Preparation method of high quality magnetic material Mn3O4 ultrafine powder

A magnetic material and ultrafine powder technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of difficult control of particle size and particle size distribution, complex process and equipment, high reaction temperature and energy consumption, and achieve easy large-scale industry The effect of chemical production, excellent magnetic and catalytic properties, reaction temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 1.58g KMnO 4 The powder is dissolved in 0.15mol / L NaOH aqueous solution, then add 1.5mL cyclohexanone (keep the volume sum of NaOH aqueous solution and cyclohexanone 40mL), stir; then put it into a 50mL airtight autoclave, Hydrothermal reaction was carried out at 150°C and autogenous pressure for 24 hours; after it was naturally cooled to room temperature, the solid product was filtered with suction and washed with distilled water; dried to obtain the product Mn 3 o 4 Ultrafine powder.

[0021] Explanation of test results:

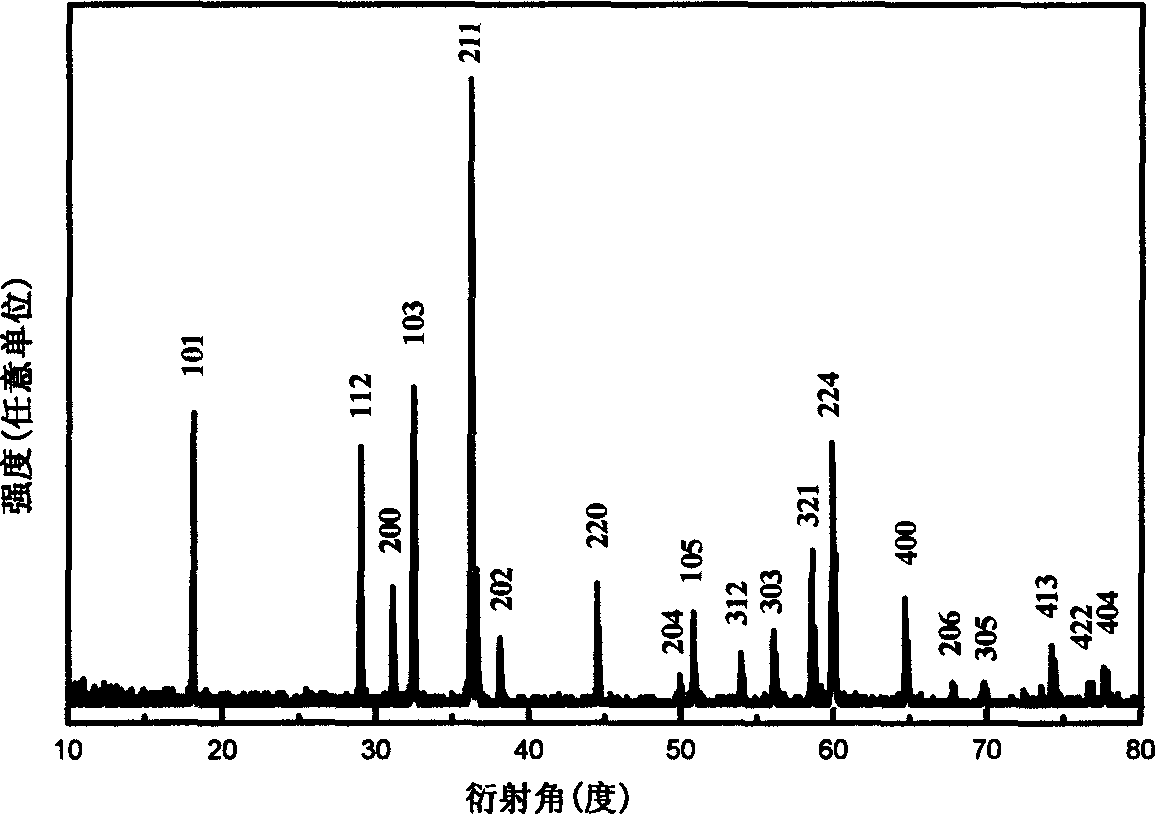

[0022] Such as figure 1 Shown: the X-ray diffraction pattern of the product produced in Example 1 of the present invention (using Bruker D8 Advance X-ray powder diffractometer (Cu Kα radiation, λ=1.5406 Å) to determine the crystal structure of the prepared material). All its X-ray diffraction peaks from left to right correspond to the tetragonal Mn 3 o 4 (101), (112), (200), (103), (211), (202), (220), (204), (105), (312), (303), (321), (...

Embodiment 2

[0025] Take 1.58g KMnO 4 Dissolve the powder in 1.0mol / L NaOH aqueous solution, then add 1.5mL cyclohexanone (keep the volume sum of NaOH aqueous solution and cyclohexanone 40mL), stir; then put it into a 50mL airtight autoclave, Hydrothermal reaction was carried out at 150°C and autogenous pressure for 24 hours; after it was naturally cooled to room temperature, the solid product was filtered with suction and washed with distilled water; dried to obtain the product Mn 3 o 4 Ultrafine powder.

[0026] Explanation of test results:

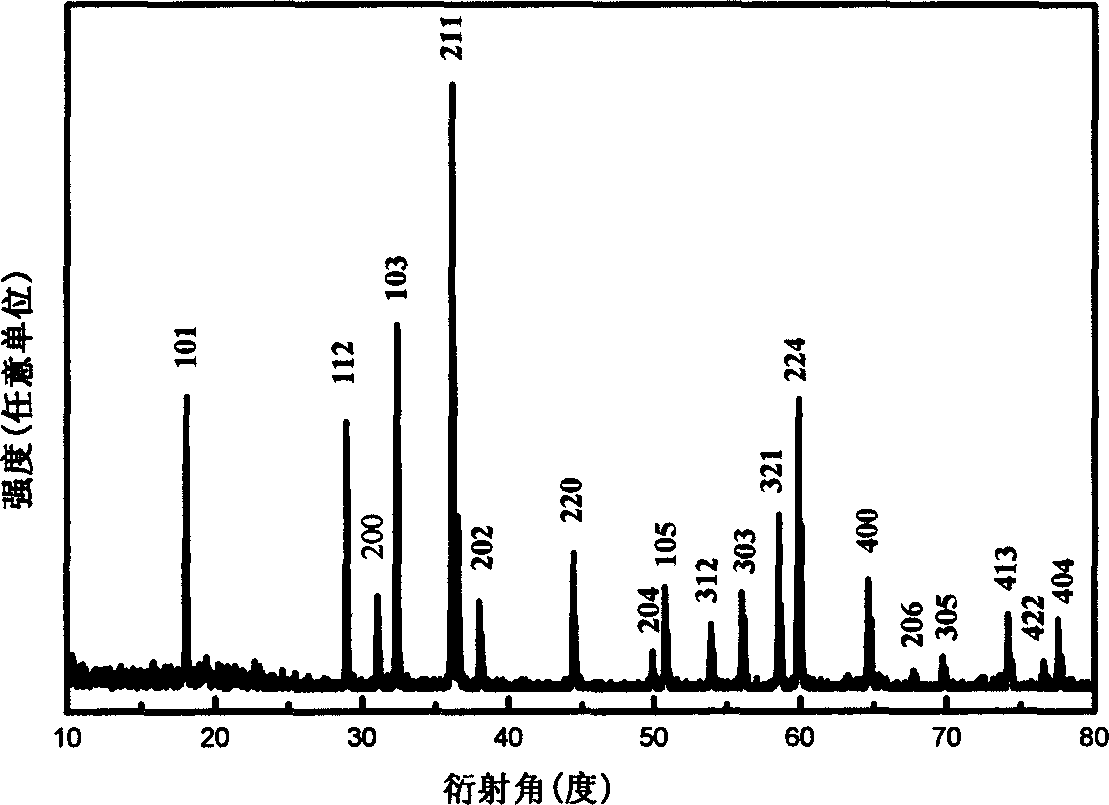

[0027] Such as image 3 Shown: the X-ray diffractogram of the product made in embodiment 2 of the present invention (instrument is the same as embodiment 1). All its X-ray diffraction peaks from left to right correspond to the tetragonal Mn 3 o 4 (101), (112), (200), (103), (211), (202), (220), (204), (105), (312), (303), (321), ( 224), (400), (206), (305), (413), (412), (404) crystal faces, illustrating that the product produced in Example 2...

Embodiment 3

[0030] Take 1.58g KMnO 4 Dissolve the powder in 0.30mol / L NaOH aqueous solution, then add 1.5mL cyclohexanone (to keep the volume of NaOH aqueous solution and cyclohexanone as 40mL), stir; ℃ and its own pressure for 10 hours of hydrothermal reaction; after it was naturally cooled to room temperature, the solid product was filtered with suction and washed with distilled water; dried to obtain the required Mn 3 o 4 Ultrafine powder.

[0031] Explanation of test results:

[0032] Such as Figure 5 Shown: the X-ray diffraction figure of the product of the embodiment of the present invention 3 (instrument is the same as embodiment 1). All its X-ray diffraction peaks from left to right correspond to the tetragonal Mn 3 o 4 (101), (112), (200), (103), (211), (202), (220), (204), (105), (312), (303), (321), ( 224), (400), (206), (305), (413), (412), (404) crystal faces, illustrating that the product prepared in Example 3 is pure tetragonal phase Mn with good crystallinity 3 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com