Atomic oxygen-resistant polyimide nanofiber membrane as well as preparation method and application thereof

A technology of nanofiber membrane and oxypolyimide, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problem of uneven dispersion of metals, metal compounds or non-metal compounds, and the influence of PI material application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides the preparation method of the atomic oxygen-resistant polyimide nanofiber membrane according to the above technical solution, comprising the following steps:

[0056] The aromatic diamine monomer, the cage-containing polysilsesquioxane diamine monomer, the aromatic dianhydride monomer and the aprotic strong polar solvent are mixed, and a polymerization reaction is carried out to obtain a polyamic acid solution;

[0057] The aromatic diamine monomer is 2,5-bis[(4-aminophenoxy)phenyl]diphenylphosphine oxide or 4,4'-diaminodiphenyl ether; the aromatic dianhydride monolayer The monomer is pyromellitic dianhydride or 3,3',4,4'-biphthalic dianhydride; the cage-containing polysilsesquioxane diamine monomer is N-[(heptaisobutyl -POSS) propyl]-3,5-diaminobenzamide;

[0058] Electrospinning the polyamic acid solution to obtain a polyamic acid nanofiber membrane;

[0059] The polyamic acid nanofiber film is subjected to an imidization reaction...

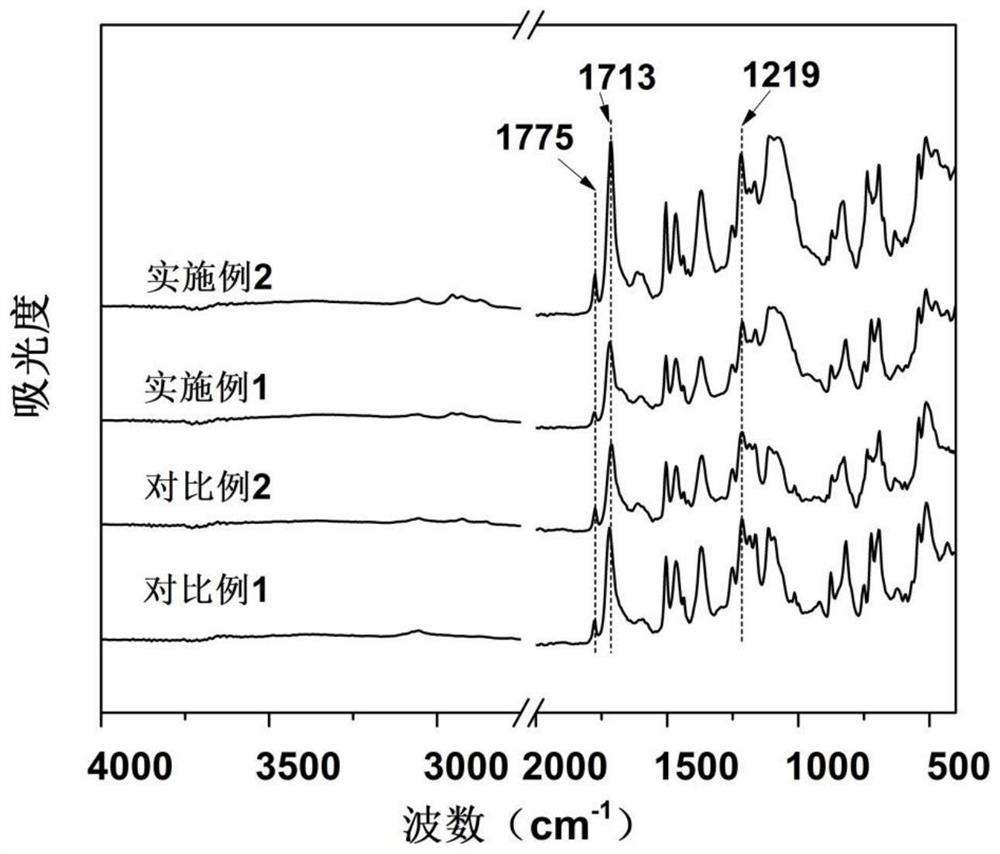

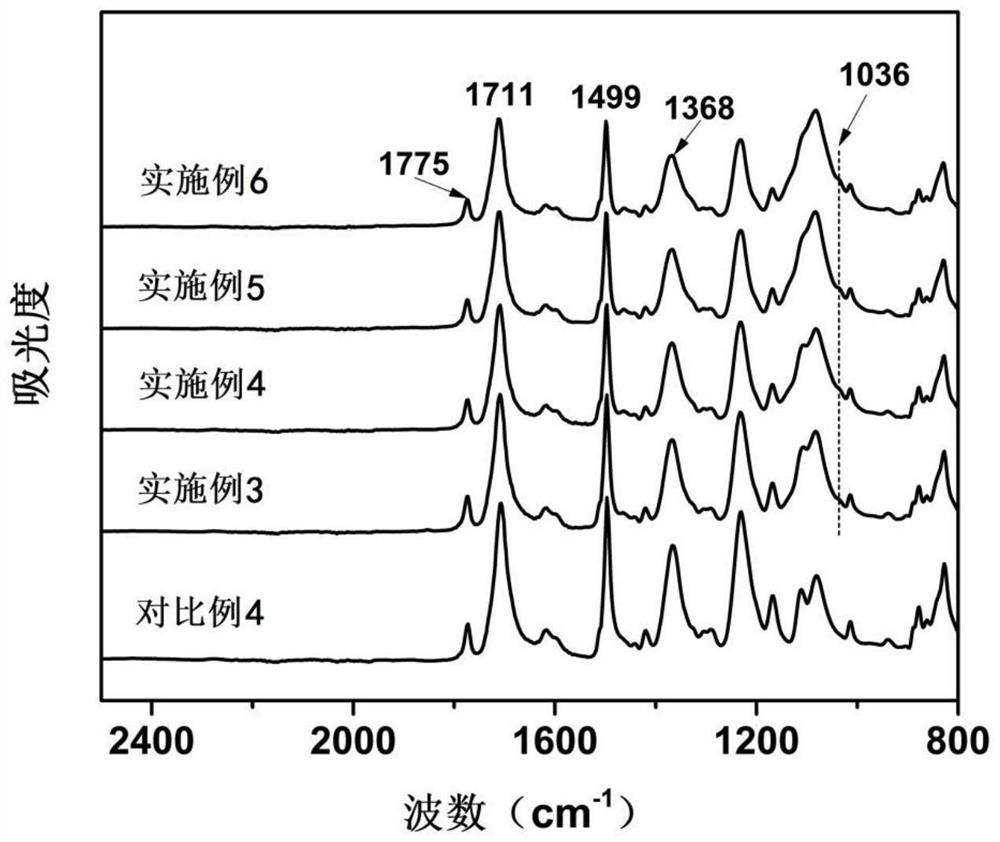

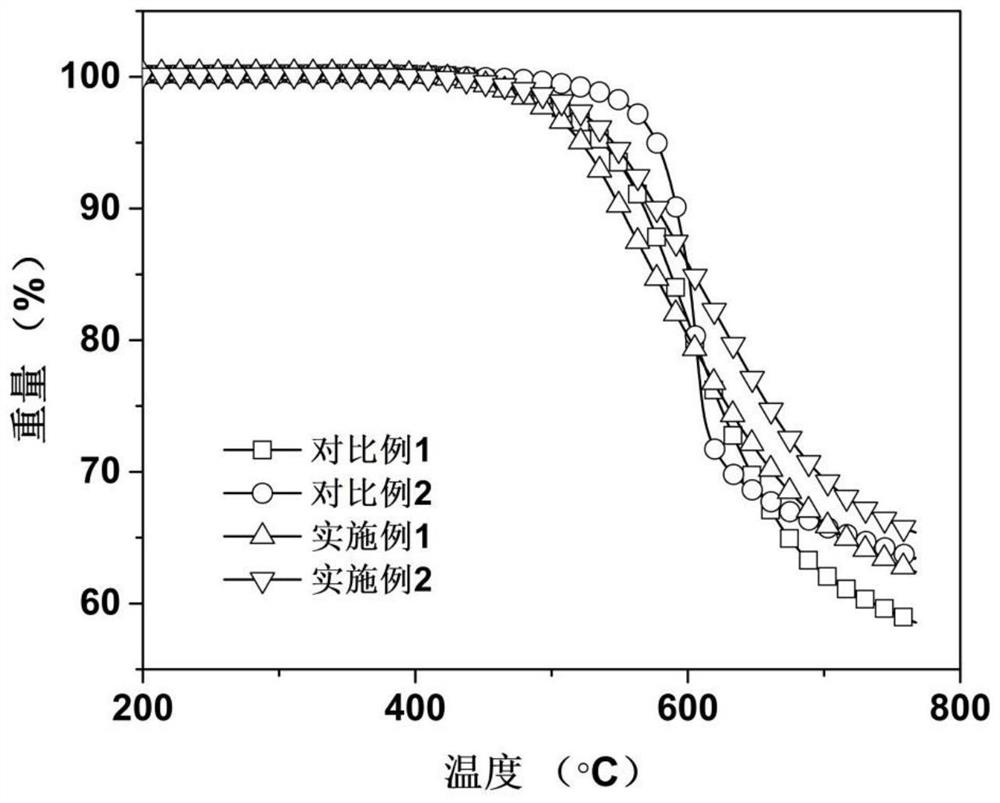

Embodiment 1

[0091] At room temperature, 19.0325 g (38.65 mmol) BADPO, 7.2588 g (7.196 mmol) DA-POSS and 120 g DMAc (N,N-dimethylethyl acetate) were added to a 500 mL three-necked flask equipped with a mechanical stirrer, a cold water bath and a nitrogen inlet. amide), stir for 1h until the solid dissolves to form a homogeneous solution, add 10g (45.846mmol) PMDA and 85.7g DMAc to the above solution, stir for 1h until the solid dissolves to form a homogeneous solution, and then carry out the polymerization reaction at 5°C for 24h in a nitrogen atmosphere, the reaction During the process, stirring was performed to obtain a PAA solution with a solid content of 15 wt.%;

[0092] Add DMAc to adjust the viscosity of the PAA solution to 4000mPa·s, then add the PAA solution into a 5mL syringe equipped with a stainless steel needle spinneret with an inner diameter of 0.50mm, apply a positive voltage of 15kV to the syringe and receiver and - The negative voltage of 2kV, the distance between the rec...

Embodiment 2

[0095] At room temperature, 13.8304 g (28.082 mmol) BADPO, 5.9576 g (5.906 mmol) DA-POSS and 100 g DMAc (N,N-dimethylethyl acetate) were added to a 500 mL three-necked flask equipped with a mechanical stirrer, a cold water bath and a nitrogen inlet. amide), stir for 1h until the solid dissolves to form a homogeneous solution, add 10g (33.988mmol) BPDA and 68.8g DMAc to the above solution, stir for 1h until the solid dissolves to form a homogeneous solution, and then conduct a polymerization reaction at 5°C for 24h in a nitrogen environment, the reaction During the process, stirring was performed to obtain a PAA solution with a solid content of 15 wt.%;

[0096] The remaining steps are the same as those in Example 1, to obtain atomic oxygen-resistant polyimide nanofiber membrane (m=83, n=17, DA-POSS accounts for 20% of the total mass of BPDA, BADPO and DA-POSS), polyimide The structural formula is

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com