Method and system for growing ultra-wide bandgap semiconductor material by ultraviolet-assisted MOCVD (Metal Organic Chemical Vapor Deposition)

A wide-bandgap semiconductor and semiconductor technology, applied in semiconductor/solid-state device manufacturing, metal material coating process, coating, etc., can solve problems such as decomposition or oxidation, enhanced optical absorption of materials, and reduced lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

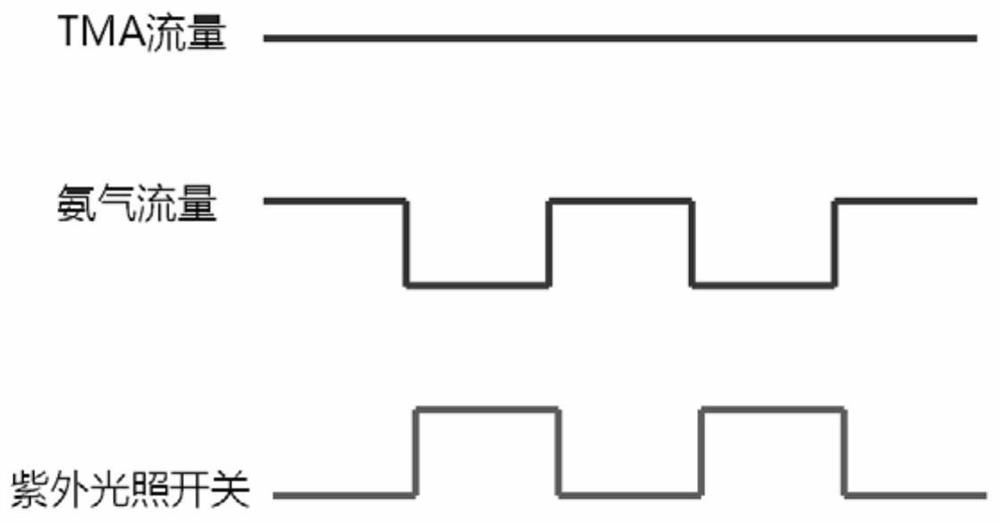

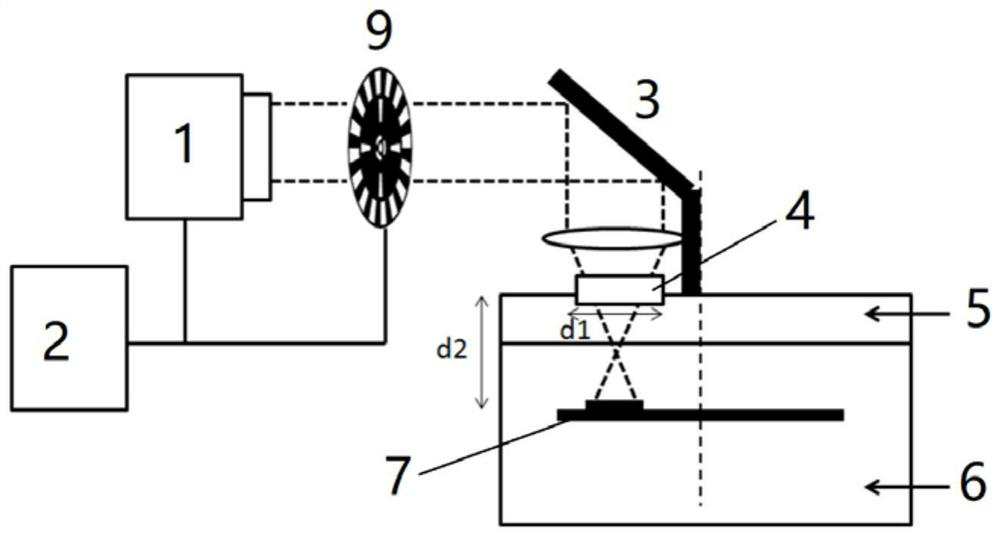

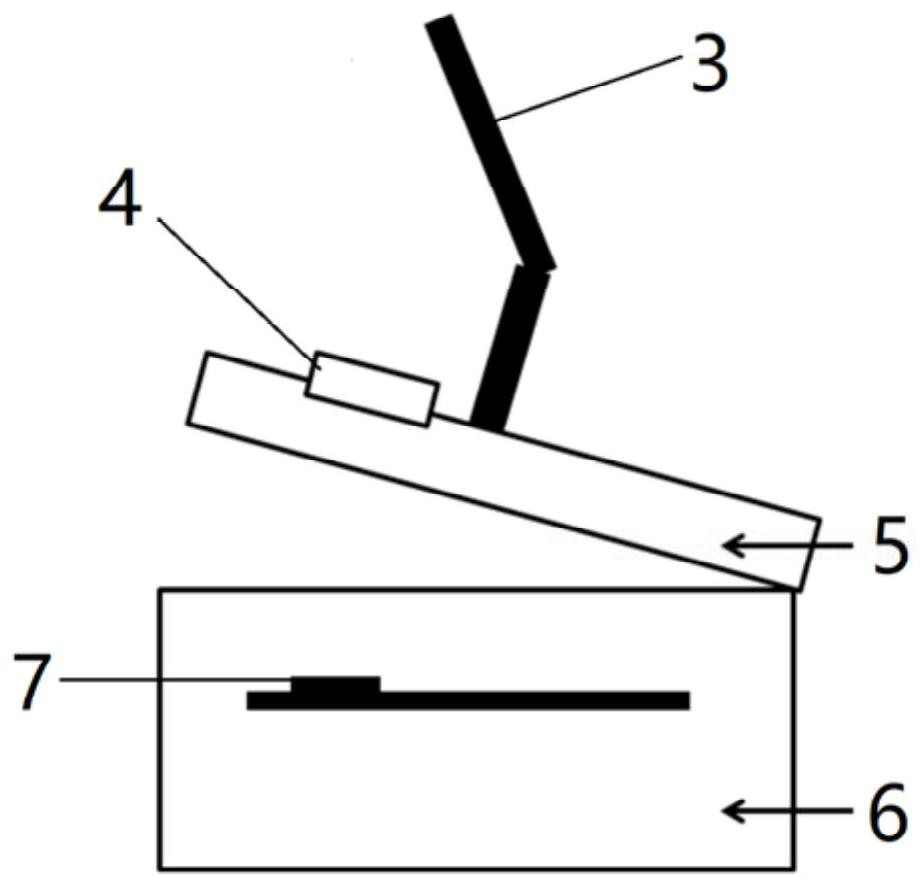

[0078] The process conditions for growing AlN epitaxial film by using this system include: trimethylaluminum (TMA) and ammonia gas are used as gas sources. The carrier gas is H 2 The flow rates of ammonia gas and carrier gas are 1slm and 10slm respectively; the V / III ratio of epitaxial growth is 200; the growth temperature is 1200°C, TMA is fed continuously, and ammonia gas is fed at intervals in a pulsed manner, with an interval of 10s. The duty ratio is 70%; during the interval time when the ammonia gas is not introduced, the surface of the sample is irradiated with ultraviolet light, and a 3 μm AlN epitaxial film is grown.

[0079] In Comparative Example 1 of this embodiment, the method for growing an ultra-wide bandgap semiconductor material is basically the same as that of this embodiment, except that ultraviolet light pulse irradiation is not used.

[0080] In Comparative Example 2 of this embodiment, the method for growing an ultra-wide bandgap semiconductor material i...

Embodiment 2

[0084] Utilizing the technical solutions of the above embodiments of the present application can effectively improve the crystal quality of ultra-wide bandgap semiconductor materials, increase their carrier concentration and electrical breakdown level, and facilitate the growth of thicker ultra-wide bandgap semiconductor materials and ensure It is uniform and complete, and can reduce the difficulty and energy consumption of its manufacturing process.

[0085] It should be noted that in this article, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that there is a relationship between these entities or operations. There is no such actual relationship or order between them. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article, or apparatus comprising a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com