Polyformamine treatment thermal stabilizing method

A technology of thermal stabilization and formaldehyde amine, applied in the field of thermal stabilization of polyoxymethylene amine treatment, can solve the problems of increasing the amount of formaldehyde, increasing the process of cleaning, purifying and drying POM, and the surface deterioration of molded products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

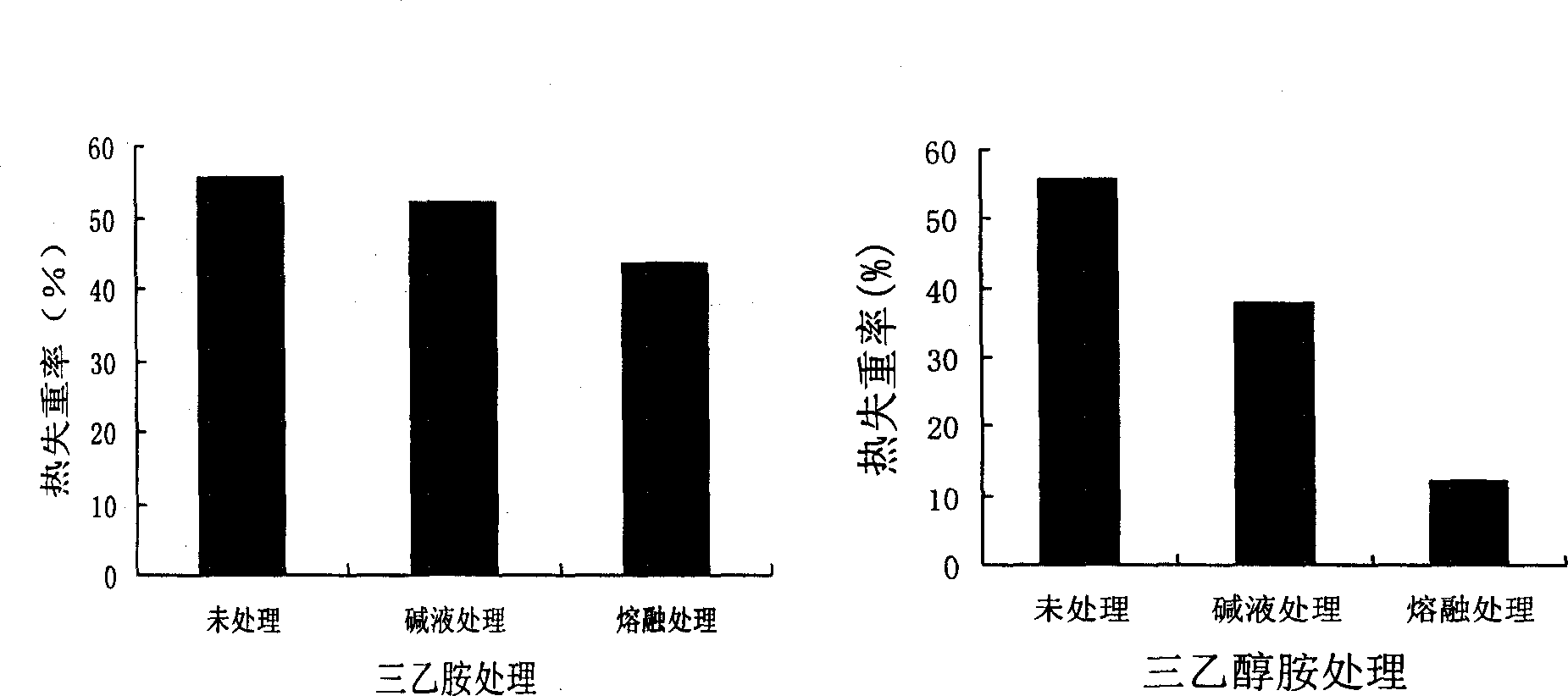

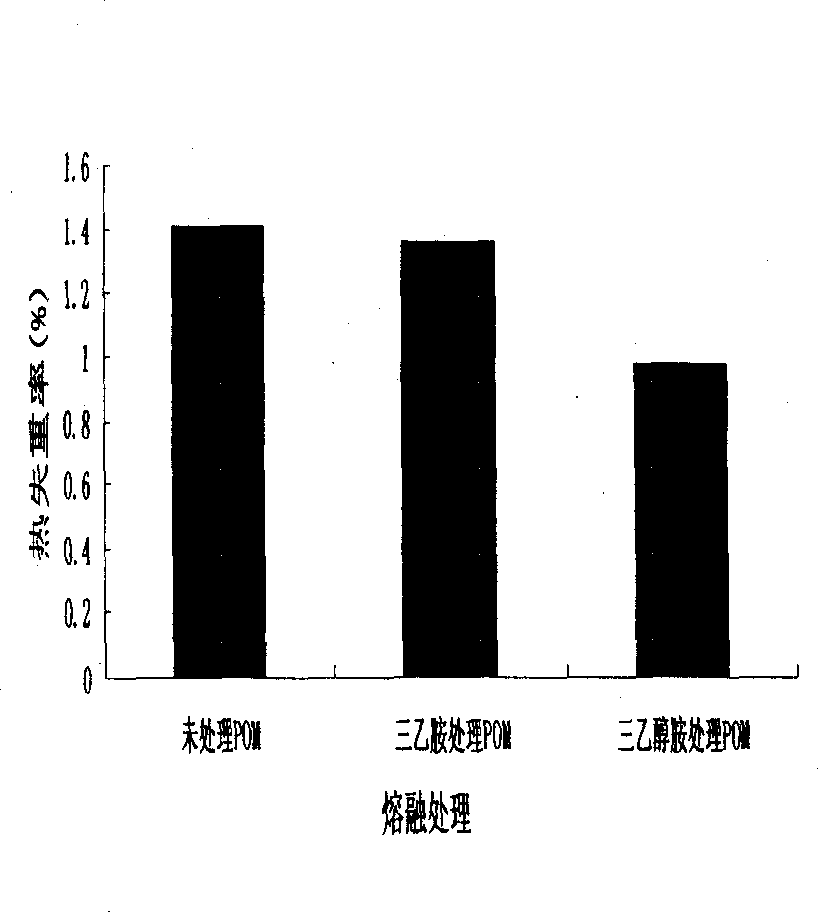

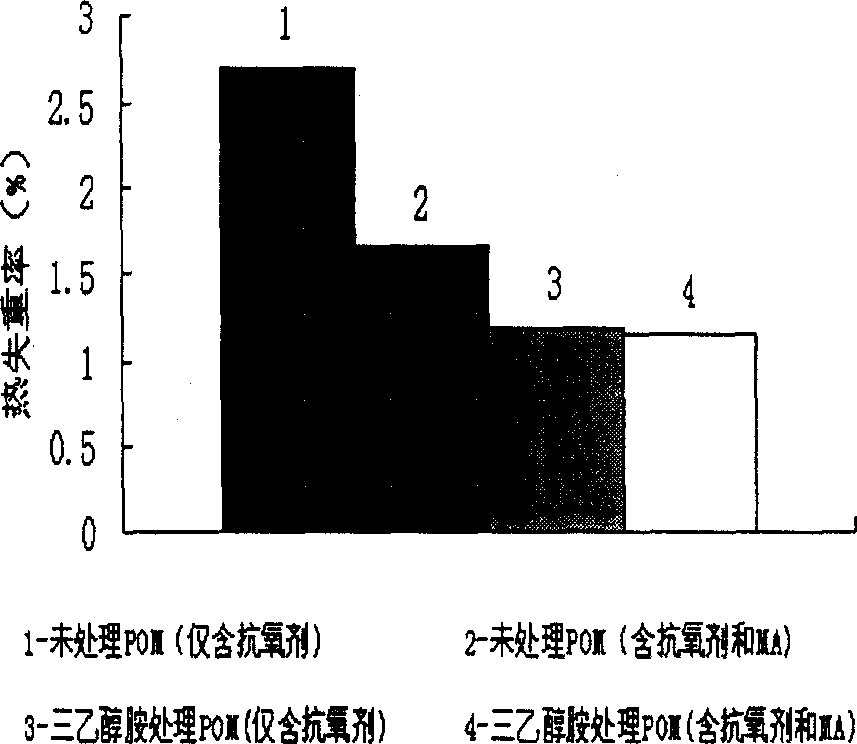

Method used

Image

Examples

Embodiment 1

[0057] Example 1 POM 10Kg, triethylamine 100g, water 100g, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 10g, magnesium oxide 5g, bis stearamide Mix 20g evenly, melt and knead with a vented twin-screw extruder, extrude and granulate. The barrel temperature of the extruder is 170-220°C, the screw speed is 40 rpm, and dried at 90°C for 3 hours.

Embodiment 2

[0059] POM 10Kg, triethanolamine 5g, water 600g, bis[3-(3-tert-butyl-5-methyl-4-hydroxyphenyl) triethylene glycol propionate 50g, calcium silicate 30g, pentaerythritol tris Stearic acid ester 5g is mixed evenly, adopts exhaust type twin-screw extruder to melt kneading, extrudes granulation. The barrel temperature of the extruder is 140-190° C., the screw speed is 90 rpm, and dried at 80° C. for 5 hours.

Embodiment 3

[0061] POM 10Kg, ammonia water (27wt%) 1000g, N,N'-hexylidene bis(3,5-di-tert-butyl-4-hydroxyl-hydrocinnamic amide) 50g, calcium carbonate 50g, glycerol monostearate 10g Mix evenly, use a vented twin-screw extruder to melt and knead, and extrude to granulate. The barrel temperature of the extruder is 150-220° C., the screw speed is 150 rpm, and it is dried at 90° C. for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com