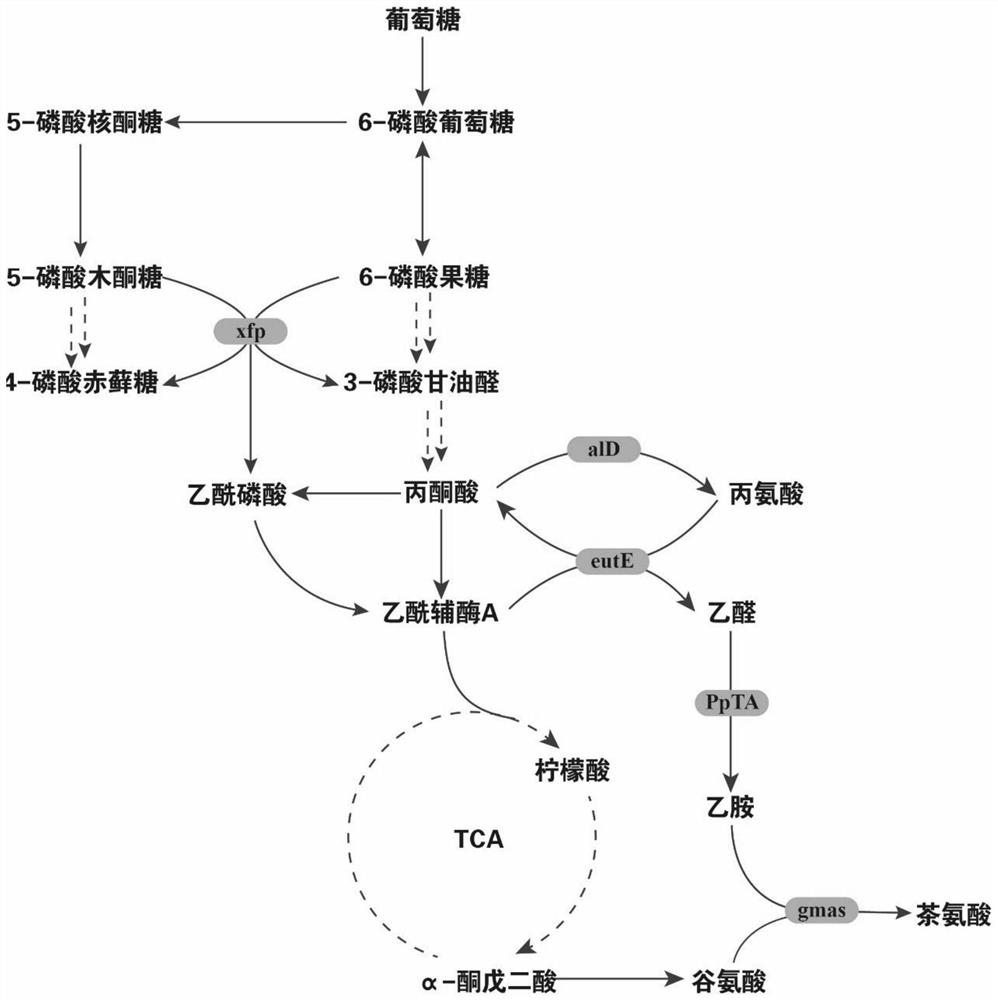

Genetically engineered bacterium for producing L-theanine by utilizing glucose de novo fermentation, method and application

A technology of genetically engineered bacteria and genetically engineered strains, applied in the field of genetic engineering, can solve the problems of weakened ATP regeneration, harmful external environment, and low yield of tea theanine, so as to avoid damage to the human body, reduce equipment occupancy, and simplify The effect of the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

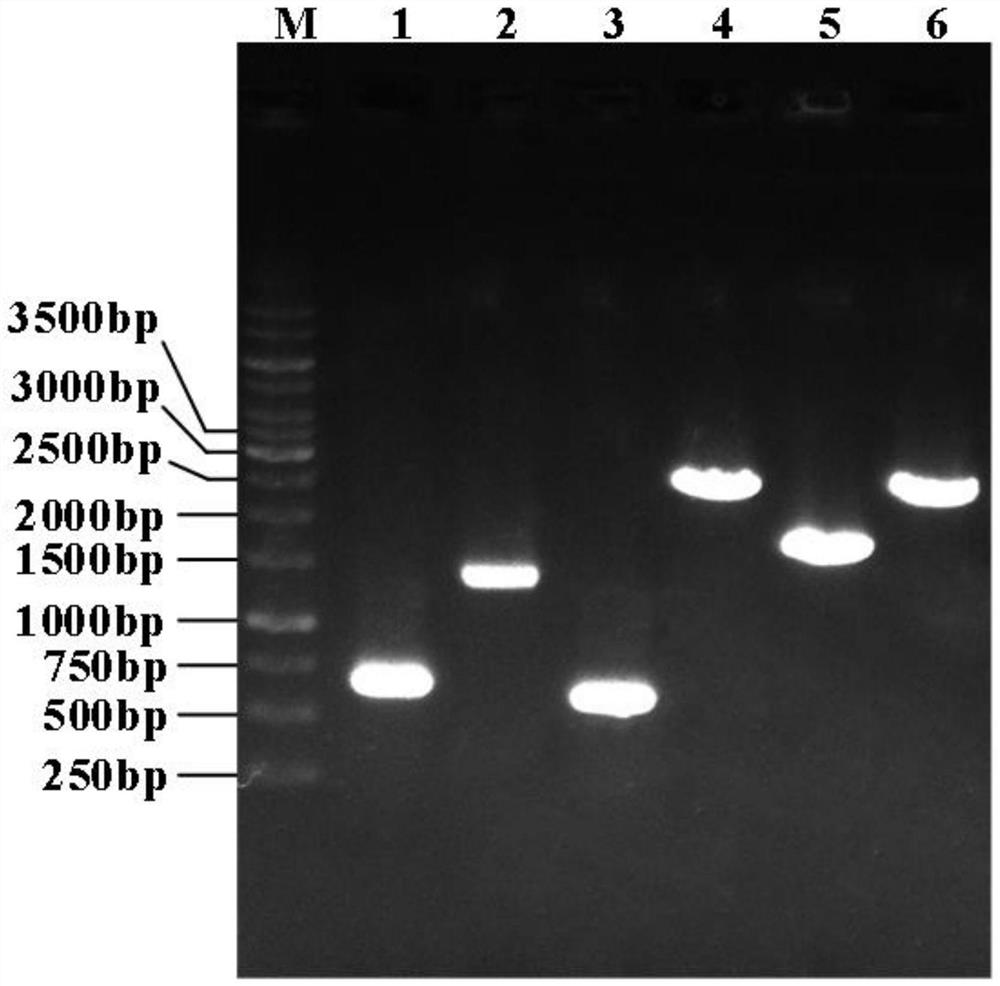

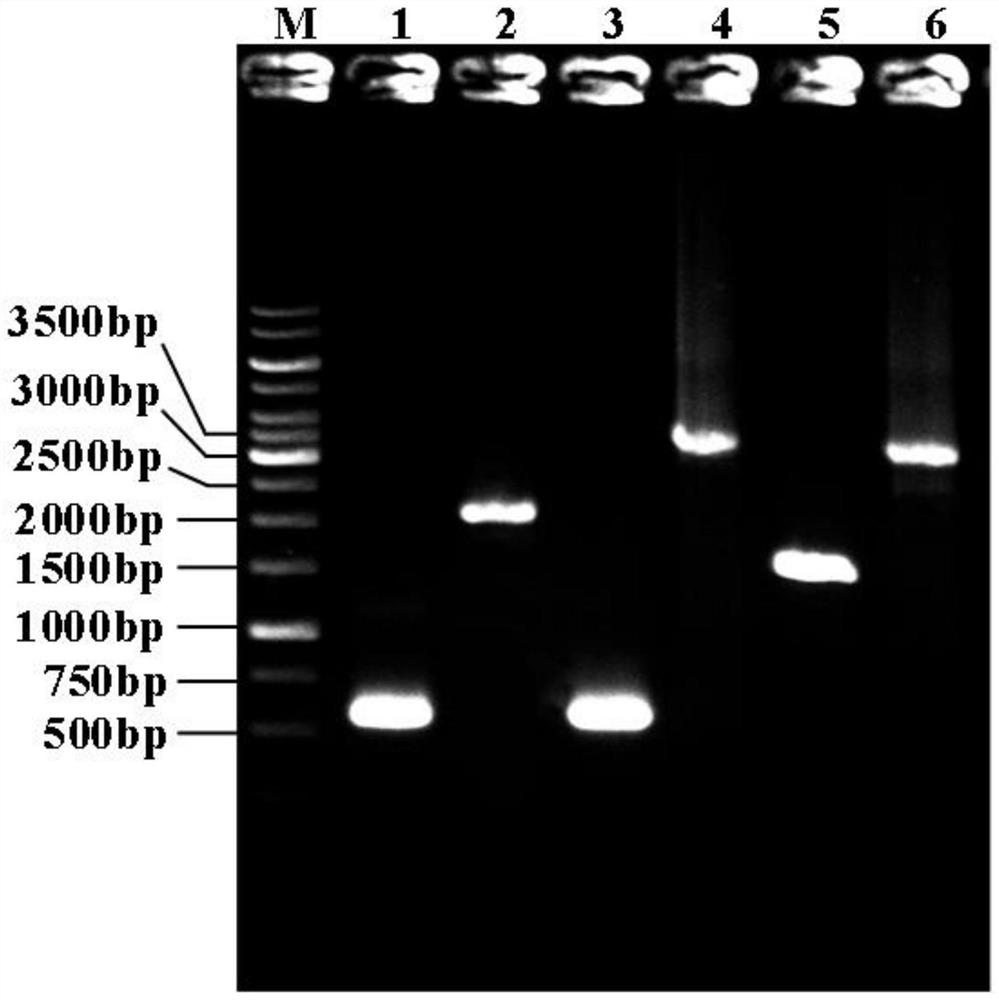

[0102] Example 1: Construction of gene engineering bacteria E.Coli E5

[0103] 1. The method of gene editing

[0104] In the present invention, the gene editing method mediated by CRISPR / CAS 9 refers to the literature (MetaboliceNGINEERING, 2015, 31: 13-21.). The two plasmids used in this method are PGRB and Predcas9, respectively. Among them, Predcas9 carries the GRNA plasmid elimination system, the red restructuring system of the λ phage and the CAS9 protein expression system, Qiithromycin resistance (work concentration: 100mg / L), 32 ℃ cultivation; PGRB plasmid, PUC18 as the skeleton, including promoter J23100000000 , GRNA-CAS9 combines regional sequences and terminate subeenters, ammonia gryimonicin resistance (working concentration: 100mg / L), 37 ℃ cultivation.

[0105] The specific steps of this method are as follows:

[0106] 1.1 PGRB plasmid construction

[0107] The purpose of constructing the plasmid PGRB is to transcribe the corresponding GRNA, so as to form a complex for...

Embodiment 2

[0162] Example 2: Use the genetic engineering bacteria E.Coli E5 fermentation to produce belline

[0163] (1) Shaking bottle fermentation:

[0164] The fermentation medium for fermentation of bottle fermentation becomes: glucose 10g / L, yeast powder 3g / L, protein 胨 4g / L, sodium citrate 1g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate 1g / L, iron sulfate iron 15mg / L, manganese sulfate 15mg / L, VB 1 , VB 3 , VB 5 , VB 12 V H Each 1mg / L, the rest is water, pH 7.0-7.2.

[0165] Fermentation process: Take -80 ° C to preserve the bacteria species and inoculate it in the active slope, cultivate 12 hours at 37 ° C, and spread it once. Use the inoculating ring to take a ring -to -ring seed in the 500ml triangle bottle equipped with a 30ml seed medium, seal the nine layers of gauze, 37 ° C, and 220rpm cultivation for 10h. The inoculation amount of 15 % of the seed culture liquid accumulation was inoculated to the 500ml triangular bottle (30ml of the final volume) equipped with a fe...

Embodiment 3

[0169] Example 3: Use the genetic engineering bacteria E.Coli E5 fermentation to produce belline

[0170] (1) Shaking bottle fermentation:

[0171] The fermentation medium for fermentation of bottle fermentation becomes: glucose 40g / L, yeast powder 4g / L, protein 胨 6g / L, sodium citrate 2g / L, potassium dihydrogen phosphate 6g / L, magnesium sulfate 2g / L, iron sulfate 20mg 20mg / L, manganese sulfate 20 mg / L, VB 1 , VB 3 , VB 5 , VB 12 V H 3mg / L each, the rest are water, pH 7.0-7.2.

[0172] Fermentation process: Take -80 ° C to preserve the bacteria species and inoculate it in the active slope, cultivate 12 hours at 37 ° C, and spread it once. Use the inoculating ring to take a ring -to -ring seed in the 500ml triangle bottle equipped with a 30ml seed medium, seal the nine layers of gauze, 37 ° C, and 220rpm cultivation for 10h. The inoculation amount of 20 % of the seed culture liquid accumulation is inoculated to a 500ml triangular bottle equipped with a fermented medium (the final v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com