Chemical passivation method for measuring minority carrier lifetime of crystalline silicon

A chemical passivation, minority carrier lifetime technology, used in semiconductor/solid-state device testing/measurement, single semiconductor device testing, semiconductor/solid-state device manufacturing, etc. and other problems, to achieve the effect of low cost, reduction of high temperature diffusion process, and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

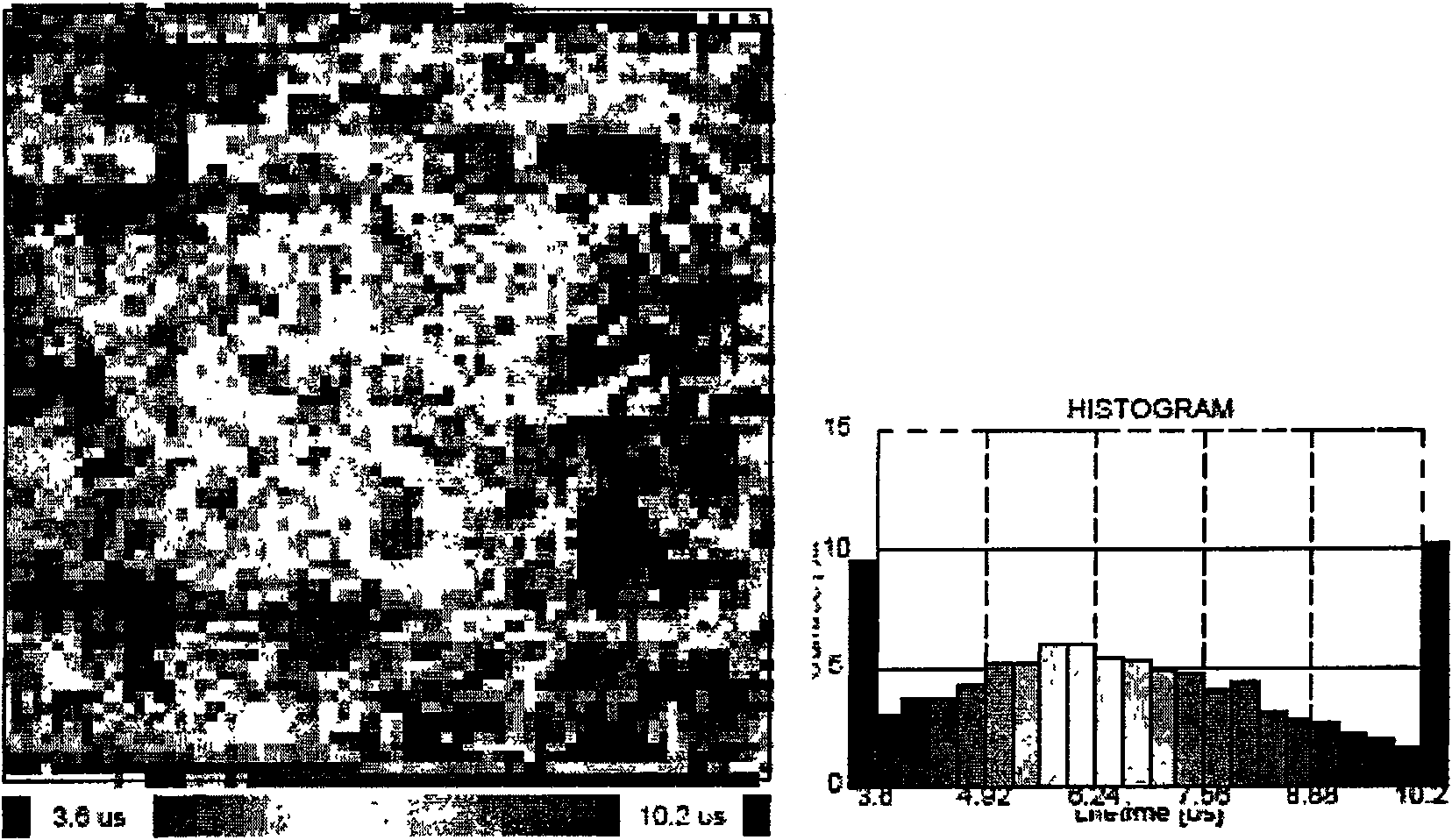

[0035] Take a P-type Czochralski monocrystalline silicon wafer imported from Korea, with a resistivity of 15 ohm cm, a thickness of 700 microns, and double-sided polishing. Two slices A and B were cut on the same silicon wafer. Since the two slices A and B are polished slices, there is no damage removal process. Carry out direct measurement respectively to A, B two respectively: the hydrogen fluoride passivation measurement of the present invention, and the iodine passivation test in United States Patent, patent number5580828.

[0036] Direct chip test: Two chips are placed directly on the sample stage of the microwave photoconductive attenuation quantum lifetime tester without any treatment, and then the minority carrier lifetime is tested to obtain the plane distribution of the minority carrier lifetime, and finally the average value of the crystalline silicon is obtained. Minor life expectancy.

[0037] High-concentration HF passivation among the present invention: 1) the ...

Embodiment 2

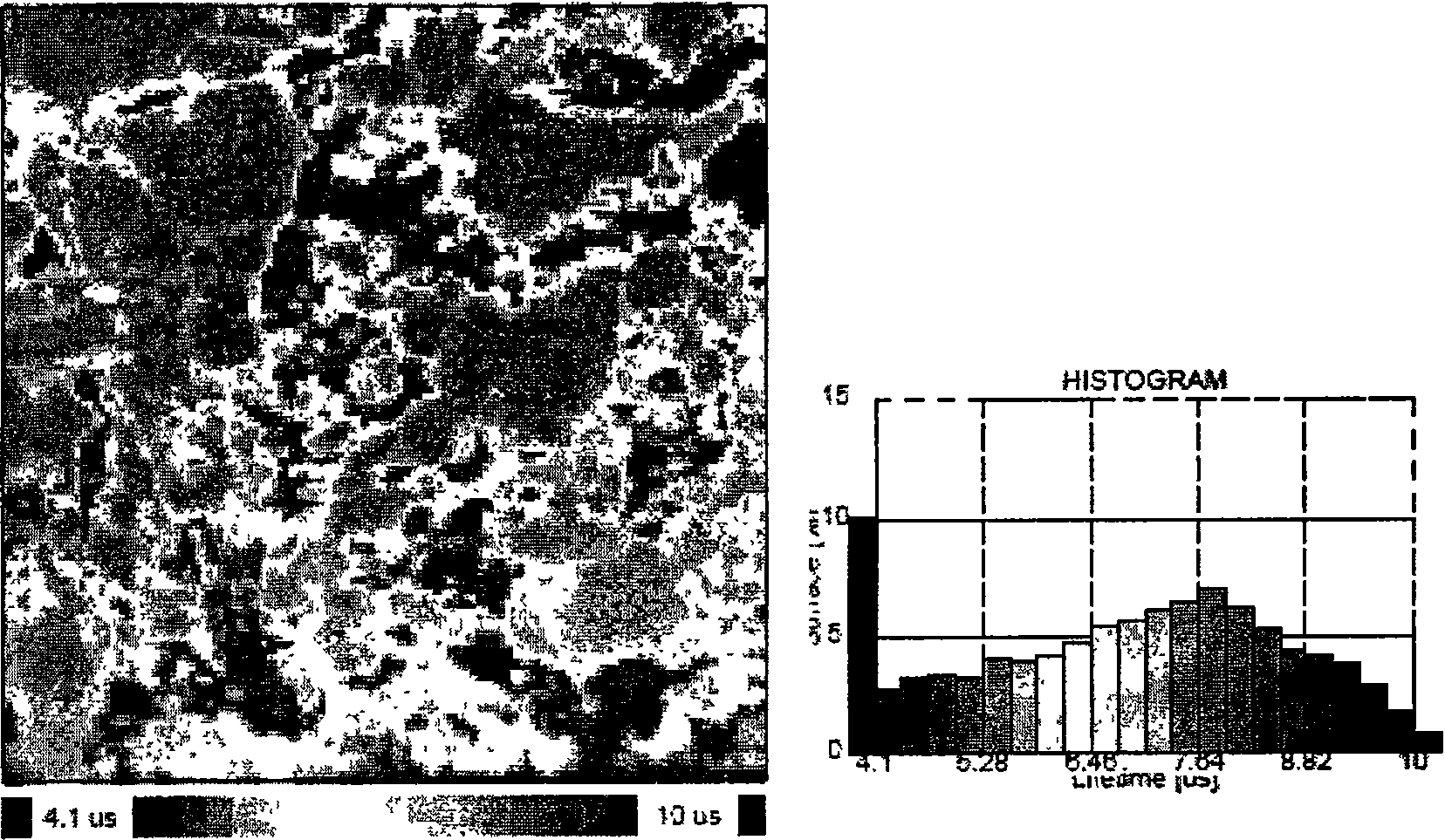

[0042] For P-type (100), cast polysilicon wafers with a resistivity of 1Ωcm and a thickness of 220 μm, phosphorus diffusion passivation is compared with the passivation method of the present invention. Firstly, the polysilicon wafer is pre-treated to remove damage: use hydrogen fluoride (HF) (39%): HNO 3 (75%):CH 3 A mixed solution of COOH (99%)=1:3:3 (volume ratio) was used to remove the damaged layer on two polysilicon wafers cut from the same cast polysilicon wafer at room temperature, and the etching time of the solution was 20 minutes. Then the two pieces were subjected to diffusion passivation and hydrogen fluoride (HF) solution passivation test in the present invention respectively.

[0043] One of the polycrystalline silicon wafers after the damage is removed is subjected to a passivation test according to the passivation method in the present invention: 1) the rinsed wafer is rinsed for 30s in a 20% concentration of diluted hydrogen fluoride (HF) solution; 2) the cry...

Embodiment 3

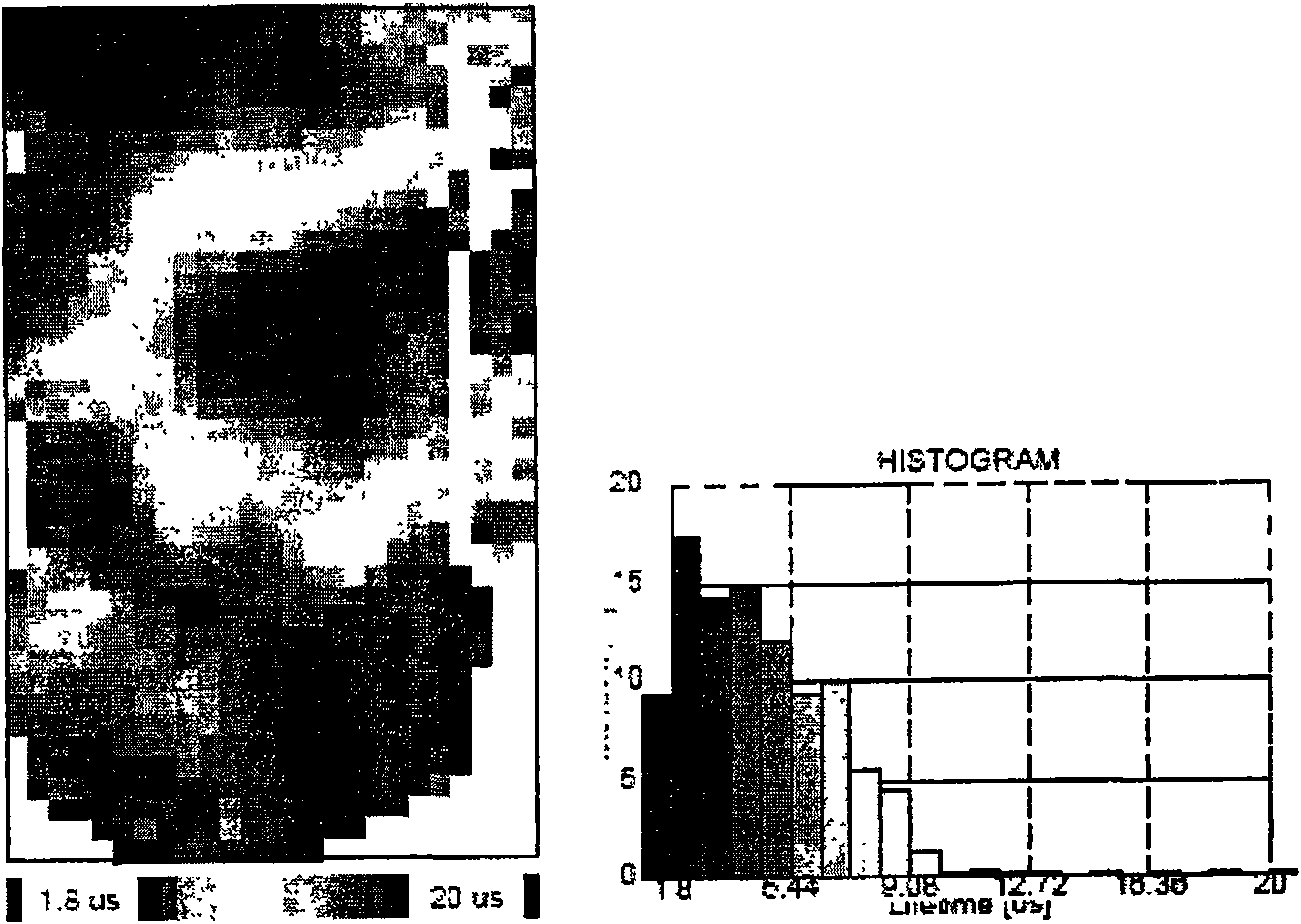

[0046] Utilize the passivation method of the present invention and United States Patent, the 1% iodine solution in patent number 5580828 carries out the test and comparison of the minority carrier life of the monocrystalline silicon wafer used in industrialized solar cell production respectively, P type (100) single crystal Silicon, resistivity 1Ωcm, thickness 220μm. This kind of sheet also has a 10-20 μm thick damaged layer on the surface, so pretreatment to remove the damaged layer is also required. The monocrystalline silicon wafer is put into the damage-removing and texturing equipment in the industrial production line, and the damage-removing and texturing are performed according to the conventional production process, and the textured wafer is taken out. Then according to the present invention and United States Patent respectively, 1% iodine solution (1g iodine is put in the dehydrated alcohol of 100ml) passivation in the patent number 5580828, the crystalline silicon ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com