Medical Resin Composition, Process For Producing Resin Composition and Process For Producing Molded Article

a technology of resin composition and molded article, which is applied in the field of medical resin composition, can solve the problems of adversely stimulating an oral cavity, affecting the function of the oral cavity, and affecting the fit between the mucosal surface and the denture base, and achieves the effects of reducing the adverse effect of the human body, preventing the leaching of irritative substances, and facilitating the use of human bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Spreading Test

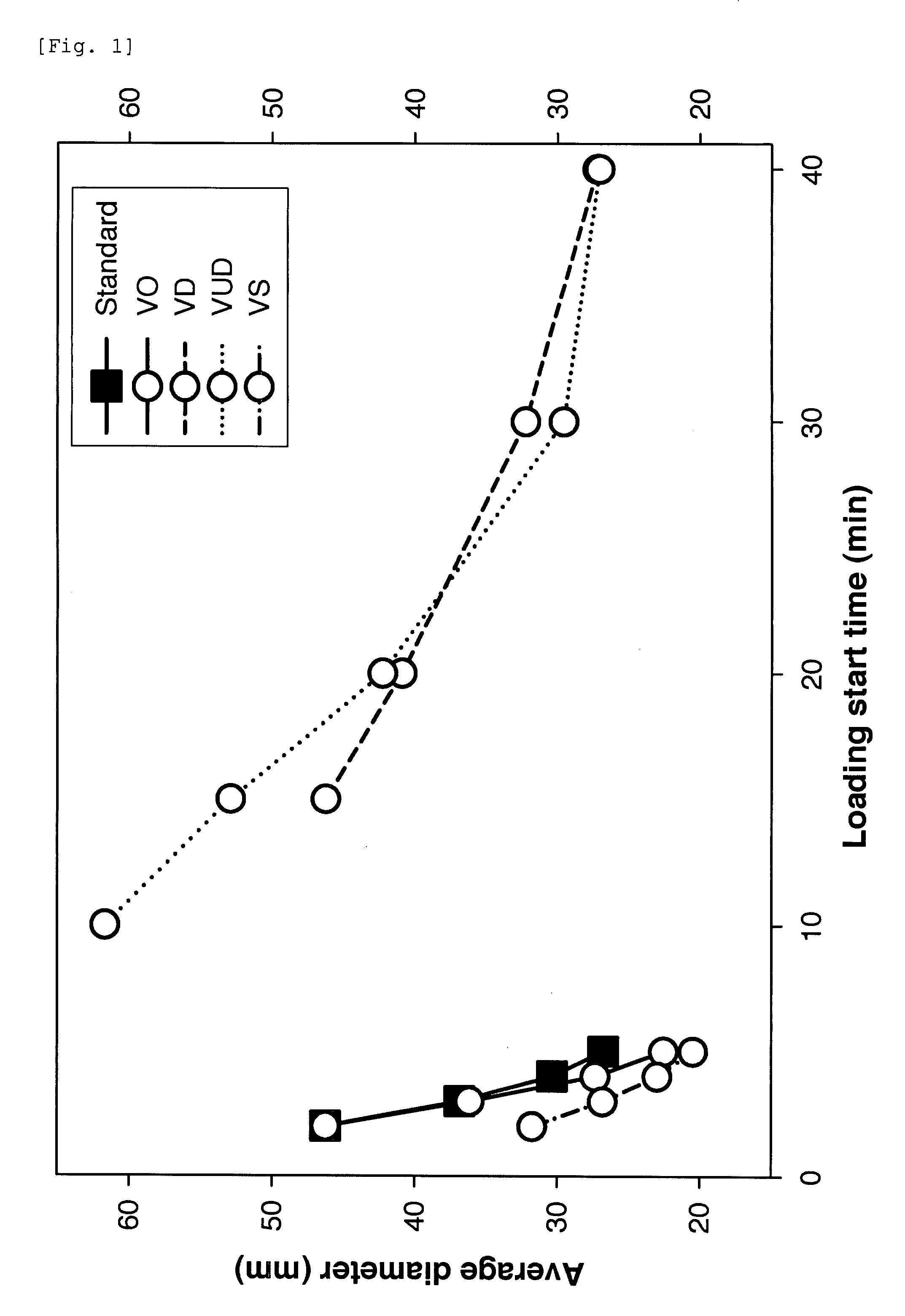

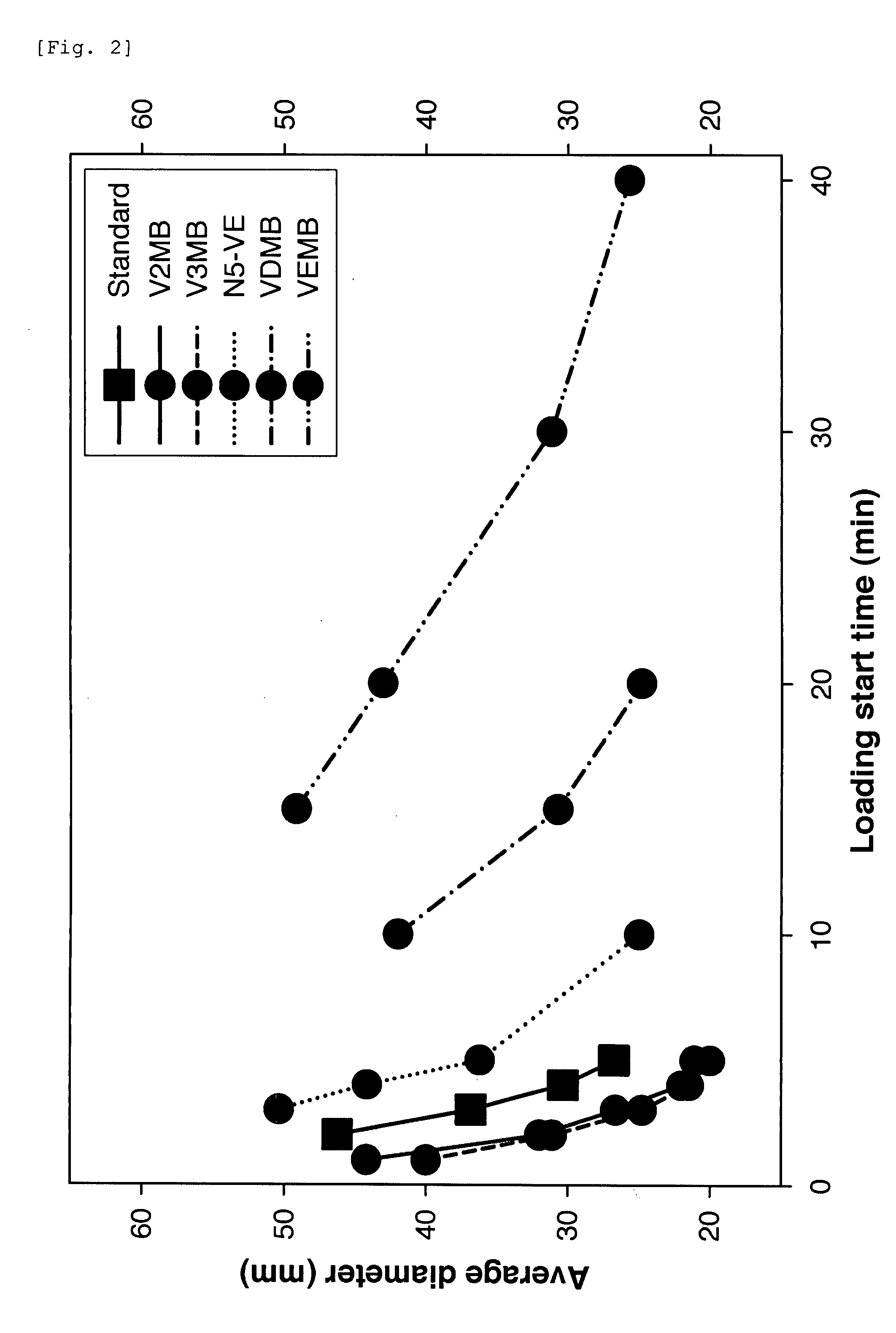

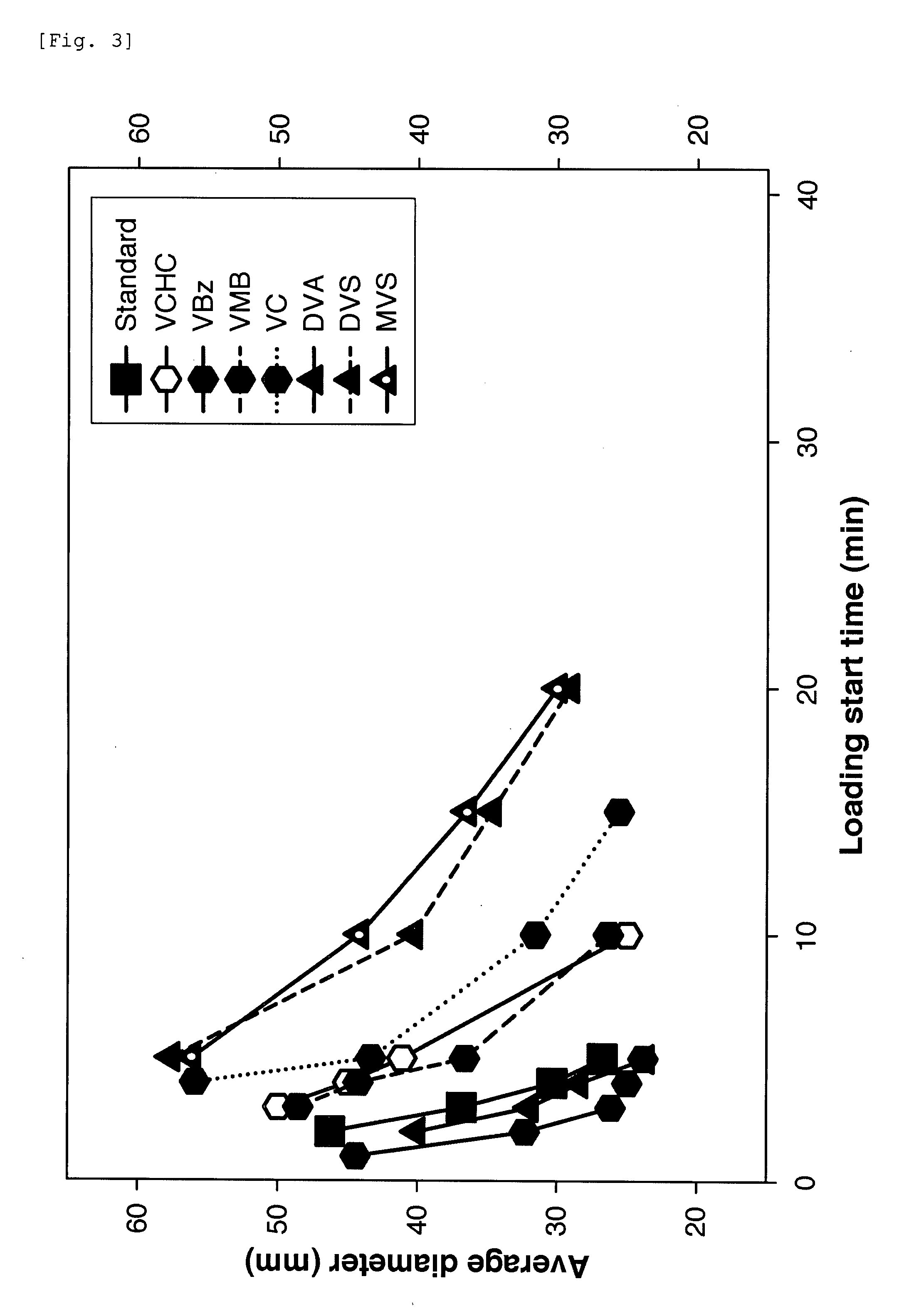

[0062] A spreading test was conducted in accordance with the above-mentioned method by using 2 g of a powder of poly(ethyl methacrylate) (PEMA) having an average particle diameter of about 40 μm as a powder comprising polymer (A) and 1.8 mL of liquids comprising various vinyl ester monomers (B) shown below containing 1% by weight of benzoyl peroxide (C: polymerization initiator) as a liquid. A weight average molecular weight of the PEMA measured by gel permeation chromatography (GPC) is about 400,000. The mixture of dibutyl phthalate and 15% by weight of ethanol (Standard) corresponds to the recipe of tissue conditioners, which are commercially available at present. If the result of a spreading test is the same as or close to that of the mixture, it serves as a standard for judging that the operativity in use as a tissue conditioner is good.

[Linear Alkyl Vinyl Esters]

[0063] Vinyl caprylate (VO: n=10: molecular weight 170.25)

[0064] Vinyl caprate (VD: n=12: molecular...

example 2

Rubber Hardness Test

[0087] A Shore C hardness was measured in accordance with the above-mentioned method by using 6 g of a powder of poly(ethyl methacrylate) (PEMA) the same as that of Example 1 as a powder of polymer (A) and 5 mL of liquids comprising various vinyl ester monomers (B) shown below containing 1% by weight of benzoyl peroxide (C: polymerization initiator) as a liquid.

[Linear Alkyl Vinyl Ester]

[0088] Vinyl caprylate (VO: n=10: molecular weight 170.25)

[Cycloalkyl Vinyl Ester]

[0089] Vinyl cyclohexanecarboxylate (VCHC: n=9: molecular weight 154.21)

[Aromatic Vinyl Esters]

[0090] Vinyl p-methylbenzoate (VMB: n=10: molecular weight 162.19)

[0091] Vinyl cinnamate (VC: n=11: molecular weight 174.2)

[Divinyl Esters]

[0092] Divinyl adipate (DVA: n=10: molecular weight 198.22)

[Other Liquids]

[0093] Mixture of dibutyl phthalate (n=16: molecular weight 278.35) and 15% by weight of ethanol (Standard)

[0094]FIG. 6 is a graph produced by plotting Shore C hardnesses as ordinate a...

example 3

Polymerization Test

[0095] 2 g of a powder of a methyl methacrylate (MMA: 40% by weight)-ethyl methacrylate (EMA: 60% by weight) copolymer having an average particle diameter of about 50 μm and 1 g of divinyl adipate (DVA) containing 1% by weight of benzoyl peroxide were mixed and then stirred for 30 seconds. A weight average molecular weight of the MMA-EMA copolymer measured by GPC was about 500,000. The resulting mixture was fed into a mold which can produce a specimen with dimensions 2 mm×2 mm×25 mm and was held at 100° C. for 10 min under a load of 3 ton. Thus, a polymerization reaction was allowed to proceed. After spontaneous cooling, the specimen taken out from the mold was left at rest in the air for one day and then was subjected to a three-point bending test (span: 20 mm, cross-head speed: 0.5 mm / min) with a universal testing machine (INSTRON 5544). Thus, flexural strength, flexural modulus, fracture energy and maximum deflection were measured. Further, samples before and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com