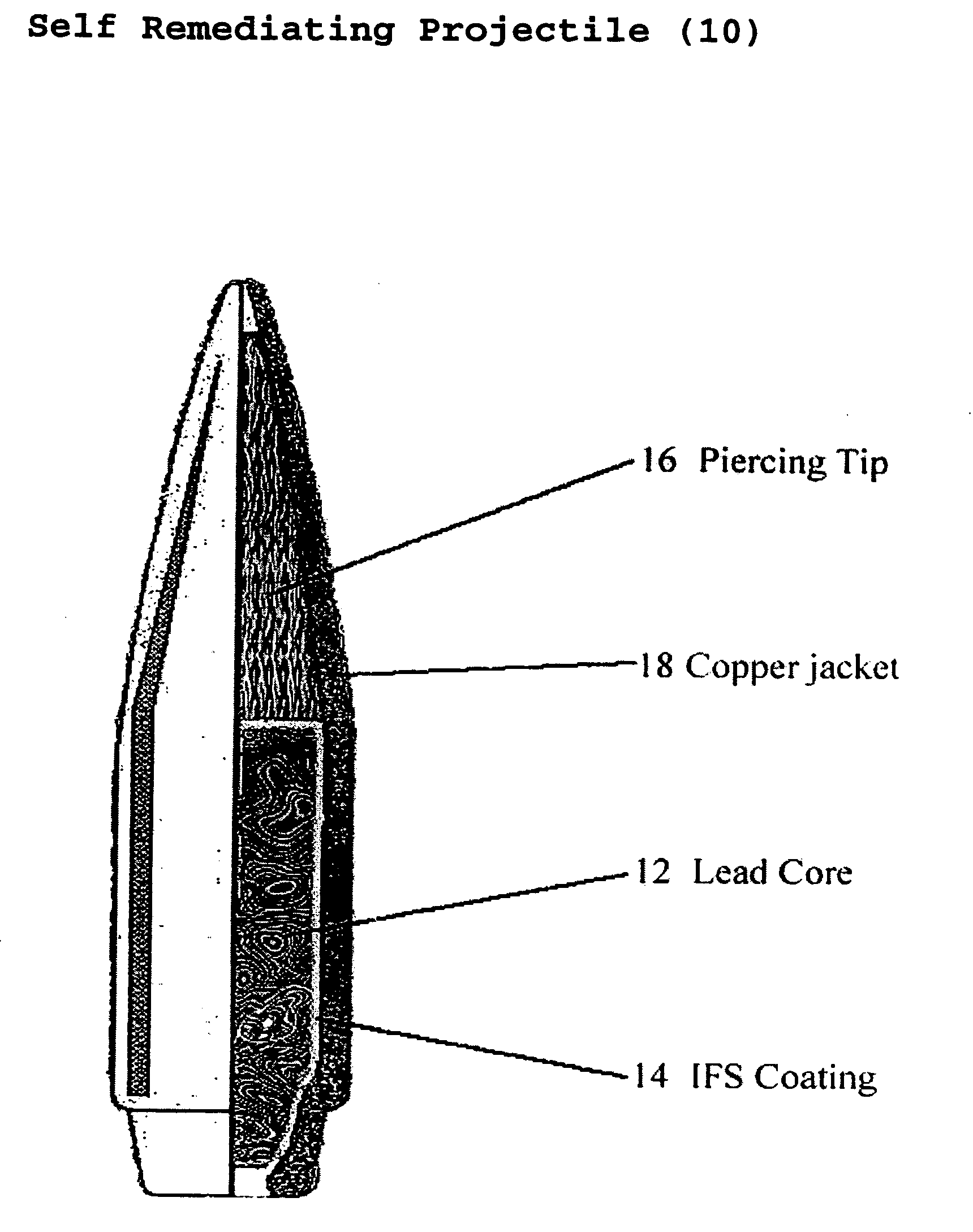

Self-remediating projectile

a self-remediation and projectile technology, applied in the field of ballistic projectiles, can solve the problems of significant pollution, large cost involved in the removal of this pollution, and inability to meet the requirements of the coating,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0044] A surface coating is prepared by forming a solution of (a) a linear copolymer polymer comprising poly[(methyl acrylate)x(tris-capped acrylic acid)y], where x:y is approximately 87:13 (100 parts by weight (pbw)), (b) ethyl acetate (100 pbw) and (c) propan-2-ol (100 pbw). This coating imparts moisture resistance to a coated metal article but, on immersion in water for more than a few hours, readily hydrates, crumbles and dissolves over a period of several days to weeks. Being a soluble acrylic polymer, it is intrinsically biodegradable.

[0045] The polymer solution is combined with a remediation agent known as Molecular Bonding System 3.1™ from Solucorp Industries: a 3:2:1 wt.-to-wt. mixture of technical grade calcium sulfide, calcium carbonate, and triple super phosphate) (200 pbw) and additional ethyl acetate (300 pbw) to form the IFS coating.

[0046] The IFS coating is applied to a US No. 8 lead—1.25% antimony alloy shot at a concentration of 1% by weight (dry weight) by a tum...

example 2

[0055] A surface coating is prepared by forming a dispersion of MBS 2.1™ (Solucorp Industries Ltd.) in polyvinyl acetate-polyvinyl alcohol, (PVAcx-PVAy, where the mole ratio x is >=65%). Specifically, a blend of 20% w / w / PVAc-PVA solution, MBS 2.1™, and ethyl acetate solvent are mixed together at the ratio 1:2:1 pbw. 10 gram of the resulting dispersion is applied to the underside of a normal commercial or biodegradable clay pigeon, such as those supplied by CCI International Ltd (of Priors Haw Road, Corby, Northants, UK). On drying, the weight of the standard sized clay pigeon should be within the weight range 100-110 grams and will carry 4-5 grams of an IFS reagent, which may be liberated by biodegradation and or weathering to release sufficient reagent to remediate approximately 2.0 to 2.5 grams of soluble lead or passivate the surface against corrosion of a much larger proportion metallic lead shot. The above dispersion may be modified into a sprayable paint or re-formulated into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com