Chloramphenicol affinity column and preparation method and use thereof

A chloramphenicol and affinity column technology, applied in the field of chloramphenicol affinity column, can solve the problems of elution residue, limited number of reusable times and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

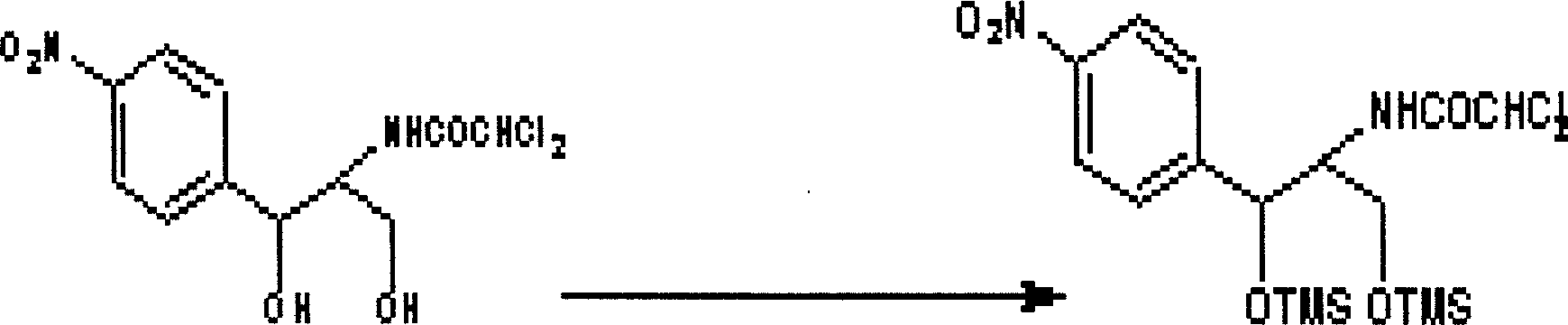

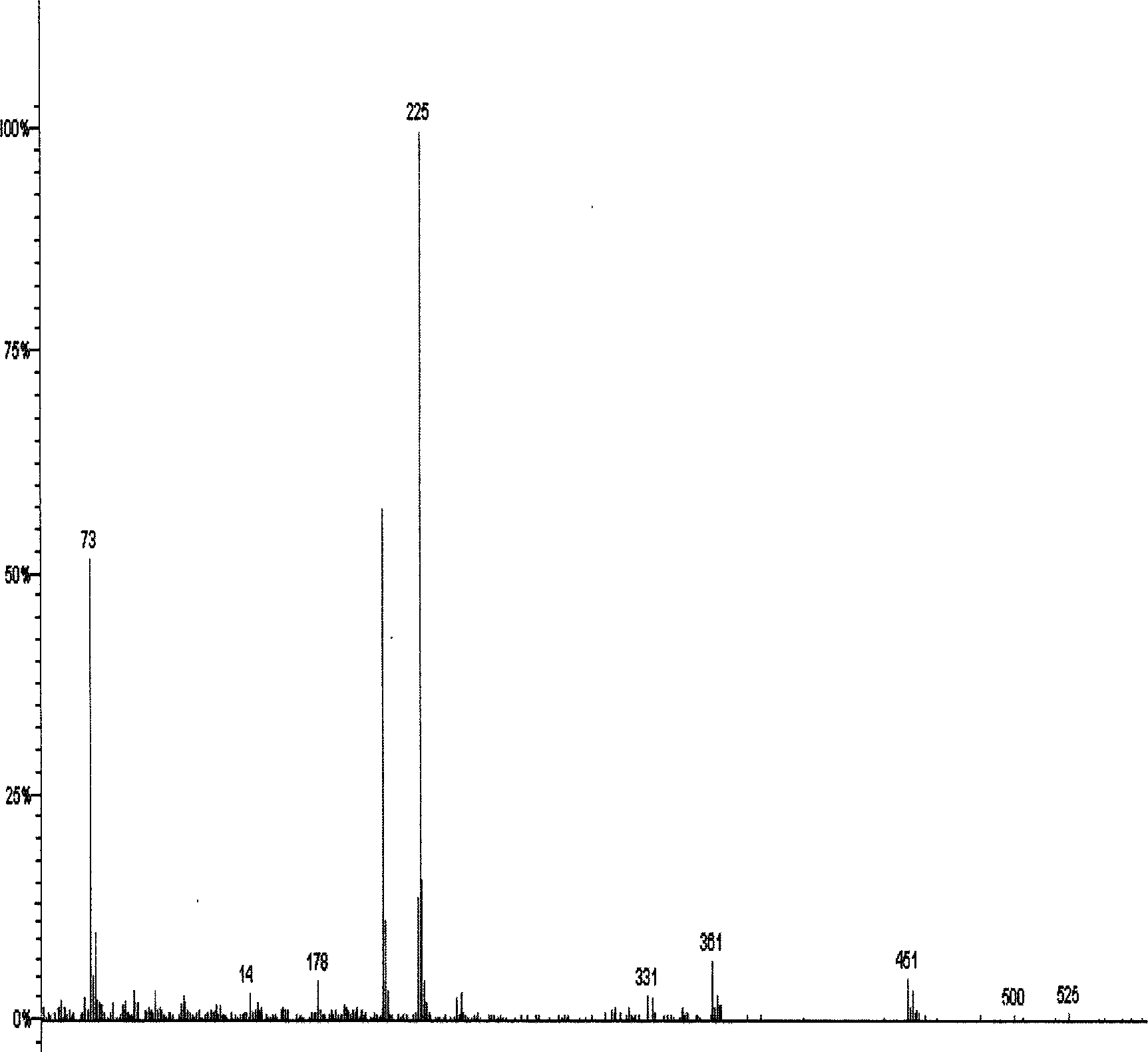

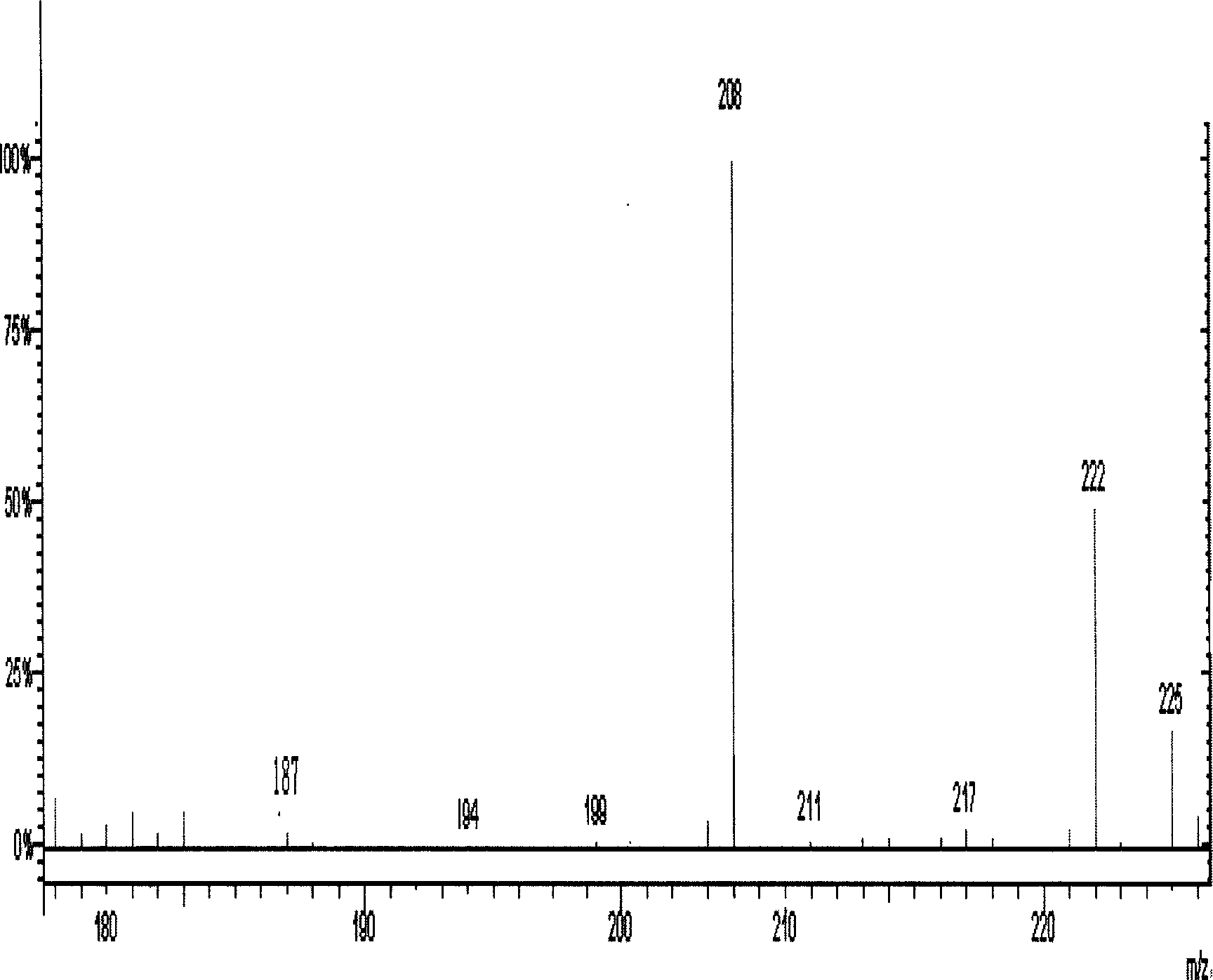

Image

Examples

Embodiment 1

[0058] This example is the preparation of chloramphenicol immunoaffinity column.

[0059] Reagents used

[0060] Chloramphenicol polyclonal antibody: BSA-succinic chloramphenicol immunized rabbits, and the immune serum was purified by ammonium sulfate precipitation (protein concentration 5 mg / ml); Protein A Sepharose (PharmaciaBiotech); Dimethylpimelate ( Pierce Bitochnology, DMP); methanol, ethanolamine, triethanolamine, thimerosal sodium, NaCL, KCL, KH 2 PO 4 、Na 2 HPO 4 12H 2 O.

[0061] Buffer configuration

[0062] 0.3M potassium phosphate buffer, pH 8.0: 64.8g K 2 HPO 4 ·3H 2 O, dissolved in distilled water to 1000ml, adjusted to pH 8.2 with phosphoric acid; 0.01mol / L phosphate buffer (PBS, pH 7.4): NaCL 8.00g, KCL 0.2g, KH 2 PO 4 0.2g, Na 2 HPO 4 12H 2 O 2.90g, dissolved in distilled water to 1000ml; phosphate buffered saline (PBS-0.01%) containing 0.01% thimerosal sodium; 0.2mol / L triethanolamine solution (pH8.2): 5.968g of triethanolamine dissolved in di...

Embodiment 2

[0073] The chloramphenicol immunoaffinity column was prepared by the method described in Example 1, and the affinity column was reused to measure the recovery of the spiked honey samples with complex matrices in food. The spiked levels were 0.1, 0.3, and 1.0 μg / Kg, respectively.

[0074] Extraction: Weigh 5g of honey sample, add 10ml of ultrapure water, shake to dissolve; add 25ml of ethyl acetate, shake and extract for 30 minutes, centrifuge at 3500rpm for 5 minutes, transfer the upper organic phase with a dropper, repeat the ethyl acetate extraction process to combine the organic phase; add 5ml of 0.3M potassium phosphate buffer solution was rotatably evaporated at 45°C until water mist appeared at the mouth of the bottle; the evaporation residue was dissolved in 10ml of 0.3M potassium phosphate buffer solution and passed through an affinity column.

[0075] Purification: take the prepared chloramphenicol immunoaffinity column out of the refrigerator at 4°C, and place it at r...

Embodiment 3

[0081] The chloramphenicol immunoaffinity column was prepared by the method described in Example 1, and the spiked recovery of the shrimp sample was measured, and the spiked levels were 0.1, 0.3, and 1.0 μg / Kg, respectively.

[0082] Extraction: Weigh 5g of blank shrimp sample, add chloramphenicol standard, add 10ml ultrapure water, shake to dissolve; add 25ml ethyl acetate shake and extract for 30 minutes, centrifuge at 3500rpm for 5 minutes, transfer the upper organic phase with a dropper, repeat ethyl acetate Combine the organic phase during the extraction process; add 5ml of 0.3M potassium phosphate buffer solution, and evaporate under reduced pressure at 45°C until water mist appears at the bottle mouth; dissolve the evaporation residue in 10ml of 0.3M potassium phosphate buffer solution, and then use 2ml of n-hexane solution respectively Liquid extraction 2 times to remove fat and set aside.

[0083] Purification: take the prepared chloramphenicol immunoaffinity column o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com