Preparation process of zinc oxide bar shape single crystal nano-probe

A single crystal nano, zinc oxide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of limited specific surface area, expensive and complicated equipment, unfavorable low-cost mass production and processing, etc. The effect of large surface area and improved specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

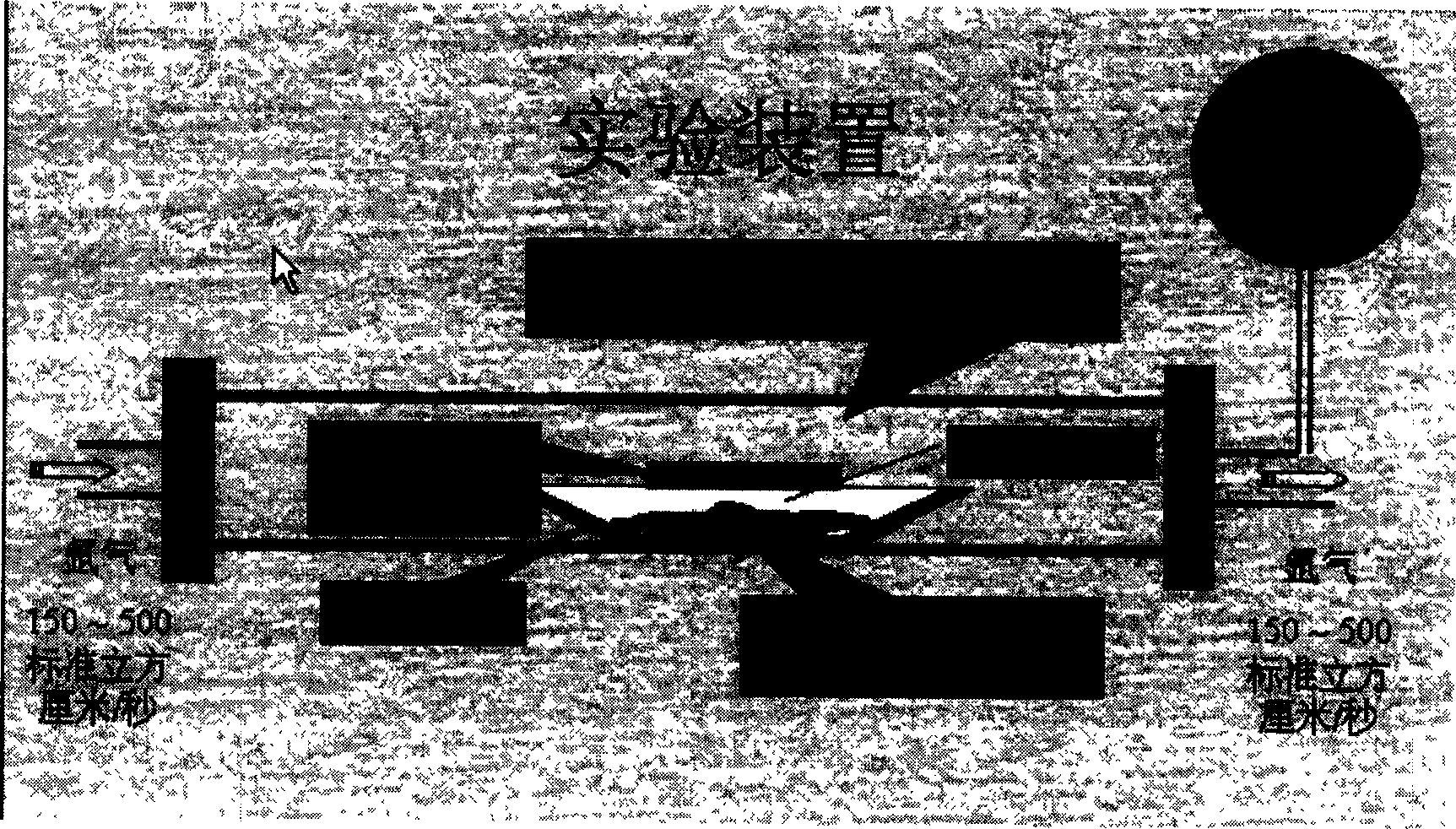

[0016] The preparation method of the nanoprobe in the present invention is mainly based on the gas-liquid-solid synthesis of semiconductor quasi-one-dimensional nanostructures. The method is to use clean (0001) or (1120) direction sapphire (Sapphire, also known as white gem, the molecular formula is Al 2 o 3 ) polished epitaxial substrate or a silicon single crystal substrate in (111) direction as a substrate; the subsequent preparation process is:

[0017] Depositing a metal (such as gold or nickel) particle film with a nominal thickness of 1 to 10 nanometers on the above substrate by using sputtering equipment;

[0018] Keep the side coated with the particle film facing down, and fix the substrate horizontally on a small porcelain boat filled with metal zinc powder (chemically pure or higher), and keep the distance between the substrate and the zinc powder at 2 to 10 mm;

[0019] Place the ceramic boat prepared in the above steps in the center of the heating tube of the ho...

Embodiment 1

[0022] 1. Prepare a 10×5×0.5 cubic millimeter sapphire single crystal polished epitaxial substrate with (0001) crystal orientation, clean it ultrasonically with acetone for 1 hour, and deposit a layer of nominal thickness on the substrate by sputtering equipment after drying. 2nm gold film, the substrate temperature during sputtering is room temperature, and the vacuum degree is not higher than 2×10 -2 Torr;

[0023] 2. Wash the heating tube (corundum tube) of the horizontal tubular heating electric furnace with distilled water, and then rinse twice with acetone; ultrasonically clean the 9 cm long porcelain boat with acetone for half an hour; weigh 5 grams of zinc powder (100 mesh , 99.9%, Alpha Alfa Aesar), tiled into the cleaned porcelain boat;

[0024] 3. Place the prepared sapphire substrate coated with gold film horizontally on the porcelain boat filled with zinc powder in step 2, keep the side coated with gold film vertically downward, facing the zinc powder reaction so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com