Preparation method of nickel cobalt lithium manganate standard sample

A technology of nickel-cobalt lithium manganate and standard samples, which is applied in the preparation of test samples, material weighing, material excitation analysis, etc., can solve the problems of uncontrollable preparation and low content of impurity elements, and ensure uniformity And stability, good uniformity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of nickel cobalt lithium manganate standard sample of the present invention comprises the following steps:

[0031] 1) According to the design of the proportion of ingredients, take by weighing an appropriate amount of nickel nitrate, cobalt nitrate, manganese nitrate, magnesium nitrate, calcium nitrate, copper nitrate, ferric nitrate, zinc nitrate and zirconium nitrate, add them into deionized water and stir, and the concentration is as follows: 1.0mol / L~2.0mol / L mixed solution;

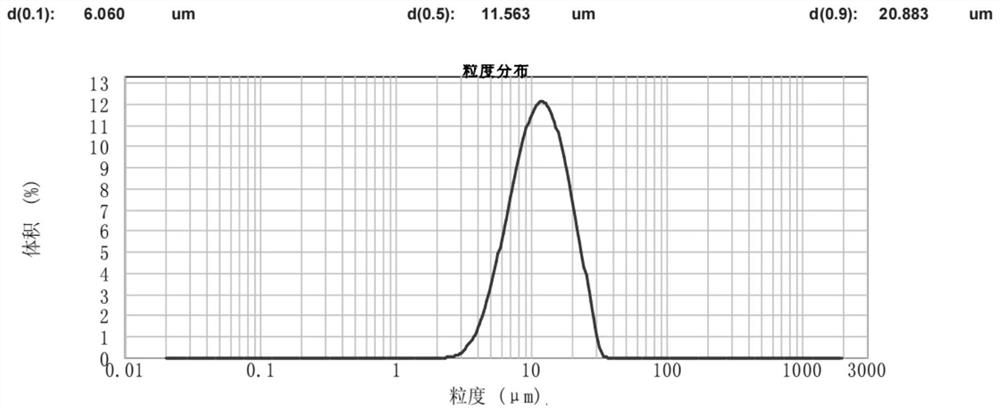

[0032] Taking zirconium-doped 811 nickel cobalt lithium manganate as the matrix, the composition ratio of the reaction raw materials can be referred to in Table 1; the ratio in the table is the mass percentage of the metal element, and the oxygen content is the balance;

[0033] 2) Add an appropriate amount of silicon-containing solution to the sodium hydroxide solution with a concentration of 1.0 mol / L to 5.0 mol / L, and stir evenly; the medium of the silicon-containing...

Embodiment 1

[0039] 1) According to the composition ratio design, weigh an appropriate amount of analytically pure nickel nitrate, cobalt nitrate, manganese nitrate, magnesium nitrate, calcium nitrate, copper nitrate, ferric nitrate, zinc nitrate and zirconium nitrate, add them to deionized water, stir, and mix. into a 1.0 mol / L mixed metal ion solution; the mass percentage of metal elements in the nickel cobalt lithium manganate matrix is shown in Table 2. Oxygen element content is the balance. The mass percentage content of each raw material is nickel nitrate 77.84%, cobalt nitrate 10.02%, manganese nitrate 11.79%, magnesium nitrate 0.066%, calcium nitrate 0.044%, copper nitrate 0.016%, iron nitrate 0.022%, zinc nitrate 0.022% and zirconium nitrate 0.18%.

[0040] Table 2 Composition ratio table (wt%) of reaction raw materials in Example 1

[0041]

[0042]

[0043] 2) 50 mL of sodium silicate solution containing silicon concentration of 10000 μg / mL was added to 500 mL of 2.0 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com