Surface treatment solution composition for ternary hot-dip galvanized alloy steel sheet imparting excellent blackening resistance and alkali resistance, ternary hot-dip galvanized alloy steel sheet surface-treated with same, and method for manufacturing same

A surface treatment and hot-dip galvanizing technology, which is applied to the surface coating liquid device, hot-dip galvanizing process, surface pretreatment, etc., can solve the problem of poor blackening resistance, reduced corrosion resistance, and inability to suppress blackening, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

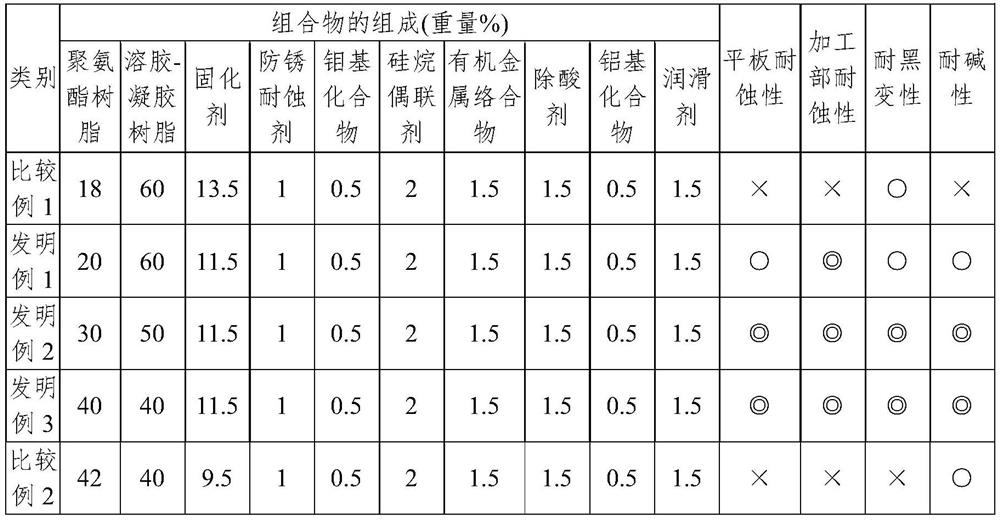

[0134] Example 1: Changes in Physical Properties According to Water-Soluble Polyurethane Resin Content

[0135] Based on the content shown in Table 1 with respect to 100% by weight of solids, a cationic polyurethane resin having a hydroxyl value of 120 mgKOH / g and a weight-average molecular weight of 3000 as a polyester polyol as a water-soluble polyurethane resin, three kinds of silane Compound crosslinking of silane-based sol-gel resins using methyltriethoxysilane, 3-glycidoxypropyltrimethoxysilane and N-(2-aminoethyl)-3-aminopropyl Polymer of triethoxysilane, melamine curing agent (CYMEL 303) as curing agent, vanadium-based rust inhibitor as anti-rust and corrosion-resistant agent, molybdenum sulfide as molybdenum-based compound, 2- Perfluorooctylethyltrimethoxysilane, titanium-based compound as an organometallic complex, oxazoline-based acid scavenger as an acid scavenger, aluminum nitride as an aluminum-based compound, polyethylene as a lubricant - Polytetrafluoroethylen...

Embodiment 2

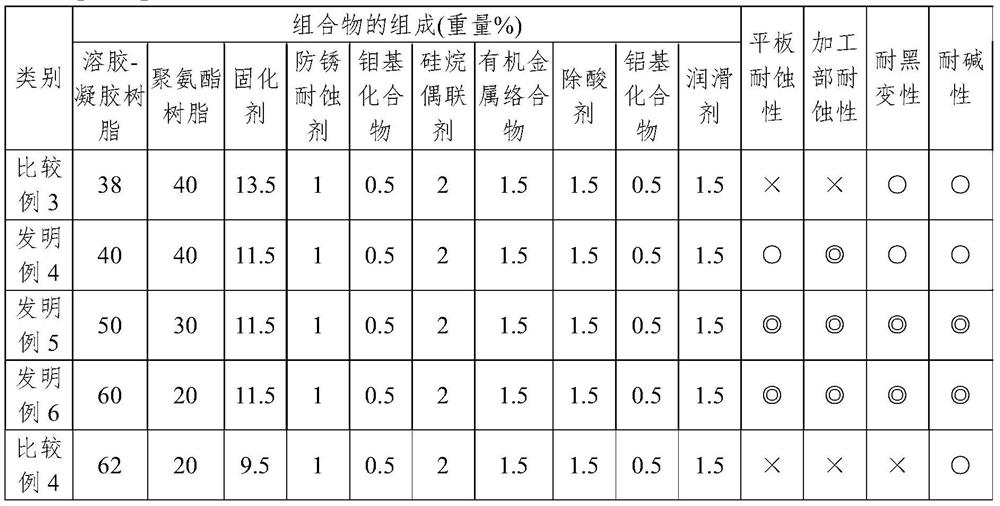

[0143] Example 2: Variation of physical properties according to content of silane-based sol-gel resin

[0144] Based on 100 parts by weight of solids, according to the content shown in Table 2, using the same composition as in Example 1, the solids were mixed with 81.4% by weight of water and 3.4% by weight of ethanol as a solvent, Thus, a surface treatment solution composition was prepared.

[0145] Using the surface treatment solution composition, a test piece was produced by the same method as in Example 1, and for the hot-dip galvanized steel sheet with a coating as described above, flat plate corrosion resistance and processed part corrosion resistance were evaluated. , blackening resistance and alkali resistance, and the results are shown in Table 2.

[0146] [Table 2]

[0147]

[0148] *The content of the composition is based on 15% by weight of solids.

[0149] As shown in the above-mentioned Table 2, when the content of the silane-based sol-gel resin satisfies t...

Embodiment 3

[0151] Example 3: Changes in physical properties according to curing agent content

[0152] Based on 100 parts by weight of solids, according to the content shown in Table 3, using the same composition as in Example 1, the solids were mixed with 81.4% by weight of water and 3.4% by weight of ethanol as a solvent, Thus, a surface treatment solution composition was prepared.

[0153] Using the surface treatment solution composition, a test piece was produced by the same method as in Example 1.

[0154] Table 3 shows the results of evaluating flat plate corrosion resistance, processed portion corrosion resistance, blackening resistance, alkali resistance, and solution stability for the coated hot-dip galvanized steel sheets as described above.

[0155] [table 3]

[0156]

[0157] *The content of the composition is based on 15% by weight of solids.

[0158] As shown in Table 3, all physical properties of Invention Examples 7 to 9 in which the content of the melamine curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com