through a hollow spinneret assembly. The screw speed is 8 r / min. The inside of the assembly is a PEEK hollow braid with an outer diameter of 1.6 mm. Tube, winding speed 7 m / min. After the spinning melt is solidified in an air bath, it is cooled and solidified in a coagulation bath to obtain a nascent hollow fiber membrane. A 100 cm membrane filament was c...

Embodiment 3

[0037] Step 1. Heat 14 wt% diphenyl isophthalate to 150°C to melt, add 6 wt% polytetrafluoroethylene micropowder, mix and stir evenly at high speed, add 45 wt% PEEK resin, heat up to 340°C, fully swell and mix evenly , after cooling, pulverize and grind to obtain uniform particles, which are fully mixed with 35 wt% polyetherimide porogen through a high-speed mixer; Obtain uniform spinning pellets;

[0038] Step 2. The spinning pellets obtained in Step 1 are fully melted at 340°C through a screw extruder, quantitatively extruded through a hollow spinneret assembly, the screw speed is 5 r / min, and the glass fiber with an inner diameter of 1.8 mm is hollow woven tube, the winding speed is 7m / min, the spinning melt is solidified in an air bath, cooled and solidified in a coagulation bath to obtain a nascent hollow fiber membrane. The 80cm membrane filaments were intercepted and held in a stretching machine at 230 ℃. After the fixed-length treatment for 3 hours, the fixed-length s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| High temperature resistance | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com