Coagulant for NBR latex coagulation and NBR latex coagulation method

A coagulant and latex technology, which is applied in the field of coagulant and NBR latex coagulation, can solve the problems that affect the product's oil resistance, mechanical performance decline, and slow layering and precipitation, and achieve the effect of low price, low cost and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Add 1.8 liters of deoxidized and deionized water to a 5-liter polymerization kettle under nitrogen protection, then add 60 mL of 15.6% by weight potassium oleate and 40 mL of 25% by weight disproportionated rosin potassium in the polymerization sight glass, containing 0.05 mol iron / L 15mL of mixed aqueous solution of EDTA iron sodium salt and 0.025mol / L EDTA sodium tetraacetate, 13.5% by weight of sodium methylene dinaphthalene sulfonate aqueous solution 18mL, mass concentration of 10% sodium carbonate, sodium phosphate and chloride Add 10, 12 and 15 mL of potassium aqueous solution, 3 mL of 1.4% by weight sodium dithionite aqueous solution, and 10 mL of 6.2% by weight aqueous solution of dithionite, then press the above-mentioned additives into the polymerization kettle with nitrogen gas, start stirring, and then feed 5°C circulating cooling water, and then 260g of acrylonitrile dissolved in 5.8mL of dodecyl mercaptan was injected into a 860mL butadiene metering tank wi...

Embodiment 1

[0036] In the coagulant preparation tank, press soft water: ethanol: calcium chloride: sulfuric acid=444:30:25:1 (mass ratio) ratio to be formulated into coagulant aqueous solution, wherein in the solution, contain calcium chloride 5.2% by weight, ethanol 6.1% by weight %, pH value = 5~6, and then use an acid-resistant pump to continuously and evenly inject into the 5-liter coagulation tank with stirring at a flow rate of 0.5L / min until it is full, and the coagulant after filling passes through the overflow port on the tank Return to the preparation tank through the vibrating filter screen to form a coagulant circulation system. At this time, the NBR latex prepared in Example 1 is continuously and evenly injected into the bottom of the coagulation tank at a flow rate of 0.125 L / min through the latex pump, and the latex is stirred at 23 ° C, 130 rpm under the action of a coagulant, and after 24 seconds White NBR rubber particles with a diameter of 5-30mm emerge from the liquid ...

Embodiment 2

[0041] The relevant conditions in the implementation 1 remain unchanged, only the coagulant is changed into an aqueous coagulant solution in the ratio of soft water: ethanol: alum: sulfuric acid=264:41:28:1 (mass ratio), wherein the solution contains alum 8.3% by weight, 12.3% by weight of ethanol, pH = 5 to 5.5.

[0042] Results During the dehydration process, the pH value of the water extruded by the mill was 6-7;

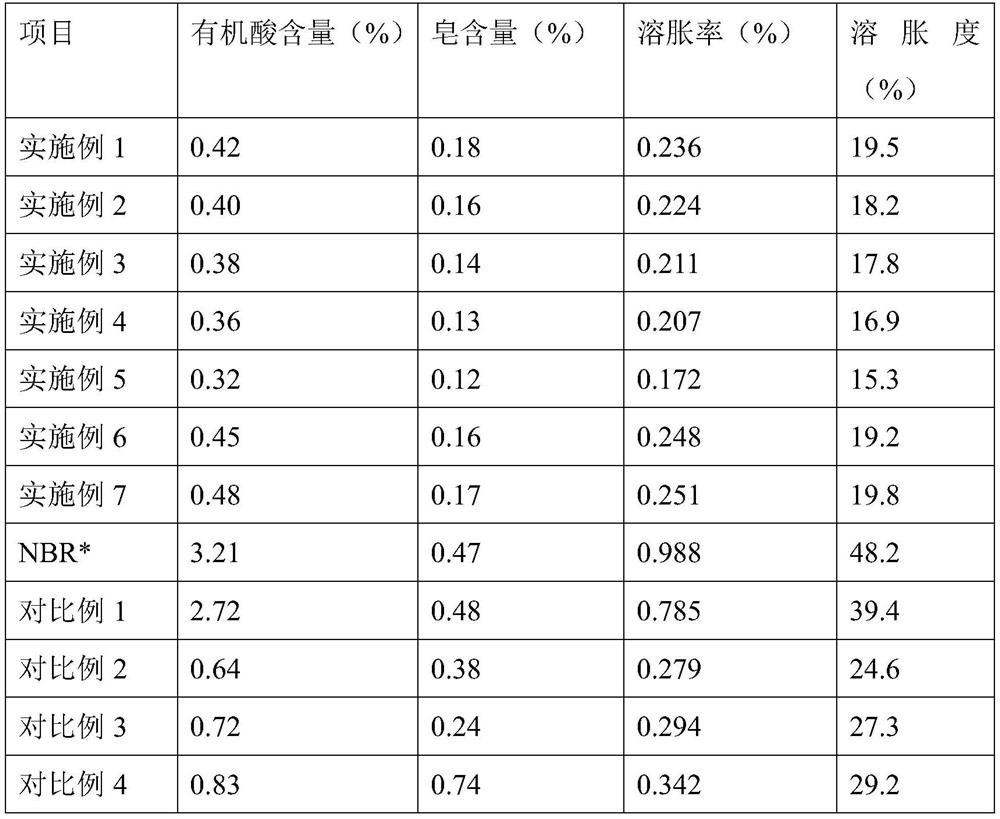

[0043] The 300% modulus stress of NBR vulcanized rubber was measured to be 11.6 MPa, the breaking strength was 26.4 MPa, and the breaking elongation was 462%; the organic acid content in the raw rubber was 0.40% by weight, and the soap content was 0.16% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com