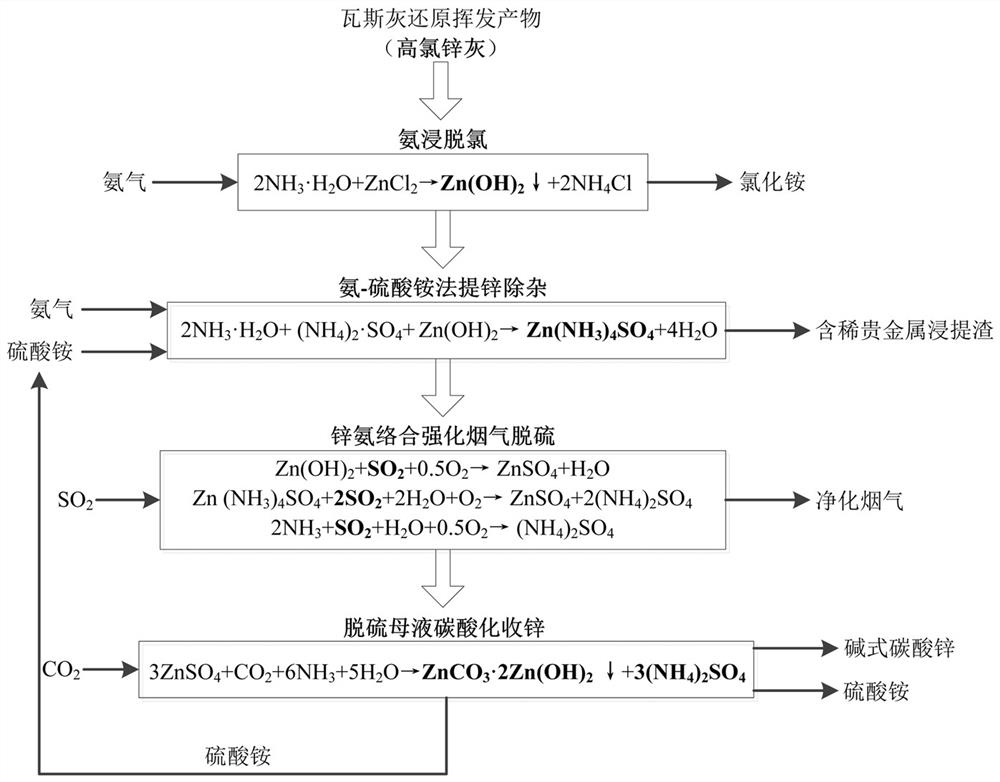

Process for flue gas desulfurization and carbon sequestration by coupling high-chlorine zinc ash ammonia-ammonium sulfate method efficient zinc extraction with ore pulp method

A high-chloride zinc and flue gas technology, which is applied in the direction of ammonium chloride, zinc compounds, and process efficiency improvement, can solve the problems of secondary pollution in the separation process, difficulty in separation and purification, and complex components of blast furnace gas ash. Low-cost and high-efficiency recovery, and the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Firstly, the zinc leaching experiment was carried out, and 150 mL of a mixture of ammonia water, ammonium sulfate and zinc oxide in different proportions was prepared and placed in a beaker; a constant temperature water bath magnetic stirring pot was set, T=25 °C, r=700 r / min; When the temperature of the water bath pot rises to 25°C, start the magnetic stirring for t=60 min, and then vacuum filter to remove the slag to obtain the zinc-ammonia complex solution, as shown in Table 3;

[0046] Table 3 Zinc leaching rate of mixed solutions at different ratios

[0047] serial number (NH 4 ) 2 SO 4 / g

[0048] It can be seen from the data that the third group c(NH 3 ) : c(NH 4 ) 2 SO 4 ) = 4.5:1; c(NH 3 ):c(ZnO)=33:1; c((NH 4 ) 2 SO 4 ) : c(ZnO) = 7.4:1. The leaching rate of zinc oxide in the mixed solution under this condition is more than 95%, which meets the requirement of zinc recovery.

Embodiment 2

[0050] The high-chloride zinc ash to be treated includes the following components: Pb2.75%, Zn54.80%, Fe3.47%, Cl10.92%, Cd0.48%, S1.10%;

[0051] (1) Add industrial ammonia water to the high-chloride zinc ash to be treated at a solid-to-liquid ratio of 1 (g): 3 (ml), and mix thoroughly at room temperature for ammonia leaching dechlorination. The chlorine in the zinc ash is equal to that of ammonium chloride Form is removed, and then solid-liquid separation is carried out to obtain filter residue and filtrate, and the obtained filtrate can be used as a by-product after further treatment; the removal rate of chlorine in high-chloride zinc ash here is 98.9%;

[0052] (2) add ammoniacal liquor and ammonium sulfate solution in step (1) gained filter residue, described ammoniacal liquor is the ammoniacal liquor of 28%, the add-on of described ammoniacal liquor and ammonium sulfate solution is to make ammonia, ammonium sulfate, zinc in the gained mixed liquor The molar concentration...

Embodiment 3

[0056] The high-chloride zinc ash to be treated includes the following components: Pb2.76%, Zn57.00%, Fe2.21%, Cl11.13%, Cd0.26%, S0.62%;

[0057] (1) Add 3% ammonia water to the high-chloride zinc ash to be treated according to the solid-to-liquid ratio of 1 (g): 6 (ml), mix well for ammonia leaching dechlorination, and the chlorine in the zinc ash is in the form of ammonium chloride Removal is carried out, followed by solid-liquid separation to obtain filter residue and filtrate, and the resulting filtrate is used as a by-product after further treatment; the ammonia leaching temperature is 40 °C; the removal rate of chlorine in high-chloride zinc ash here is 98.0%;

[0058] (2) add 20% ammoniacal liquor and ammonium sulfate solution in step (1) gained filter residue, the add-on of described ammoniacal liquor and ammonium sulfate solution is to make the molar concentration ratio of ammonia, ammonium sulfate, zinc in the gained mixed solution be 38: 10:1, the obtained mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com