Synchronous induced synthesis method of arabinosidase and xylanase

An arabinosidase and xylanase technology, which is applied in the field of microbial culture in biochemistry, can solve the problem that key hydrolases cannot be efficiently and synergistically prepared, and achieve the effects of efficient preparation and improved hydrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of psyllium polysaccharide with different molecular weights comprises the following steps:

[0029] (1) The psyllium husk was mechanically pulverized, sieved through a 100-mesh sieve, and the solid-liquid ratio (g / mL) was 1:20, extracted for 12 hours at 170 rpm in a constant temperature shaker at 50°C, and then centrifuged at 10,000 rpm. Collect the supernatant for 10 min, and the supernatant is the psyllium polysaccharide mixed solution;

[0030] (2) Take the psyllium polysaccharide mixed solution obtained in step (1), add absolute ethanol under constant stirring, control the ethanol concentration (volume concentration) in the system to be 15%, and separate the mixed solution through solid-liquid separation to obtain a supernatant 1 and the precipitation, the precipitation is washed 3 times in the ethanolic solution of 15% (volume concentration), and freeze-drying is the psyllium polysaccharide component 1, and the average of the psyllium polysacch...

Embodiment 2

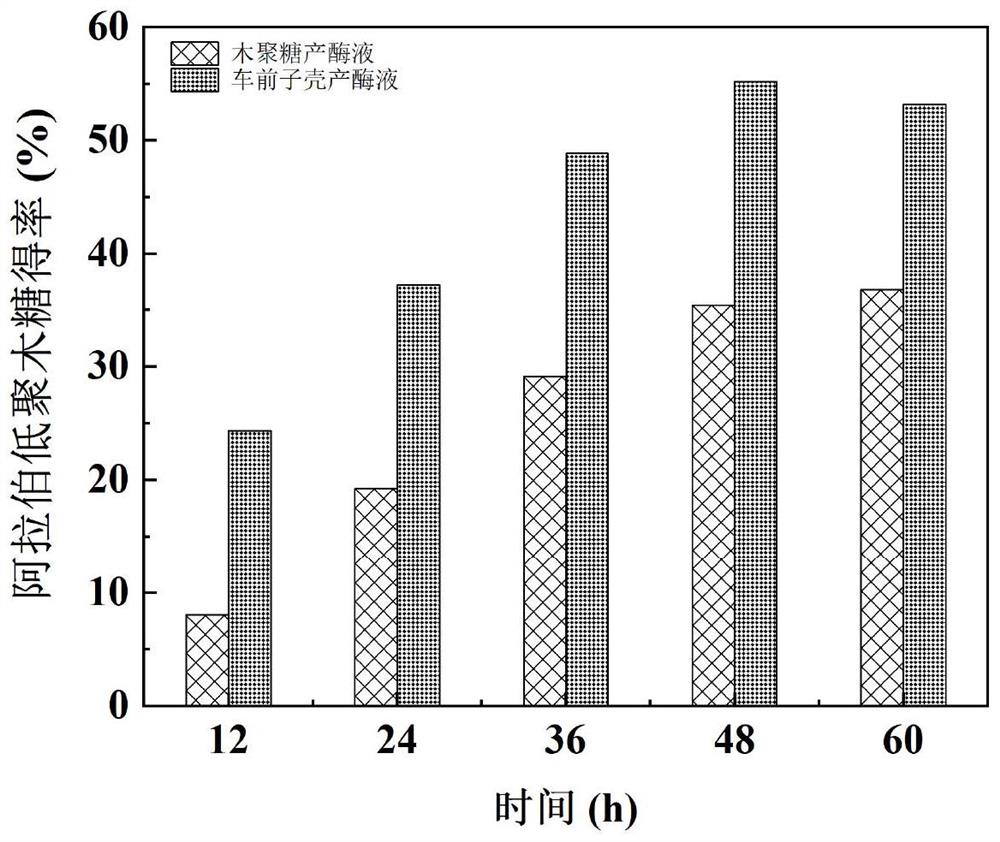

[0036] The fermentation enzyme production method using psyllium husk and psyllium polysaccharides with different molecular weights as inducing carbon sources mainly includes the following steps:

[0037] (1) Weigh 20.00g of psyllium husk and psyllium polysaccharide of different molecular weights (prepared in Example 1), 1.00g of glucose, 20.00g of potassium dihydrogen phosphate, 3.00g of urea, 1.50g of anhydrous magnesium sulfate, and sulfuric acid Ammonium 14.00g, Calcium Chloride 4.00g, FeSO 4 ·7H 2 O 5.00mg, MnSO 4 ·7H 2 O 1.60mg, ZnSO 4 ·7H 2 O 1.40mg, CoCl 2 After fully dissolving 2.00 mg in distilled water, add 50 mL of 1 mol / L citric acid buffer solution, dilute the volume to 1000 mL with distilled water, divide the enzyme production medium into packages and place it at 121 °C for sterilization for 15 min.

[0038] (2) The Trichoderma reesei spore suspension (the number of spores is 2.0×10 7 cfu / mL) according to 10% of the inoculum and mixed evenly with the enzy...

Embodiment 3

[0044] The fermentation enzyme production method for inducing carbon source after the psyllium husk and psyllium polysaccharides of different molecular weights are mixed, mainly includes the following steps:

[0045] (1) The psyllium husk is fully pulverized in a mechanical pulverizer with component I, component П, component III and component IV in the embodiment (1) respectively, in a mass ratio of 1:1, They are denoted as Mixed I, Mixed П, Mixed III and Mixed IV.

[0046] (2) take by weighing respectively mixed I, mixed П, mixed III and mixed IV (prepared in step (1)) 20.00g, glucose 1.00g, potassium dihydrogen phosphate 20.00g, urea 3.00g, anhydrous magnesium sulfate 1.50g, Ammonium sulfate 14.00g, calcium chloride 4.00g, FeSO 4 ·7H 2 O 5.00mg, MnSO 4 ·7H 2 O 1.60mg, ZnSO 4 ·7H 2 O 1.40mg, CoCl 2 After fully dissolving 2.00 mg in distilled water, add 50 mL of 1 mol / L citric acid buffer solution, dilute the volume to 1000 mL with distilled water, divide the enzyme pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com