Method for preparing TiO2 photocatalytic film doped with non-metallic element

A technology of photocatalytic thin films and non-metallic elements, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of single doping elements and difficult control of doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

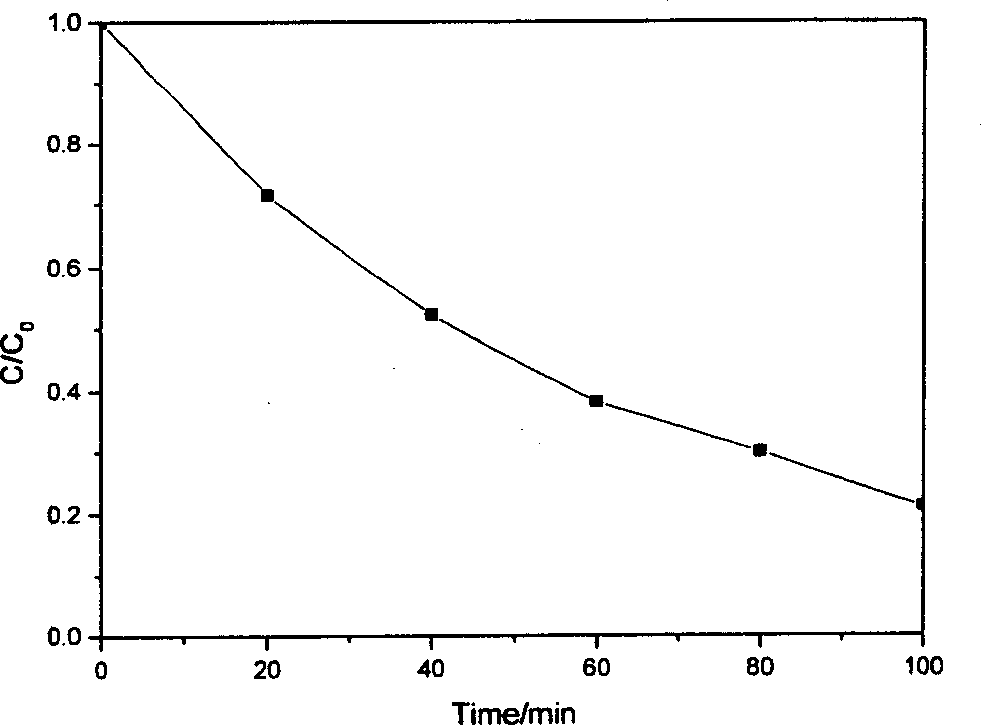

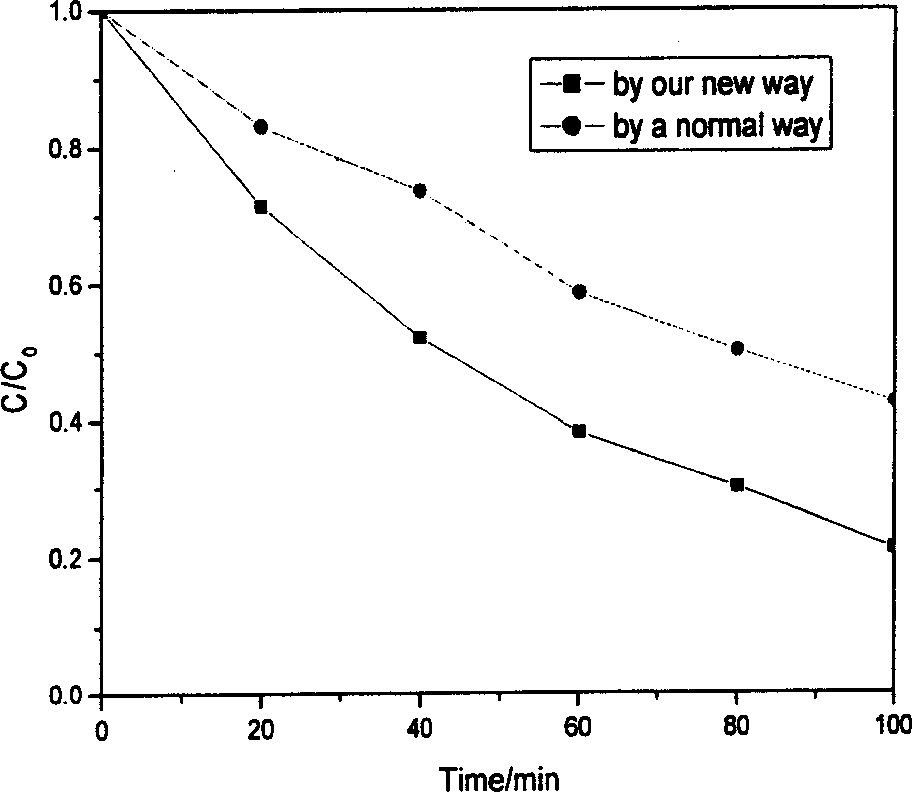

Image

Examples

Embodiment 1

[0021] Add 20mL of titanium tetrachloride dropwise to 200mL of 6M hydrochloric acid, and stir at a constant temperature of 40°C to obtain TiO 2 Sol, aged at 80°C for 4 hours;

[0022] Add hydrochloric acid to polydipropylene dimethyl ammonium chloride to prepare a cationic solution, wherein the concentration of polydipropylene dimethyl ammonium chloride is 0.005 mol / L, and the concentration of hydrogen ions is 0.1 mol / L;

[0023] Add hydrochloric acid to sodium polystyrene sulfonate (PSS) to configure an anion solution, wherein the concentration of sodium polystyrene sulfonate is 0.005 mol / L, and the concentration of hydrogen ions is 0.1 mol / L;

[0024] Sonicate the quartz glass in a mixture of 20mL 98% concentrated sulfuric acid and 10mL 30% hydrogen peroxide at 80°C for 10 minutes, then in deionized water for 10 minutes, and dry in the air;

[0025] Immerse the treated quartz glass support body in the polydipropylene dimethyl ammonium chloride solution for 10 minutes, so th...

Embodiment 2

[0031] Mix butyl titanate, absolute ethanol, deionized water and acid catalyst in a molar ratio of 1:100:10:0.5, stir and heat at 80°C for 4 hours to obtain positively charged TiO 2 Sol, aged at 80°C for 4 hours;

[0032] Add hydrochloric acid to polyvinyl alcohol and polydipropylene dimethyl ammonium chloride to form a polycation aqueous solution. The concentration of polyvinyl alcohol and polydipropylene dimethyl ammonium chloride is 0.01M, and the hydrogen ion concentration is 0.0001M ;

[0033] Add hydrochloric acid to sodium polystyrene sulfonate (PSS) and sodium polyacrylate (PAAS) to form a polyanion aqueous solution. The concentrations of sodium polystyrene sulfonate (PSS) and sodium polyacrylate (PAAS) are both 0.01M. The hydrogen ion concentration is 0.0001M;

[0034] After the ceramic microfiltration membrane matrix is dried, it is fired at 500-550°C for 2-5 hours, and the obtained SiO 2 -Al 2 o 3 Inorganic composite membrane matrix was washed twice with acet...

Embodiment 3

[0042] Add 20mL of titanium tetrachloride dropwise to 200mL of 6M hydrochloric acid, and stir at a constant temperature of 40°C to obtain TiO 2 Sol, aged at 80°C for 4 hours;

[0043] Add hydrochloric acid to polydipropylene dimethyl ammonium chloride to prepare a cationic solution, wherein the concentration of polydipropylene dimethyl ammonium chloride is 0.05 mol / L, and the concentration of hydrogen ions is 0.0001 mol / L;

[0044] Add hydrochloric acid to polystyrene sodium sulfonate (PSS) to configure an anion solution, wherein the concentration of sodium polystyrene sulfonate is 0.05mol / L, and the concentration of hydrogen ions is 0.0001mol / L;

[0045] Sonicate the ITO glass in 30mL of 98% concentrated sulfuric acid and 10mL of 30% hydrogen peroxide mixture at 80°C for 30 minutes, then in deionized water for 30 minutes, and dry in the air;

[0046] Immerse the treated ITO glass support body in the polydipropylene dimethyl ammonium chloride solution for 20min, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com