Slow releasing micropill containing active component of indapamide and method for preparing the same

A technology of sustained-release pellets and indapamide, which is used in pharmaceutical formulations, bulk delivery, blood diseases, etc., can solve the problems of sudden release of sustained-release tablets and difficult quality control, and achieve increased safety, high yield and Reproducible, easy-to-industrial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

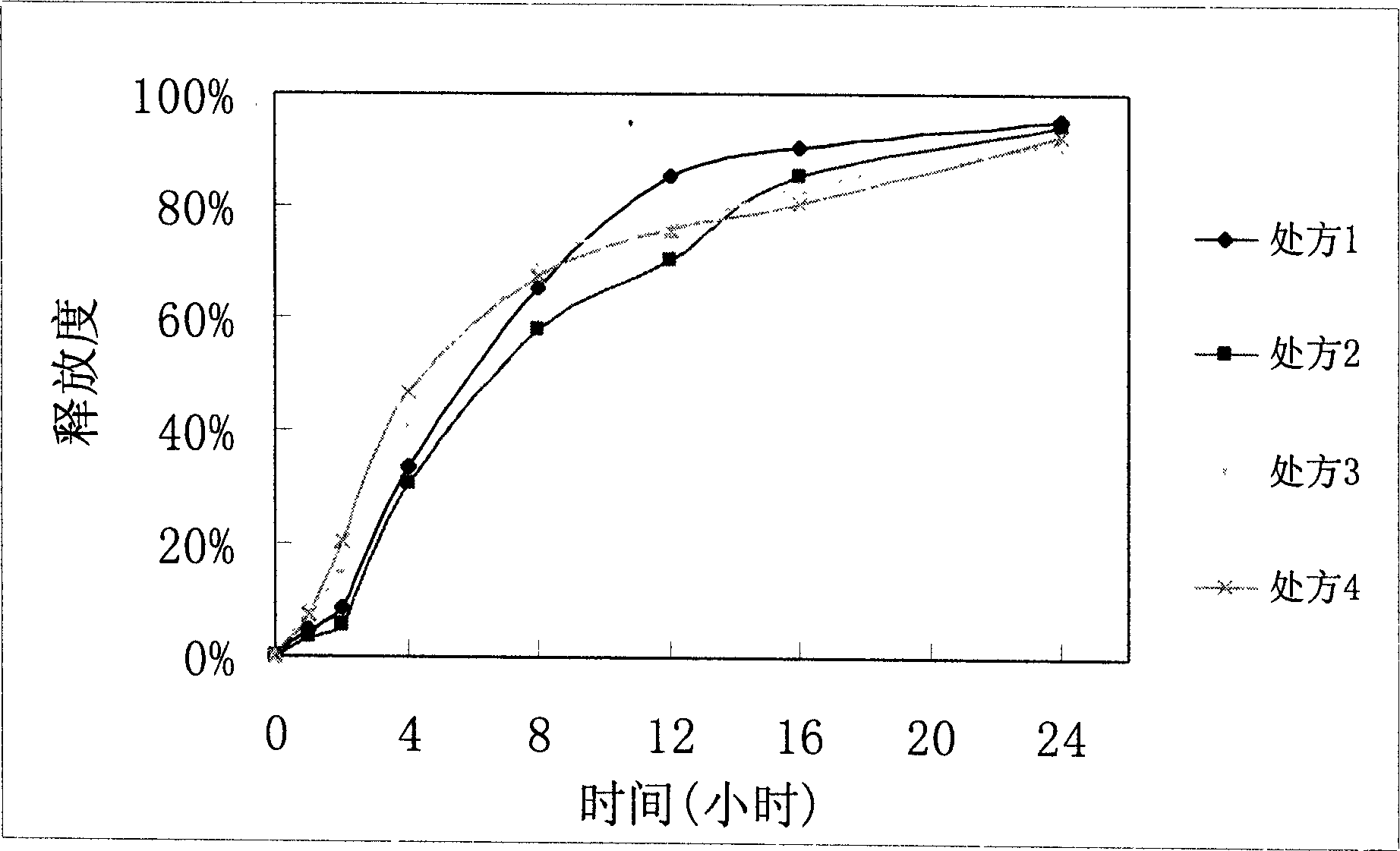

Image

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of blank pellet

[0040] 1

2

100g

30g

40g

20g

10g

silica

80g

60g

20g

20g

20g

[0041] B. Preparation process

[0042] Mix the prescription amount of lactose (or microcrystalline cellulose) and starch evenly, add the binder prepared by sucrose or hypromellose, use a granulator (or coating pan) to start and roll the pellets to the required The mesh number is 15-30 mesh (lubricant and glidant are added while rolling the pellets), dried, and the best 18-25 mesh is screened out.

Embodiment 2

[0043] Embodiment 2, the preparation of quick-release pellets

[0044] 1

2

Blank pellets

Indapamide

polyethylene glycol

water

120g

1.5g

2g

10g

0.4g

100ml

Blank pellets

Indapamide

polyethylene glycol

70% ethanol

120g

1.5g

5g

15g

0.3g

100ml

[0045] B. Preparation process

[0046] Add indapamide, hypromellose (or polyvinylpyrrolidone) and talcum powder described in the prescription into water or 70% ethanol respectively, and stir for 20 minutes to form a uniform mixed solution. In the fluidized bed (or coating pan), the temperature of the pellets was kept at 30° C., and the mixed solution was evenly sprayed on the outer layer of the blank pellets obtained in Example 1 to obtain immediate-release pellets.

Embodiment 3

[0047] Embodiment 3, the preparation of sustained-release pellets

[0048] 1

2

medicated pellets

Acrylic resin NE30D

Talc powder

water

150g

20g

3.5g

5g

150ml

medicated pellets

Acrylic RS30D

Acrylic resin RL30D

Talc powder

water

150g

15g

1.5g

3.8g

11.3g

135ml

3

4

medicated pellets

0.1% diethyl phthalate

75% ethanol

150g

10g

2g

5g

100ml

medicated pellets

Aqueous dispersion of ethyl cellulose

Talc powder

water

150g

15g

10g

100ml

[0049] B. Preparation process

[0050] Put the quick-release pellets obtained in Example 2 into a fluidized bed (or coating pan), and keep the temperature of the pellets at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com