Method of polymerization

A polymerization method and compound technology, applied in the field of polyolefin production, can solve the problems of low catalytic activity of hydroxyquinoline catalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

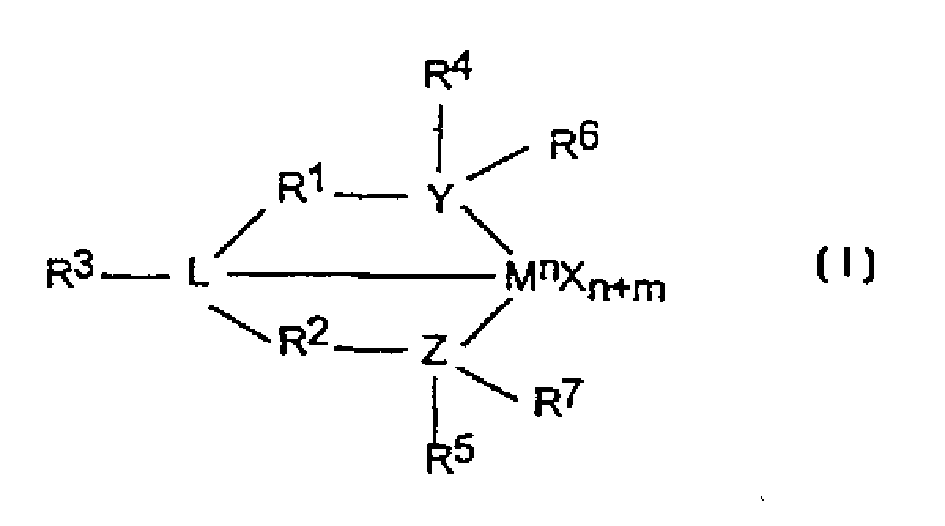

[0051] In a preferred embodiment, the present invention relates to a method for the preparation of a metal compound comprising: neutralizing a neutral complex at about 20°C or higher, preferably from about 20 to about 100°C, in a non-coordinating or weakly coordinating solvent Body and M n x n The indicated compound is reacted; then the mixture is treated with an excess of alkylating agent; then the metal complex is recovered; wherein M is the metal of Group 3-14, n is the oxidation state of M, and X is an anion leaving group. In a preferred embodiment, the solvent has a boiling point above 60°C, such as diethyl ether, toluene, xylene, benzene, methylene chloride and / or hexane.

[0052] In addition, the present invention also relates to a method for preparing a metal adduct, comprising: making a neutral ligand and m n x n Reaction of the compound represented; where M is Zr or Hf, n is the oxidation state of M, X is an anion leaving group, and then removes the metal adduct....

Embodiment 1

[0100] Embodiment 1: the preparation of catalyst A

[0101] [iPrNH(o-C 6 h 4 )] 2 Preparation of O

[0102] Add [H 2 N(o-C 6 h 4 )] 2 O (10.0 g, 50 mmol), acetone (15 mL), activated Zn powder (25.0 g, 382 mmol) and glacial acetic acid (100 mL). The flask was capped with a rubber septum, connected by a needle to an oil bubbler, and then heated to 60° C. for 24 hours with rapid stirring. After cooling to room temperature, the reaction mixture was poured into ice (200 mL), concentrated aqueous ammonia (200 mL), and dichloromethane (150 mL). The layers were separated and the aqueous layer was extracted with dichloromethane (2 x 100 mL). The combined dichloromethane layers were extracted over magnesium sulfate. After removal of the dichloromethane under vacuum, the crude product was obtained as an orange oil. The resulting oil was dissolved in acetone (150 mL) and concentrated hydrochloric acid (10 mL) was added. Colorless crystals will begin to form within one minute. ...

Embodiment 2

[0112] Example 2: Slurry Phase Ethylene-Hexene Polymerization

[0113] Slurry phase polymerizations were carried out in a 1-liter high-pressure reactor equipped with a mechanical stirrer, external water jacket for temperature control, bulkhead inlet and vent lines, and regulation of anhydrous nitrogen and ethylene source of supply. The reactor was dried and degassed at 160°C. Isobutane (400 mL) was added as diluent and, using a gas-tight syringe, 35 mL of 1-hexene was added as scavenger, and 0.4 mL of a 25% by weight solution of triisobutylaluminum in hexane. The reactor was heated to 60°C. 0.256 g of finished Catalyst A was added using ethylene pressure and the reactor was pressurized with 79 psi (545 kPa) of ethylene. The polymerization was continued for 30 minutes while maintaining the temperature and pressure of the reactor at 60°C and 79 psi (545 kPa) by a constant flow of ethylene. The reaction was quenched by rapid cooling and evacuation. No polymer was recovered. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com