Supported TiO2 photocatalyst, its preparation method and photocatalytic water purifier

A photocatalyst and load-type technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, light water/sewage treatment, etc., can solve the problems of low photocatalytic efficiency, achieve easy-to-obtain raw materials, loose preparation process conditions, High adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

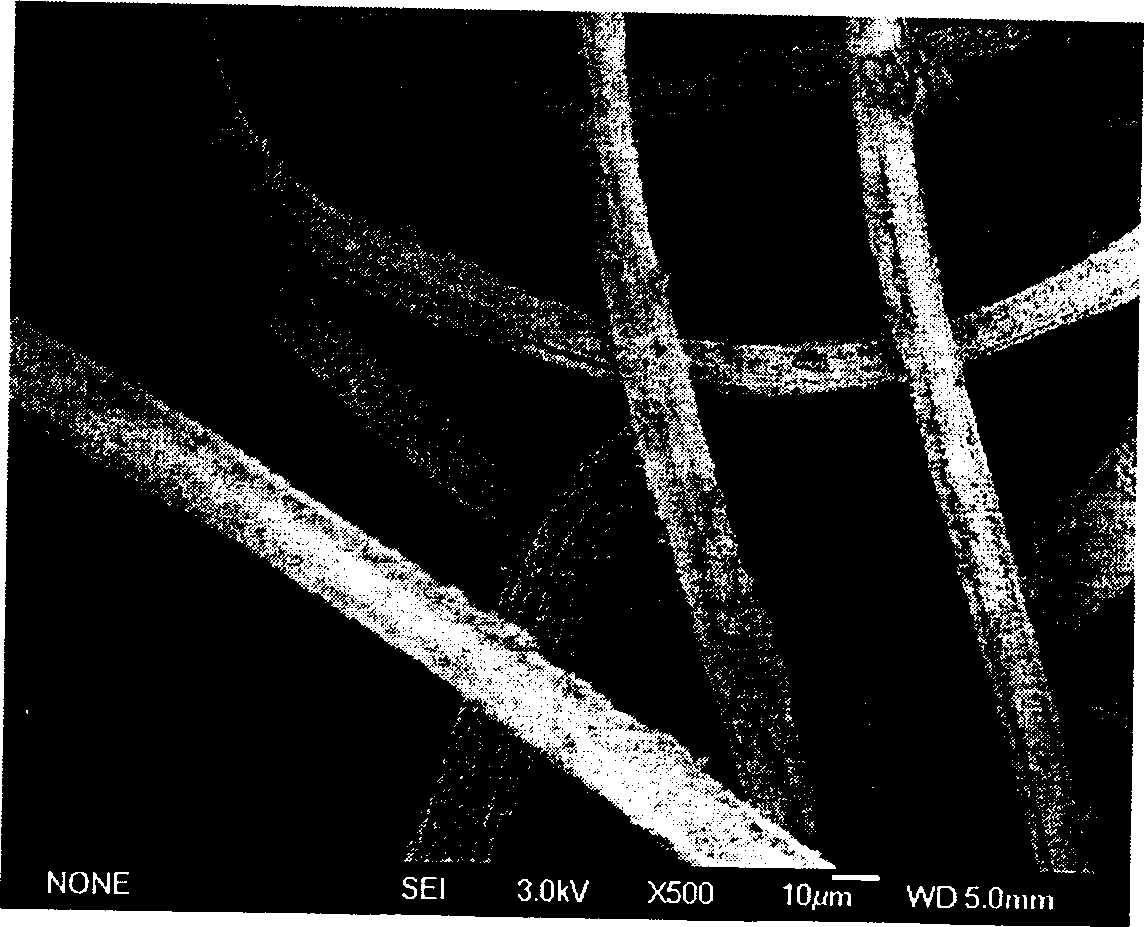

[0026] Embodiment 1, use the powder coating method of viscose to prepare supported TiO 2 Photocatalyst TiO 2 / ACFs-A

[0027] Commercially available P25TiO 2 Powder (particle size less than 50nm, crystal form is anatase phase) mixed with deionized water, combined with mechanical stirring and ultrasonic dispersion to prepare TiO 2 TiO with a solid content of 4wt% 2 Suspension, then add water-soluble organosilicon modified acrylic emulsion (silicon acrylic suspension) (in milky white, solid content is 40wt%, polymerization degree is 3000) as viscose agent, its addition is TiO 2 0.5wt% of the amount, and then ultrasonically dispersed to form highly dispersed TiO with a certain viscosity 2 suspension.

[0028] Activated carbon fibers impregnated with prepared TiO after surface cleaning 2 In the suspension, after being pulled out, the excess suspension in the fiber filaments is shaken off. After the suspension is dried by cold air, it is then immersed in TiO 2 Suspension, th...

Embodiment 2

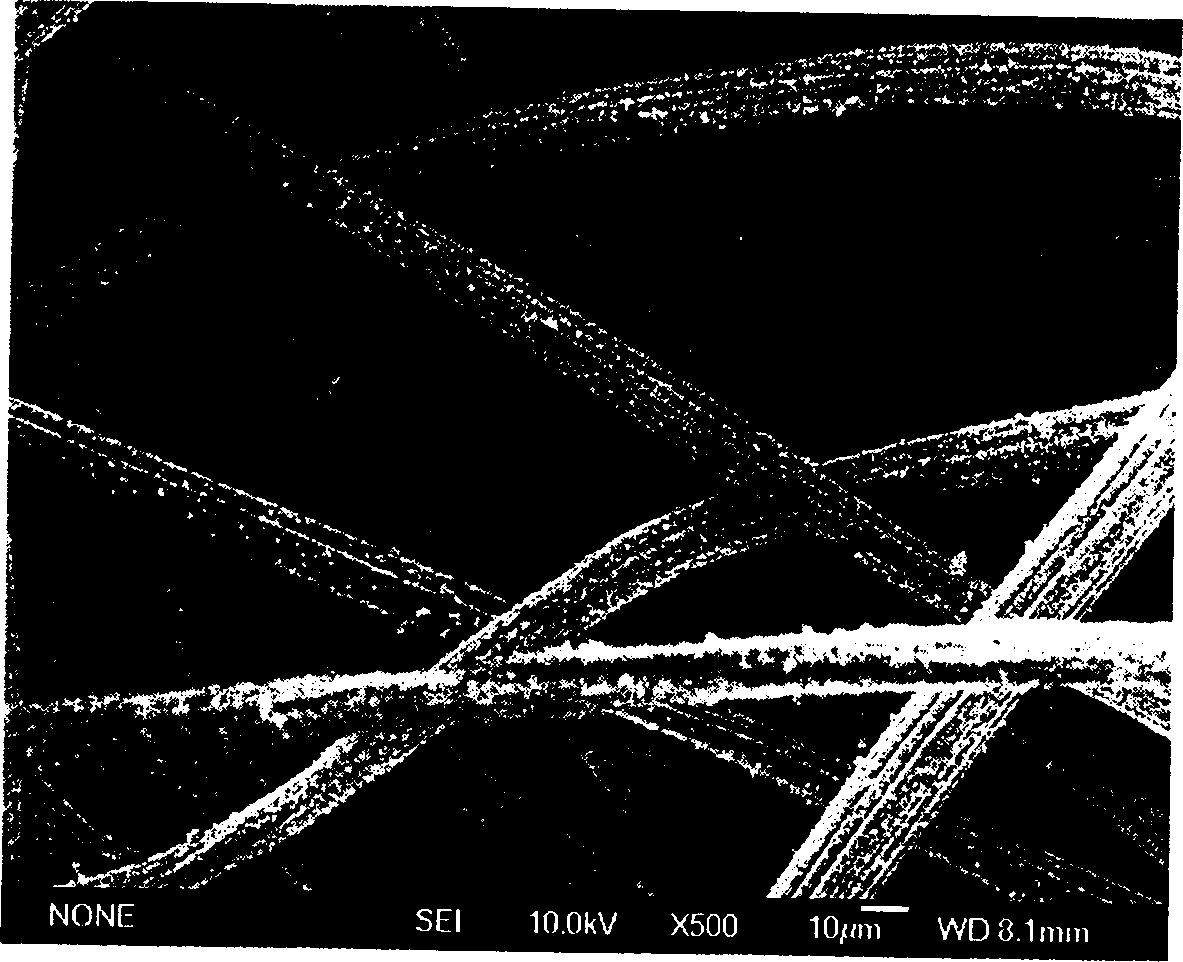

[0030] Embodiment 2, use liquid phase deposition method to prepare supported TiO 2 Photocatalyst TiO 2 / ACFs-B

[0031] Use deionized water to prepare ammonium fluorotitanate solution with a concentration of 0.07 mol / L and a boric acid solution with a concentration of 0.5 mol / L, and then mix them to form a mixed solution with a molar ratio of ammonium fluorotitanate and boric acid of 1:3. Hydrochloric acid adjusted the pH of the mixture to 3.0.

[0032] Insert the cleaned activated carbon fiber into the above mixed solution, keep the temperature of the mixed solution at 50°C, and after liquid phase deposition for 20 hours, take out the activated carbon fiber and dry it, then bake it at 600°C for 1 hour under the protection of nitrogen, and get Obtain the loaded TiO of the present invention 2 Photocatalyst TiO 2 / ACFs-B. The supported TiO 2 Photocatalyst TiO 2 / ACFs-B is based on activated carbon fiber matrix, loaded with TiO 2 The loading amount is 324mg TiO 2 / g acti...

Embodiment 3

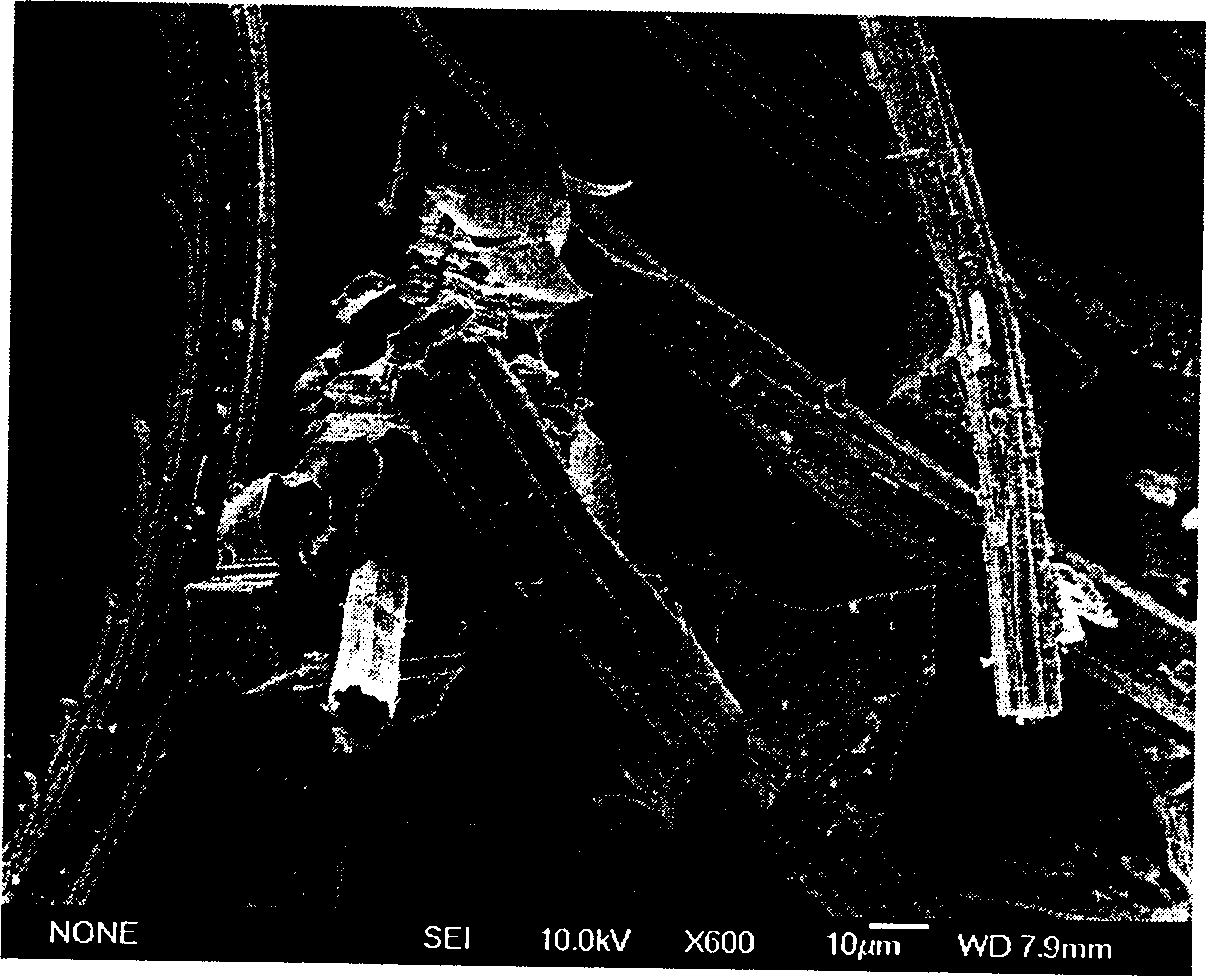

[0033] Embodiment 3, use sol-gel method to prepare loaded TiO 2 Photocatalyst TiO 2 / ACFs-C

[0034] Prepare a precursor solution with tetra-n-butyl titanate as a precursor, wherein the volume ratio of each component is: tetra-n-butyl titanate: absolute ethanol: distilled water: glacial acetic acid = 1:8:2:10, and the order of addition is : First, mix tetra-n-butyl titanate and absolute ethanol in a given volume ratio, stir evenly to form solution A; mix distilled water and glacial acetic acid in a given volume ratio to form solution B, and then mix solution A with 2ml / The speed of min is added dropwise into the stirring solution B to prepare a precursor solution.

[0035] Immerse the cleaned activated carbon fiber in the above precursor solution, and let it stand in a ventilated place for 2 days to gel to obtain a transparent sol with a certain viscosity, pull the immersed activated carbon fiber, dry the glue, and then immerse in the above sol Pull it out again, after 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com