Metal/gallium nitride aluminum /gallium nitride lateral direction schottky diode with low current collection side effect and method of producing the same

A Schottky diode, aluminum gallium nitride technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the lateral Schottky diode current edge effect cannot be effectively alleviated, and it is difficult to reduce production costs. Increase the difficulty of production and other problems to achieve the effect of eliminating the possibility of failure or damage, reducing the current edge effect, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

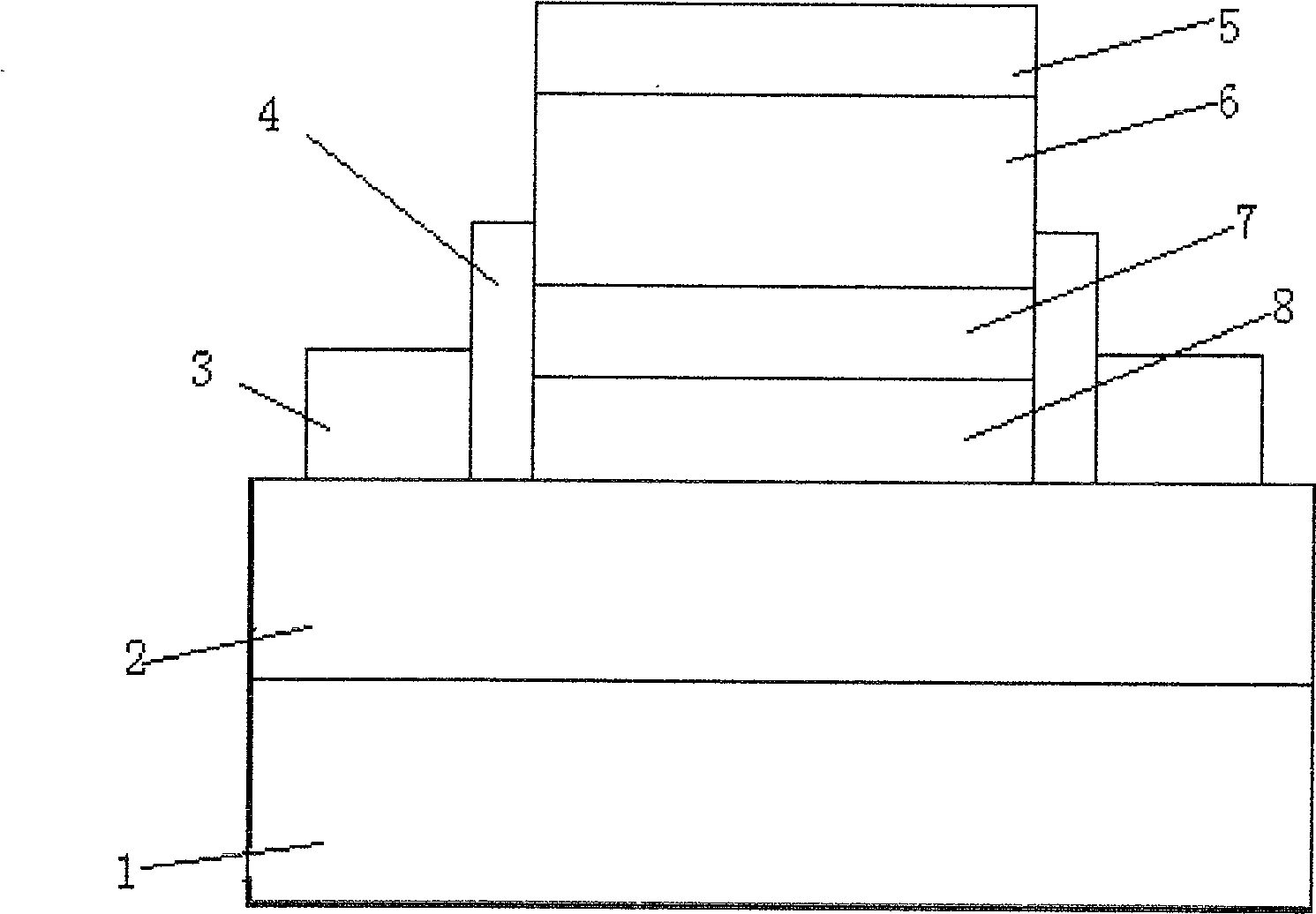

[0015] Embodiment 1: Complete the preparation in sequence according to the following steps: a) first use the epitaxial method to grow a gallium nitride layer on the substrate, wherein the substrate is selected from sapphire, and the epitaxial method is selected from the molecular beam epitaxy method, and the conditions during growth are the same as the existing . Then use the existing method to grow or deposit the positive electrode, the negative electrode and the mask respectively on the gallium nitride layer, wherein, the mask is deposited on the surface of the gallium nitride layer by using the plasma enhanced chemical vapor deposition method, depositing When the pressure is 1Pa, other conditions are the same as the existing ones, the mask is a silicon nitride mask; the negative electrode is deposited on the surface of the gallium nitride layer using the existing method, the negative electrode is an ohmic contact, and the contact layer is titanium aluminum alloy layer; the ...

Embodiment 2

[0016] Embodiment 2: Complete the preparation sequentially according to the following steps: a) first use epitaxy to grow a gallium nitride layer on the substrate, wherein the substrate is sapphire, and the epitaxy is molecular beam epitaxy. . Then use the existing method to grow or deposit the positive electrode, the negative electrode and the mask respectively on the gallium nitride layer, wherein, the mask is deposited on the surface of the gallium nitride layer by using the plasma enhanced chemical vapor deposition method, depositing When the pressure is 1.5Pa, other conditions are the same as the existing ones, the mask is a silicon nitride mask; the negative electrode is deposited on the surface of the gallium nitride layer using the existing method, the negative electrode is an ohmic contact, and the contact layer is titanium An aluminum alloy layer; an existing method is used to grow an aluminum gallium nitride layer on the surface of the gallium nitride layer; a tanta...

Embodiment 3

[0017] Embodiment 3: Complete the preparation sequentially according to the following steps: a) first use the epitaxy method to grow a gallium nitride layer on the substrate, wherein the substrate is sapphire, the epitaxy method is molecular beam epitaxy, and the growth conditions are the same as the existing . Then use the existing method to grow or deposit the positive electrode, the negative electrode and the mask respectively on the gallium nitride layer, wherein, the mask is deposited on the surface of the gallium nitride layer by using the plasma enhanced chemical vapor deposition method, depositing When the pressure is 2Pa, other conditions are the same as the existing ones, the mask is a silicon nitride mask; the negative electrode is deposited on the surface of the gallium nitride layer using the existing method, the negative electrode is an ohmic contact, and the contact layer is titanium aluminum alloy layer; the existing method is used to grow the aluminum gallium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com