Preparation method of tellurium-ene saturable absorber and high-energy laser application of tellurium-ene saturable absorber

A saturable absorption, high-energy technology, used in the field of lasers, to achieve good environmental stability, significant effects, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of tellurene-based saturable absorber, the concrete steps are as follows:

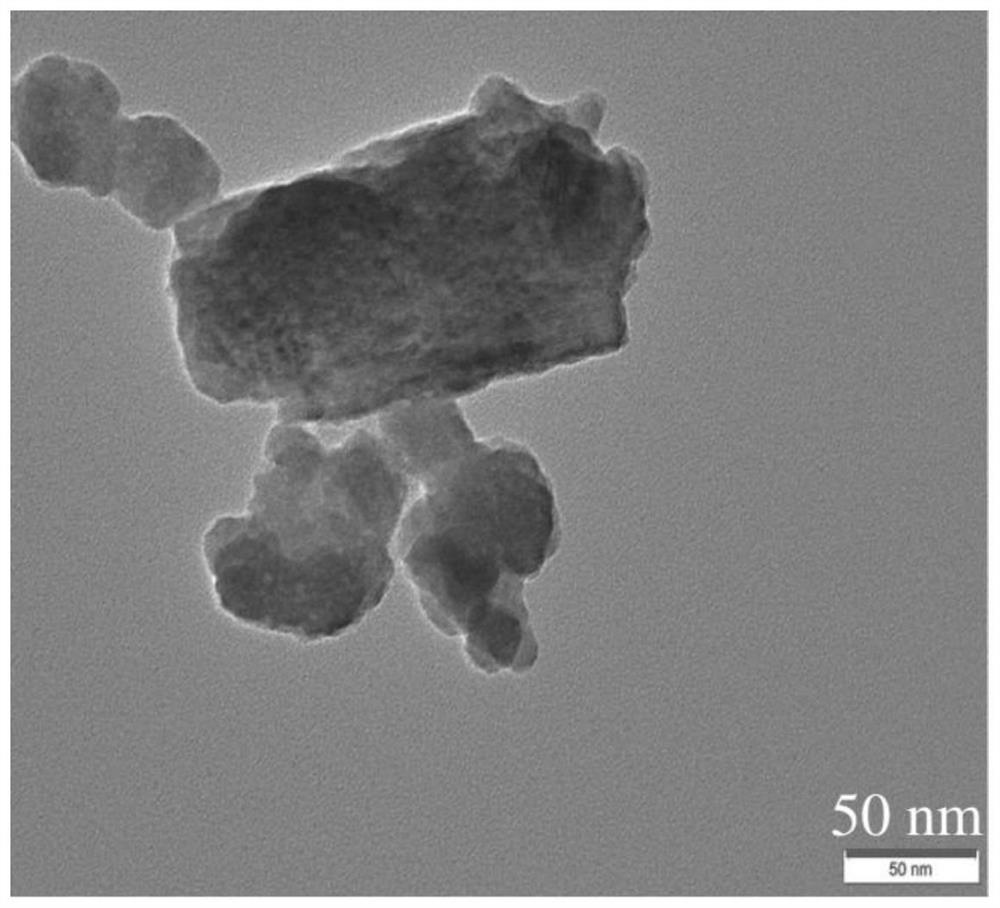

[0036] Step 1: Peel off the tellurium powder from the bulk tellurium, add it to 50ml of ethanol and soak it for about 48 hours. Then, the tellurene-ethanol solution was sonicated for 8 hours to further prepare the tellurene nanosheet dispersion. The solution was centrifuged at 2000 rpm for 30 minutes to remove the precipitate. At this point, a multi-layer tellurene nanosheet dispersion was successfully prepared;

[0037] Step 2: Mix the tellurene nanosheet dispersion with the 5 wt% polyvinyl alcohol solution in a volume ratio of 1:1. Put the mixed solution into an ultrasonic cleaner for ultrasonic treatment for 6 hours to obtain a uniform tellurene-polyvinyl alcohol solution;

[0038] Step 3: Fix a tapered optical fiber (the length of the tapered area and the diameter of the optical fiber are about 1.6 mm and 18 μm, respectively) on the glass, and apply 120 μl of ...

Embodiment 2

[0041] A mode-locked fiber laser based on a tellurene saturable absorber, the specific scheme is as follows:

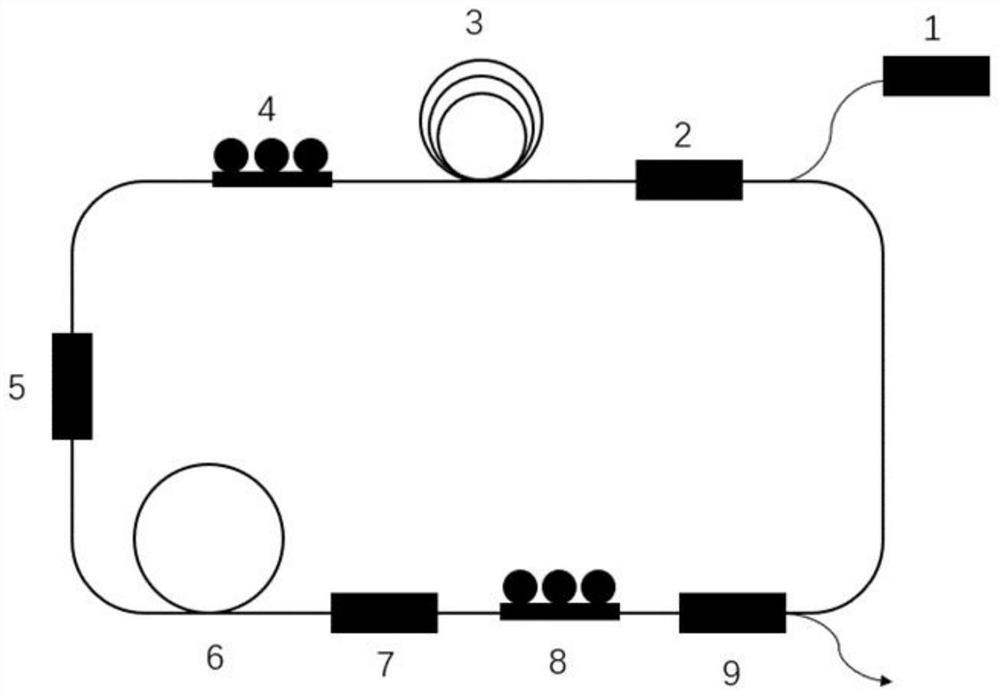

[0042] figure 2 Shown is a schematic diagram of the structure of the mode-locked fiber laser of the present invention. The mode-locked fiber laser includes a pump source 1 and a ring resonator, and the ring resonator consists of a wavelength division multiplexer 2, an erbium-doped fiber 3, a polarization controller 4, a polarization independent isolator 5, a single-mode fiber 6, It consists of a saturable absorber 7 , a polarization controller 2 8 and an output coupler 9 .

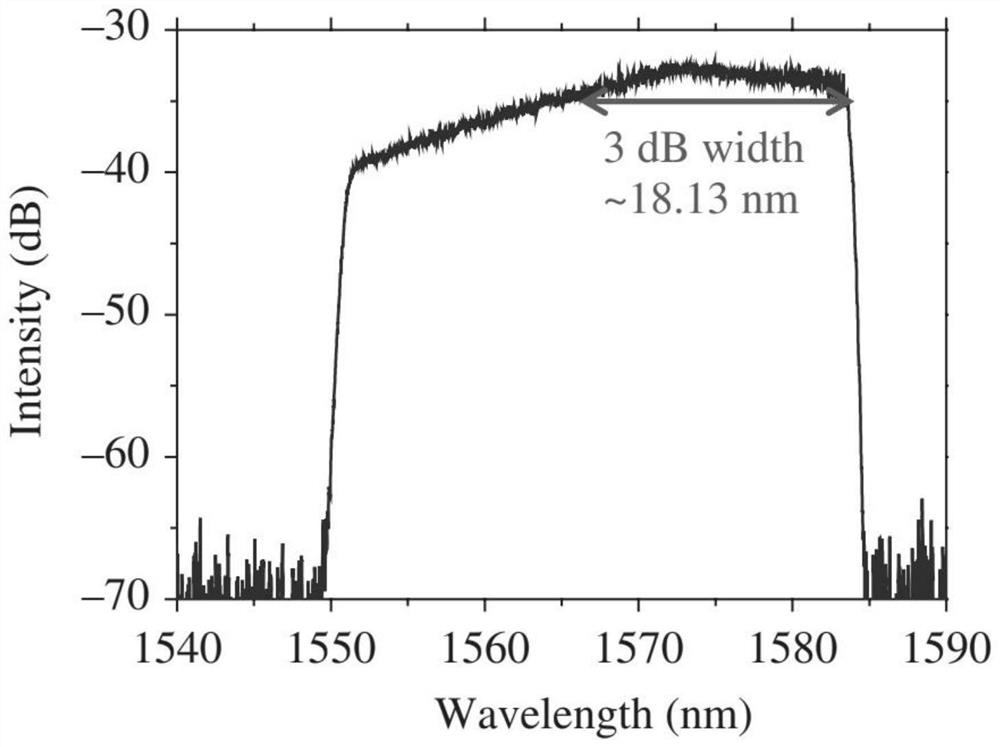

[0043] Wherein, the pump source 1 is a laser diode, and the center wavelength of the pump source is 976 nm; the wavelength division multiplexer 2 includes a 980 nm input end, a 1550 nm input end and an output end, and the pigtail is an ordinary single-mode fiber; The length of the erbium-doped fiber 3 is 10.3 m; the output coupler 9 includes a 10% output end and a 90% output end, wherein the 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com