Microbial preparation and aquaculture water purification method

A technology for microbial preparations and aquaculture water, which is applied in the field of water treatment to achieve the effects of high mechanical strength, rapid and efficient degradation, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

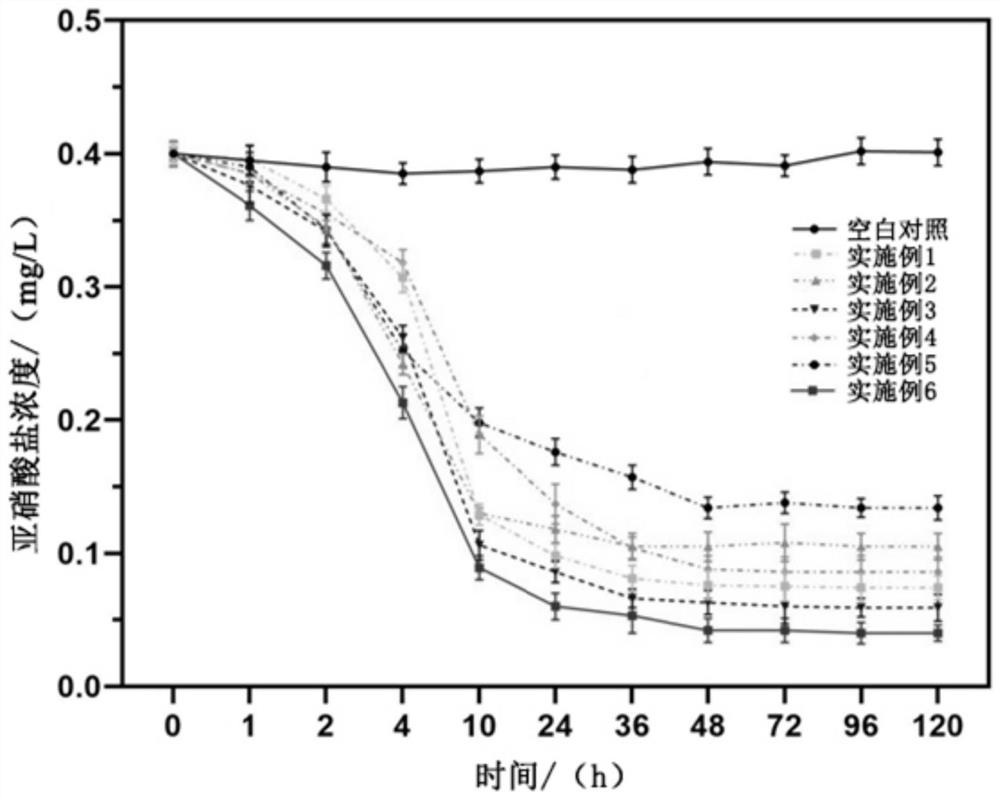

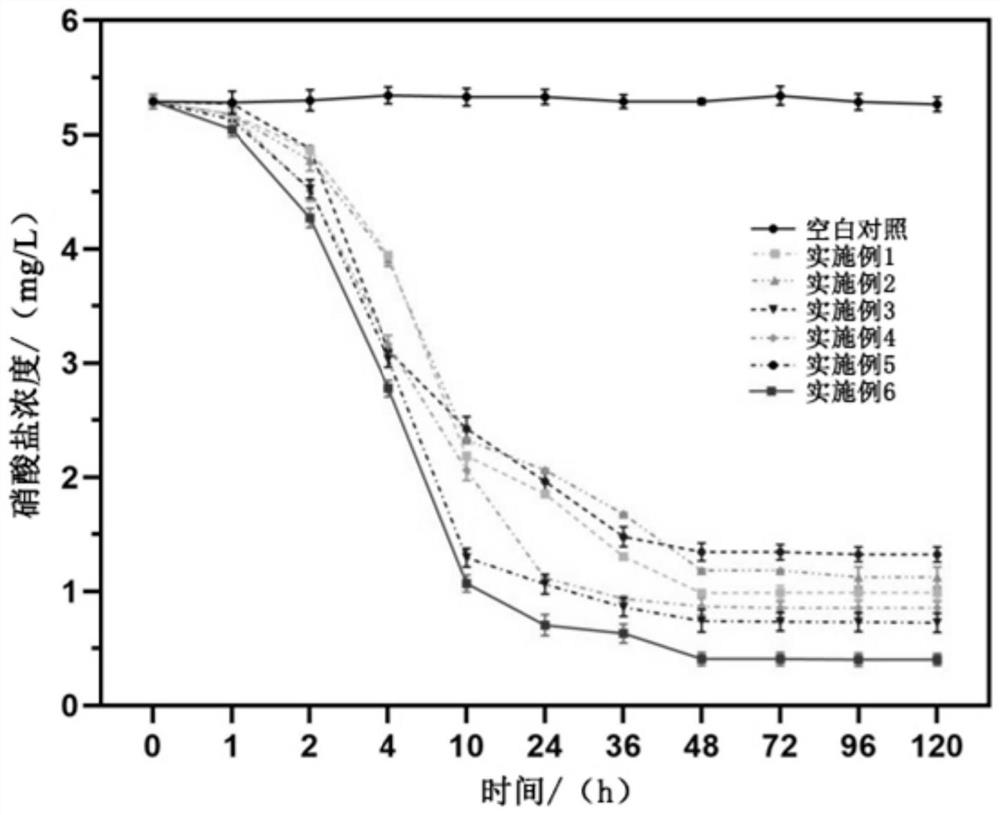

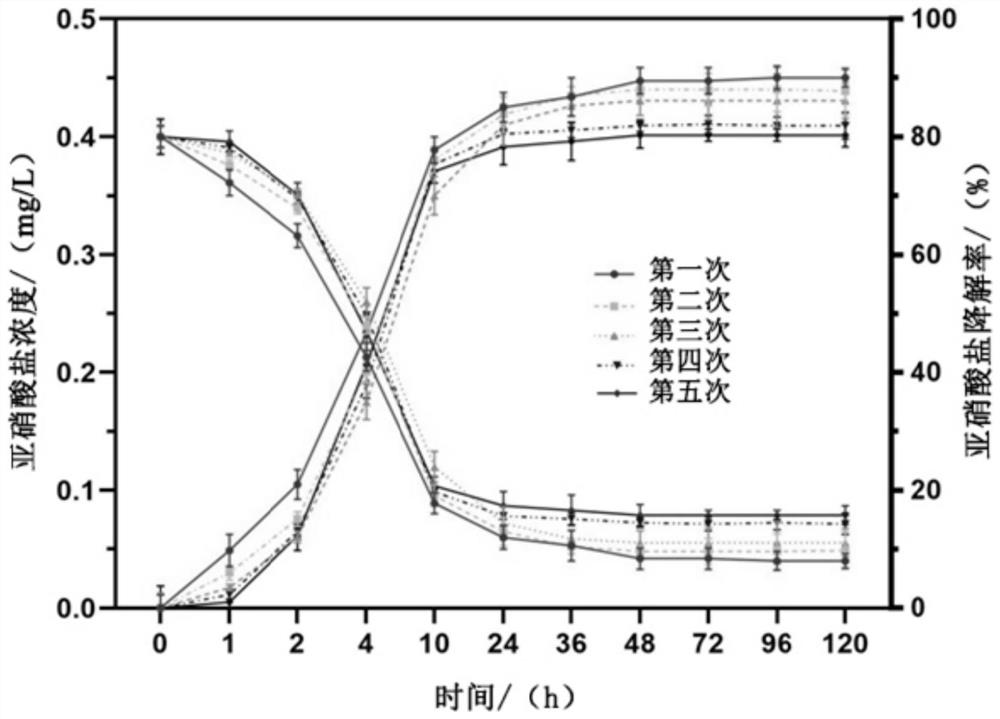

Examples

Embodiment 1

[0044] A microbial preparation, comprising a composite bacterial fixative and a ferrous stabilizer in a mass ratio of 2:1, the bacteria used in the composite bacterial fixative are Pseudomonas stutzeri (strain number CGMCC1.3184), rhamnose Lactobacillus (strain number is CGMCC1.533), Lactobacillus plantarum (strain number is CGMCC1.16089), Lactobacillus brevis (strain number is CGMCC1.3258), the above four kinds of bacteria can be purchased at the China General Microorganisms Collection and Management Center.

[0045] Wherein, the preparation method of composite bacterial fixative is as follows:

[0046] (1) Under stirring state, add sodium alginate and zeolite powder into distilled water in sequence in a mass ratio of 1:1, this adding method is beneficial to avoid agglomeration phenomenon, magnetic stirring 12h after adding sodium alginate and zeolite powder, Then add CaCO 3 Continue to stir evenly to obtain a premix, CaCO 3 The amount added is 0.1wt% based on the total mas...

Embodiment 2

[0067] The difference between Example 2 and Example 1 is that the ratio of four single bacterial bacterial suspensions in the composite bacterial solution is different when the composite bacterial fixative is prepared, and the composite bacterial solution of Example 2 is prepared according to the following method:

[0068] Pour the bacterial suspensions of Pseudomonas stutzeri, Lactobacillus rhamnosus, Lactobacillus plantarum and Lactobacillus brevis into a centrifuge tube at a mass ratio of 2:1:1:2, centrifuge at 10,000 rpm for 10 min, and rinse with sterile water. Mix it evenly, configure it into a bacterial suspension with uniform distribution, count the viable bacteria under the microscope, and the number of viable bacteria is 2.63 × 10 after calculation. 9 cfu / mL.

Embodiment 3

[0070] The difference between Example 3 and Example 1 is that the ratio of four single bacterial bacterial suspensions in the composite bacterial solution is different when the composite bacterial fixative is prepared, and the composite bacterial solution of Example 3 is prepared as follows:

[0071] Pour the bacterial suspensions of Pseudomonas stutzeri, Lactobacillus rhamnosus, Lactobacillus plantarum and Lactobacillus brevis into a centrifuge tube at a mass ratio of 2:1:2:1, centrifuge at 10,000 rpm for 10 min, and rinse with sterile water. Mix it evenly, configure it into a bacterial suspension with uniform distribution, count the viable bacteria under the microscope, and the number of viable bacteria is 2.33 × 10 after calculation. 9 cfu / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com