Nanometer carbonic anhydrase grain for biological catalysis of polymer and its prepn process

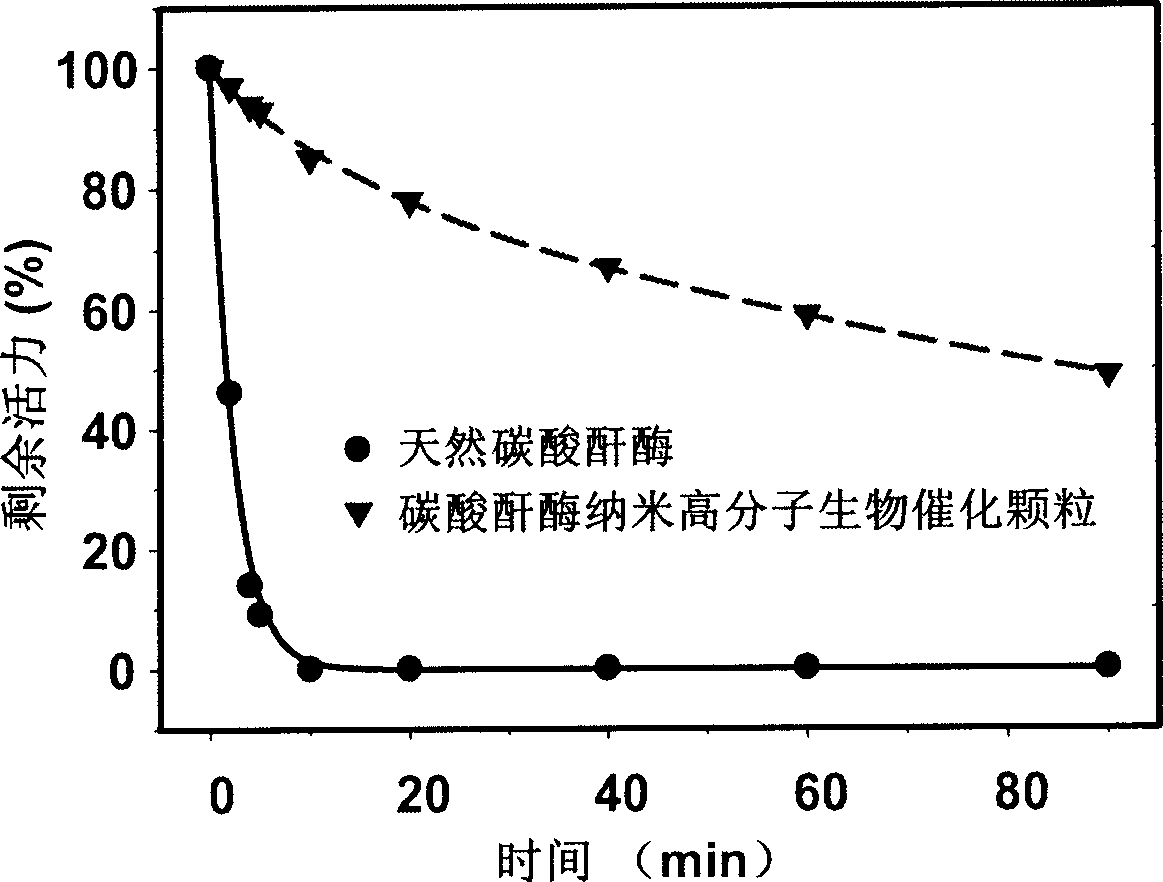

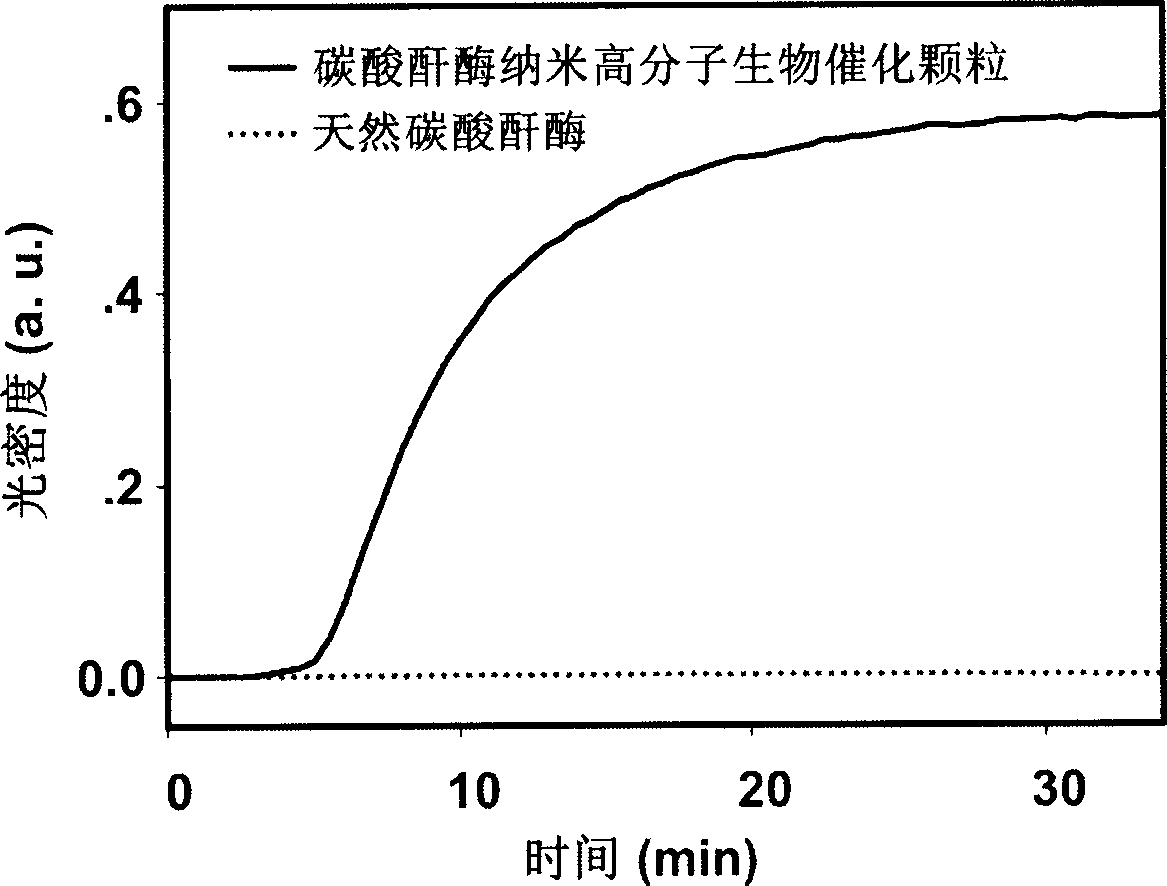

A nano-polymer, carbonic anhydrase technology, applied in the direction of enzyme stabilization, can solve the problems of insignificant improvement of chemical modification stability effect, high mass transfer resistance of immobilized carbonic anhydrase, poor thermal stability, etc., and achieves inhibition of direct hydrophobicity. Interactions and electrostatic interactions, enhancing rigidity, preventing deactivation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Example 1: The raw material is 10 parts by weight of bovine carbonic anhydrase, the enzyme modifier is 2 parts by weight of succinimide acrylate, and the alkenyl monomer is 18 parts of acrylamide and 4.5 parts of methylenebis Acrylamide, a total of 22.5 parts, the initiator is 2 parts of ammonium persulfate and 3 parts of N, N, N', N'-tetramethylethylenediamine, a total of 5 parts. The above-mentioned bovine carbonic anhydrase and enzyme modifier were added into 20 mM boric acid buffer solution with a pH of 8.5, reacted at 4° C. for 2 hours, and dialyzed with water to remove the modifier and borate. Add the obtained mixture to 1% aqueous solution of dimethyl sulfoxide, add 50% of the amount of alkenyl monomer, keep the temperature at 10°C, stir magnetically, add the initiator, react for 0.5 hours, add the remaining alkenyl monomer Keep the temperature at 10°C, continue to react for 2 hours, then use deionized water to dialyze for 12 hours, freeze-dry to obtain bovine car...

Embodiment 2

[0037] Embodiment 2: The raw material is 10 parts by weight of bovine carbonic anhydrase, the enzyme modifier is 5 parts by weight of acryloyl chloride, and the alkenyl monomer is 60 parts of acrylamide and 15 parts of methylenebisacrylamide. 75 parts, the initiator is 5 parts of ammonium persulfate and 10 parts of N, N, N', N'-tetramethylethylenediamine, a total of 15 parts. The above-mentioned bovine carbonic anhydrase and enzyme modifier were added to 200 mM sodium phosphate buffer solution with a pH of 7.5, reacted at 4° C. for 2 hours, and dialyzed with water to remove the modifier and phosphate. The resulting mixture was added to 1% acetonitrile aqueous solution, 20% of the amount of vinyl monomer was added, the temperature was maintained at 10 °C, magnetic stirring was added, the initiator was added, and the reaction was carried out for 0.5 hours, the remaining vinyl monomer was added, and the temperature was maintained The temperature is 10°C, and the reaction is conti...

Embodiment 3

[0038] Embodiment 3: Change the enzyme modifier in embodiment 2 to 10 parts of itaconic anhydride, the vinyl monomer is 80 parts of acrylamide and 20 parts of trihydroxymethylpropane trimethacrylate, free radical reaction solution 4% dioxane, the reaction temperature is 25°C, the initiator is 10 parts of potassium persulfate and 5 parts of sodium bisulfite, all the other formulas and steps are the same as in Example 2, and the stability of the product is obtained now , Activity yield and polymerization yield are equivalent to Example 2, and the product particle diameter is 45~55nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com