Technical method for alloying surface of pure copper based plates

A technology of surface alloying and process method, applied in metal material coating process, pressure inorganic powder coating, coating, etc., can solve the problems of poor oxidation resistance, inability to be used as high-strength material, and low surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

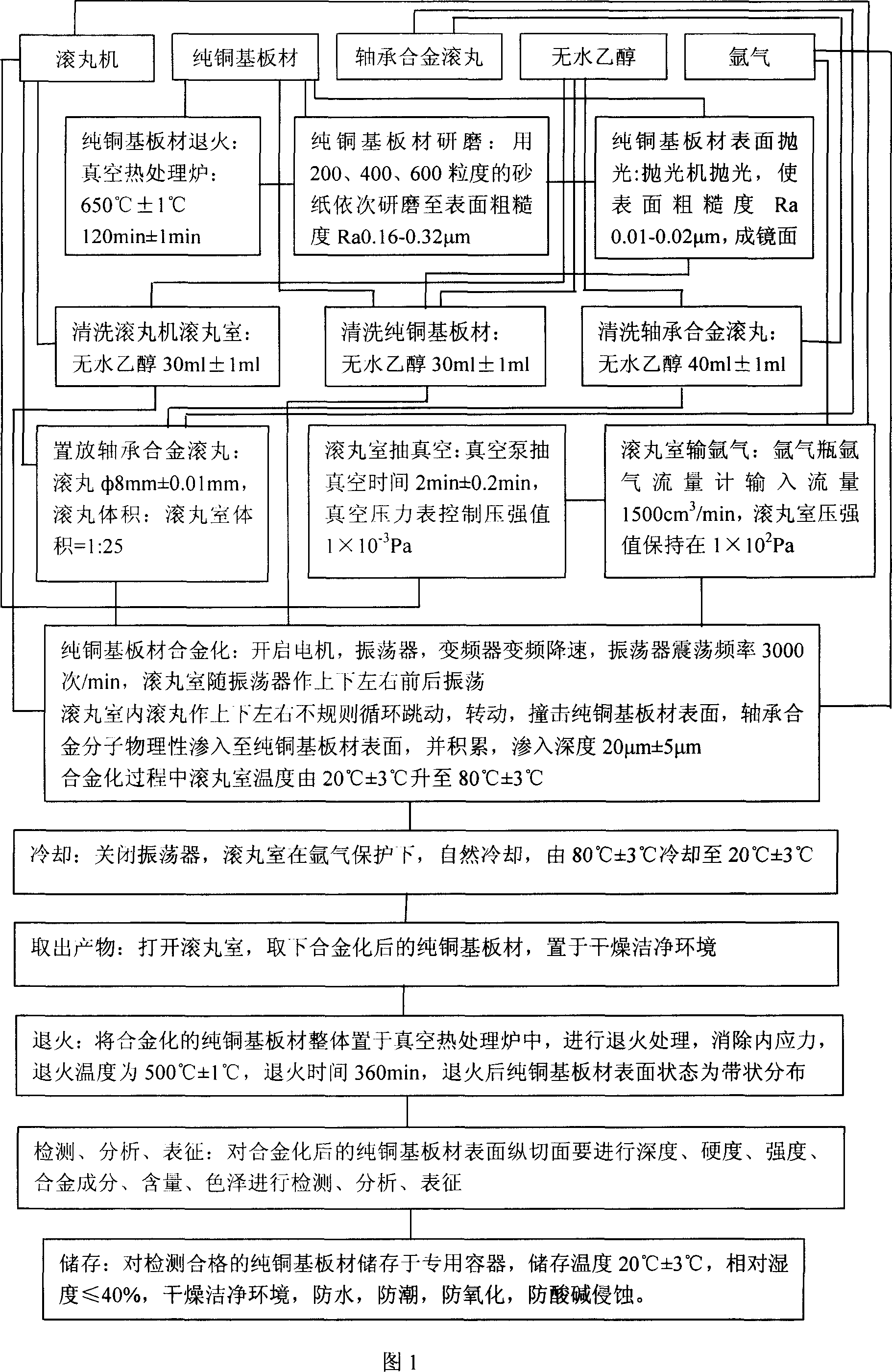

[0088] The present invention will be further described below in conjunction with accompanying drawing:

[0089] As shown in Figure 1, it is a flow chart of the process method, and each preparation parameter should be strictly controlled and operated in sequence.

[0090] The pure copper substrates, bearing alloy balls, anhydrous ethanol, and argon gas required for the preparation must be strictly selected, and the shape, size, purity, precision, roughness, and roundness shall be controlled to ensure the high precision of the process method sex.

[0091] Inert protective gas-argon has the function of protecting the atmosphere and expelling other harmful gases, so the delivery volume must be sufficient, and the pressure of the ball rolling chamber must be 1×10 2 Pa, and can ensure that the alloyed surface will not be oxidized under working conditions.

[0092] Before alloying, the pure copper substrate should be ground and mechanically polished to make the surface smooth and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com